International Yoga Day Observance: A Reflection of Tradition and Modern Wellness

On June 21, SRM University-AP marked International Yoga Day with commendable enthusiasm, drawing the active participation of faculty, students, and staff. This significant event, organised under the auspices of the Directorate of Student Affairs and the Directorate of Sports, not only highlighted the importance of yoga in contemporary life but also emphasised the unifying power of this ancient practice.

The ceremony commenced with a warm welcome address by Mr Anil Kumar Nigam, Director of Student Affairs, setting a positive tone for the day. Mr Nigam further remarked on the profound significance of International Yoga Day, he stated, “Yoga empowers individuals to take charge of their own well-being and enables them to stand strong in the face of adversities”

The celebrations featured a captivating demonstration of traditional yoga led by the yoga instructor, Ms Moni, followed by partner yoga and collective sessions involving faculty, staff, and students. These activities showcased not just the flexibility of the participants but also underscored the principle of unity between mind, body, and soul, fostering a sense of inner peace.

Registrar, Dr R Premkumar, in his address, imparted a poignant message on the essence of self-commitment as the foundation for any path one chooses to follow. He further remarked that “Yoga’s role in bringing about the well-being of oneself and society is profound,” underscoring the transformative power of yoga in achieving personal health and inner peace.

The event not only celebrated the timeless values of peace and harmony inherent in yoga but also reinforced the varsity’s commitment to fostering a holistic educational environment. Ms Sushmita Kumari, Assistant Director of Sports, expressed her heartfelt appreciation for the enthusiastic participation of all attendees and encouraged everyone to continue on their transformative journey of wellness and harmony.

- Published in News, Sports News, student affairs news

Exploring Wire Arc Additive Manufacturing

Wire Arc Additive Manufacturing (WAAM) is revolutionizing how we make metal components, especially when it comes to materials like 304L austenitic stainless steel—a popular choice in industries such as aerospace, automotive, and healthcare due to its durability and corrosion resistance. The research paper titled “Microstructural Characteristics and Properties of Wire Arc Additive Manufactured 304L Austenitic Stainless Steel Cylindrical Components by Different Arc Welding Processes” published by Dr Maheswar Dwivedy, Associate Professor, Department of Mechanical Engineering and his post-doctoral scholar Dr B Prasanna Nagasai explores this innovative manufacturing method in detail, focusing on how different welding techniques affect the end product.

Overall, this research indicates that WAAM, with its different welding techniques, can produce 304L stainless steel cylinders that potentially outperform those made by conventional forging, both in terms of material efficiency and mechanical properties. Such findings are significant as they point towards more sustainable and cost-effective manufacturing methods that do not sacrifice quality.

Abstract

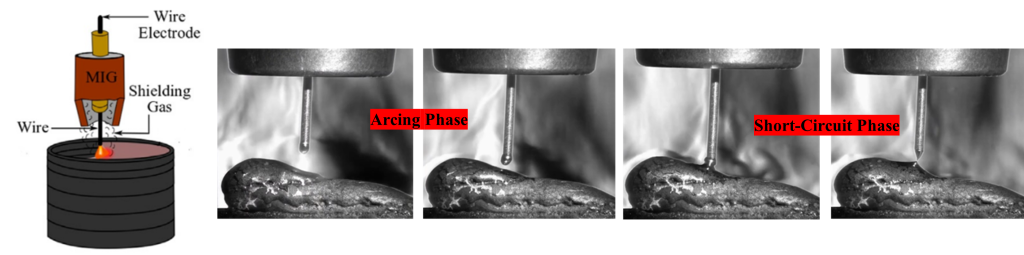

Wire arc additive manufacturing (WAAM) is an advanced additive manufacturing (AM) technology that offers low cost and high deposition rates, making it suitable for building large metal parts for structural engineering applications. However, various welding procedures result in differing heat inputs and repetitive heating treatments throughout the deposition process, which can affect the microstructural and mechanical characteristics of the parts. In the current study, cylindrical parts made of 304L austenitic stainless steel (ASS) were manufactured using the WAAM technique, employing both gas metal arc welding (GMAW) and cold metal transfer (CMT) processes. This study explores the correlation between WAAM techniques and their effects on the bead geometry, microstructure and mechanical properties. The paper presents detailed analyses of the microstructure using techniques such as optical microscopy, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD). The research findings suggest that the choice of arc welding process significantly affects the grain size, phase distribution, and defect formation within the 304L stainless steel, thereby influencing the mechanical properties and overall performance of the manufactured components. The WAAM-processed 304L ASS cylinders showed better performance compared to those manufactured using traditional industrial forging standards, indicating that WAAM-processed 304L ASS cylinders are suitable for industrial applications. This comprehensive evaluation provides insights into optimising welding processes for enhanced quality and performance of stainless steel cylindrical parts.

