Recent News

- Unveiling Findings on Thermo-Mechanical Behaviour of FGM Sandwich Plates April 26, 2024

In a significant advancement in the field of material engineering, Dr Supen Kumar Sah, an esteemed Assistant Professor from the Department of Mechanical Engineering, has published a groundbreaking research paper.

In a significant advancement in the field of material engineering, Dr Supen Kumar Sah, an esteemed Assistant Professor from the Department of Mechanical Engineering, has published a groundbreaking research paper.The study, titled “Effect of Bi-Directional Material Gradation on Thermo-Mechanical Bending Response of Metal Ceramic FGM Sandwich Plates Using Inverse Trigonometric Shear Deformation Theory,” appears in the prestigious International Journal of Structural Integrity.

Dr Sah’s research provides new insights into the behaviour of Functionally Graded Materials (FGMs) under thermal and mechanical loads, which is crucial for the design of advanced engineering structures. His work employs an innovative inverse trigonometric shear deformation theory to analyse the bending response of metal-ceramic FGM sandwich plates, offering a more accurate prediction of their performance in real-world applications.

This publication not only highlights the cutting-edge research being conducted at SRM University but also positions Dr Sah as a leading figure in the application of FGMs in structural engineering. The findings from this paper have the potential to influence the design and optimization of materials used in various industries, from aerospace to automotive.

Abstract

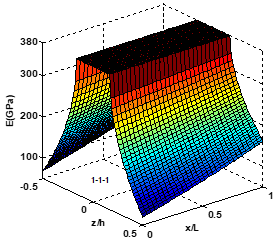

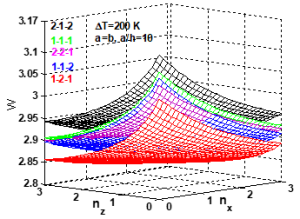

The purpose of this study is to investigate the bending analysis of metal (Ti-6Al-4V) ceramic (ZrO_2) functionally graded material (FGM) sandwich plate having material property gradation along length and thickness direction under thermo-mechanical loading using inverse trigonometric shear deformation theory (ITSDT). Mechanical and thermal properties of BDFGM sandwich plates are considered temperature-dependent in the present study. Analytical solution for bending analysis of FGM plate has been carried out using Hamilton’s principle and Navier’s solution.

The present study shows that centre deflection, normal stress, and shear stress are significantly influenced by temperature-dependent material properties, bi-directional gradation exponents’ geometrical parameters, sandwich plate layer thickness, etc.

Title of the Research Paper in the Citation Format

Sah, S. K., Ghosh, A. (2024). Effect of Bi-Directional Material Gradation on Thermo-Mechanical Bending Response of Metal Ceramic FGM Sandwich Plates Using Inverse Trigonometric Shear Deformation Theory. International Journal Structural Integrity. DOI: 10.1108/IJSI-02-2024-0016

Collaborations

Prof Anup Ghosh, Indian Institute of Technology Kharagpur, India

Future Research Plans

Modelling and Analysis of porous uni and multi-directional Functionally Graded Material (FGM) plates to obtain the impact of porosity distributions over structural responses.

Analytical & Finite Element Solution for static and dynamic response of FGM sandwich plates employing non-polynomial shear deformation theories under elastic foundation.

Pictures Related to the Research

Continue reading →

- Breakthrough in Lead-Free Brass Manufacturing: Patent Granted to Prof. G. S. Vinod Kumar March 19, 2024

The Department of Mechanical Engineering are excited to share a significant milestone achieved in the field of material science and metallurgy. Prof. G S Vinod Kumar, Professor and Head of the Department, has been granted a patent jointly with Titan Company, Bangalore, for the invention “METHOD OF MANUFACTURING LEAD-FREE BRASS” (Patent Grant Number: 452003). This industrial patent was created through a collaboration between SRM University-AP and Titan Company Limited.

This groundbreaking discovery not only transforms the manufacturing of lead-free brass, but it also highlights the collaborative spirit that drives advances in materials engineering.

Abstract

The present disclosure relates to a field of material science and metallurgy. In particular, the present disclosure discloses a method for manufacturing lead-free brass alloy. The method includes preparation of first master alloy by melting copper and a transition element, and a second master alloy by mixing molten zinc and molten copper. The lead-free brass is obtained by meting a predetermined proportion of the first master alloy and second master alloy along with elemental copper in a furnace under an argon atmosphere. The lead-free brass alloy is then subjected to a precipitation hardening process to improve hardness. The lead-free hard brass alloy containing titanium exhibits improved hardness in comparison to bare lead-free brass mainly due to the presence of intermetallic nanoscale precipitates, which are distributed throughout the lead-free brass matrix.

SRM University-AP continues pushing the limits of scientific discovery and industrial innovation.

Continue reading → - Metallurgical Study on Fusion Welding of Aluminium and Magnesium March 14, 2024

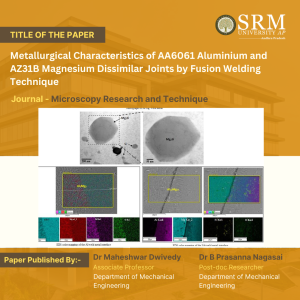

In a significant scientific endeavour, Dr Maheshwar Dwivedy, Associate Professor in the Department of Mechanical Engineering, and Dr B Prasanna Nagasai, Post-Doctoral Researcher have jointly authored a research paper titled “Metallurgical Characteristics of AA6061 Aluminium and AZ31B Magnesium Dissimilar Joints by Fusion Welding Technique”. Their work delves into the metallurgical properties of dissimilar joints formed by fusion welding between AA6061 aluminium and AZ31B magnesium.

In a significant scientific endeavour, Dr Maheshwar Dwivedy, Associate Professor in the Department of Mechanical Engineering, and Dr B Prasanna Nagasai, Post-Doctoral Researcher have jointly authored a research paper titled “Metallurgical Characteristics of AA6061 Aluminium and AZ31B Magnesium Dissimilar Joints by Fusion Welding Technique”. Their work delves into the metallurgical properties of dissimilar joints formed by fusion welding between AA6061 aluminium and AZ31B magnesium.The study, published in the esteemed Q1 journal “Microscopy Research and Technique”, sheds light on the intricate interactions between these two dissimilar materials. By employing advanced microscopy techniques, the researchers meticulously examined the weld interfaces, grain structures, and elemental compositions. Their findings contribute to our understanding of the joining behaviour and intermetallic formation in such hybrid joints.

This collaborative effort exemplifies SRM University – AP’s commitment to cutting-edge research and interdisciplinary exploration. As the scientific community continues to unravel the