Highlights of the research

- Controlling heterogeneous microstructures in WAAM-processed 304L stainless steel is challenging.

- GMAW vs. CMT impacts on 304L ASS microstructure analysed.

- The upward growth of coarse austenite/ferrite morphologies is controlled by the wire retraction mechanism.

- CMT produced finer dendrites and more ferrite morphologies.

- WAAM 304L ASS components outperformed the wrought 304L ASS and forged 304L ASS.

Practical implementation/Social implications of the research

The practical implementation of Wire Arc Additive Manufacturing (WAAM) for 304L austenitic stainless steel could revolutionise multiple industries, including aerospace, automotive, medical devices, maritime, and energy, by allowing the production of complex, custom, and durable components with greater efficiency and reduced material waste. This shift not only promises economic benefits like cost reduction and job creation in advanced manufacturing sectors but also carries significant environmental advantages by minimising waste and the carbon footprint associated with traditional manufacturing processes. Furthermore, the technology enhances supply chain resilience by enabling local, on-demand production, which could be crucial during global disruptions. Socially, WAAM could increase access to customised medical aids in low-income regions, fostering greater equality. The adoption of WAAM thus holds the potential to impact manufacturing practices profoundly, driving innovation, sustainability, and inclusivity across various sectors.

Collaborations

Dr V Balasubramanian, Professor & Director, Centre for Materials Joining & Research (CEMAJOR), Annamalai University, Tamilnadu.

In the future, the research team plan to focus on developing Functionally Graded Materials (FGMs) of nickel and stainless steel using Wire Arc Additive Manufacturing (WAAM). This research will aim to leverage the unique properties of each metal to create components with tailored functional performance for demanding applications. Key challenges will include optimising material interfaces, controlling deposition processes, and ensuring structural integrity.

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

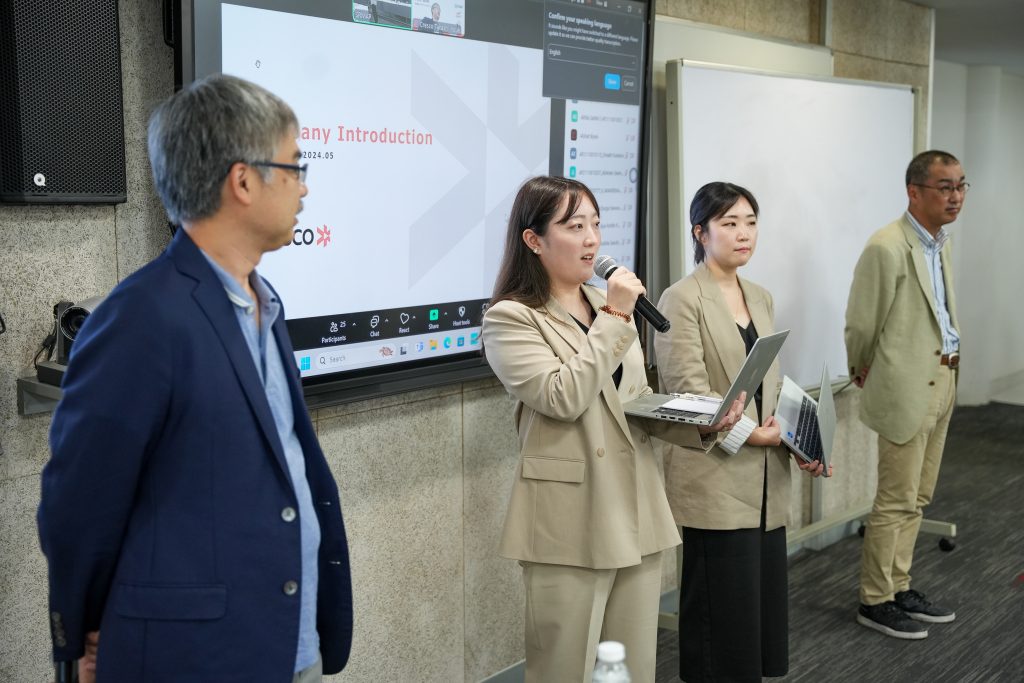

“Destination Japan”- An Indo-Japanese Alliance for International Recruitment of SRM AP Graduates

SRM University-AP, with its uniquely curated “Destination Japan” program for its highly skilled Engineering & Non-engineering Students, is an initiative by the university to address the growing demand for human resources in Japan. The ‘Destination Japan’ program provides well-equipped engineers with valuable industry skills and well acquainted with Japanese culture. Under the programme, students are trained in the Japanese language, Japanese traditions, and work culture from the first year onwards, which helps them easily assimilate into the country’s workforce. The initiative also welcomes reputed companies from Japan to directly hire skilled engineering graduates from core engineering fields to enhance their manpower.

SRM University–AP has also signed MOUs with multiple universities in Japan for faculty & student exchange programs, collaborative R&D projects, Hi-tech & innovative labs and other academic initiatives complementing the “ Destination Japan “ program.

To further enhance this mutual alliance, the Director of Corporate Relations & Career Services of SRM AP, Dr Vivekanandan M S, has visited prospective companies and industries in Hamamatsu, Japan, during which he presented the stellar record of engineering graduates being nurtured at the varsity and the possible partnership for recruitment and employment.

SRM University-AP has also signed an agreement with the Shizuoka Government to foster Indo-Japanese academic and recruitment partnerships. These partnerships enable internships in Japanese organisations, admissions to universities for higher studies, and good career placement opportunities for their students in Japan.

Under the “Destination Japan” program, direct campus recruitment has begun with the visit of recruitment teams from two reputed Japanese companies, Forum Engineering Inc. and CRESCO Ltd., to hire proficient engineering graduates. This is a remarkable accomplishment for the university to ensure international placements for its students.

A recruitment team of four from CRESCO Ltd, including the Managing Director, and a team of two from Forum Engineering Inc. visited the university campus. The team included engineers, HR Executives and other professionals.

Many more Japanese companies are lined up for campus visits & recruitment in the coming months.

In an interaction with the recruitment teams from Japan, Mr Satoshi Iwami, MD of CRESCO, remarked, “As we are facing a shortage of IT engineers not only in our company but all over Japan, and with the SRM AP harbouring excellent IT engineers, we decided that an alliance would greatly benefit both parties.”

Ms Saho Funahashi, UI/UX Designer at CRESCO, said, “The students’ Japanese skills have impressed me. SRM University-AP has helped students understand the practical way of studying engineering through its impressive resources. This would greatly benefit them in a techno-driven country like Japan.”

Mr Mitsutaka Sekino, Operating Officer at Forum Engineering and Director of Cognavi India stated, “Due to the population crisis, the Japanese economy is getting weaker, but we believe hiring an able workforce from SRM AP to Japan will help improve the economy. We have come to hire excellent students from the university, and I’m greatly impressed by their proficiency in Japanese and their work attitude.”

Mr Masahiro Koizumi, Senior Executive Officer at Forum Engineering and Managing Director of Cognavi India, opined, “We, from Forum Engineering, have come here with the intention of recruiting high-skilled engineers. Furthermore, the clients of Forum Engineering, the manufacturers of electrical and mechanical equipment in Japan, have been facing a shortage of engineers. They desire Indian students to come to Japan and help resolve the problem.”

This program is guided and driven by SRM Global Consulting Private Limited, a consulting company of SRM Group established in Japan. Speaking on this, Mr Sankar Karunanidhi, Country Manager, SRM Global Consulting, mentioned, “SRM Group has had a long-standing relationship with Japan for over 25 years. This association has helped us design this unique program and training for our university students”.

This flagship initiative by SRM University-AP is helping Japan alleviate its labour shortage in various industries. Highly skilled graduates from India can get lucrative placements in Japan, ensuring a good work-life balance and career growth opportunities. SRM University–AP, continuing its success of placing students in Japan with the dedicated program and the team behind Destination Japan, envisions placing a minimum of 120 Highly Skilled students in Japan year-on-year.

Vice Chancellor of SRM University-AP, Prof. Manoj K Arora, said this remarkable venture by the two parties would enrich the student’s academic experience, moulding them into global citizens with exceptional industry acumen. “We have established a prolific alliance with Japan. We plan to extend our collaborations to place our students in Taiwan, Canada, Germany and other European countries,” stated the head of the institution.

The continuous dedication and support from the team’s leading both nations guarantee prospective Indian graduates a once-in-a-lifetime opportunity to secure their dream careers in Japan.

- Published in CR&CS, CR&CS NEWS, Departmental News, News

Dr Chinmoy Das’s Groundbreaking Research Unveils Promising Discoveries

Dr Chinmoy Das, Assistant Professor at the Department of Chemistry at SRM University-AP, has made an impactful contribution with the publication of his research paper, “Insights into the Mechanochemical Glass Formation of Zeolitic Imidazolate Frameworks” in the prestigious Angewandte Chemie International Edition with an impact factor of 16.6. His paper unveils a rapid, eco-friendly, and efficient mechanochemical approach to transform glasses from their crystalline zeolitic imidazolate frameworks. This pioneering work opens new doors for sustainable and effective glass formation, showcasing the power of innovation in the field of chemistry.

Abstract:

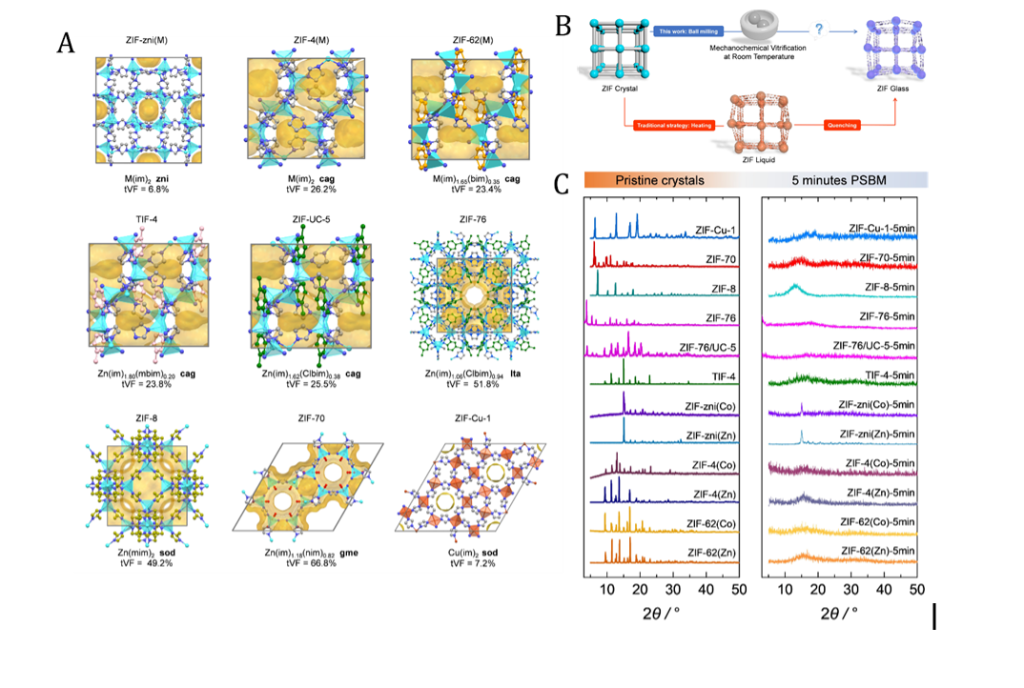

We describe a rapid, ecofriendly, and efficient mechanochemical approach to transform glasses from their crystalline zeolitic imidazolate frameworks (ZIFs). We exposition mechanochemical technique through which the traditional melt-quench preparation of glassy phases can be replaced. In this study, we explore that Zn(II), Co(II), and Cu(II)- based crystalline ZIFs transformed into the glassy phases within five minutes through the mechanical ball milling technique. The appearance of glass transition temperature(T g ) upon mechanical milling of crystalline states demonstrated by different characterization techniques, such as X-ray powder diffraction (XRPD), differential scanning calorimetry (DSC), simultaneous thermogravimetric and differential thermal analyses (TG/DTA), scanning electron microscopy (SEM), X-ray total scattering and its deduced pair distribution functions (PDFs). We characterized the porosity and density of the glassy phases through CO 2 gas sorption techniques which aligned with the observation of thermal, structural, and textural features of the ZIFs after varying ball milling times beyond five minutes.

Practical implementation

We can prepare bulk ZIF glasses within five minutes of the mechanochemical approach that will guide the greater feasibility to produce the glass materials for industrial implications. In addition, the greater the accessibility of glassy materials, the greater the fabrication of glassy materials-based device fabrication.

Collaborations

This article has been published with the collaboration of Prof. Sebastian Henke (Henke Group), Department of Chemistry and Chemical Biology, TU Dortmund University, Dortmund, Germany.

Future Research Plans

Recently, we established our research group in SRM University-AP, and our group has started to explore an emergent research area of crystal-glass composite materials towards the applications of atmospheric water harvesting, solid-state electrolytes (Alkali and Alkaline metal ions-based), photovoltaics, and conversion of gaseous Carbon-dioxide molecules to industrially relevant liquids, such as methanol or ethanol.

- Figure 1. (A) Single crystal structures of various ZIFs indicated in the figure. (B) Schematic representation of the traditional route to ZIF glass formation (red line) and the mechanochemical vitrification approach followed in this work (blue line). (C) PXRD patterns of the pristine ZIF polycrystalline materials and after five minutes of mechanical ball milling.

- Published in Chemistry-news, Departmental News, News, Research News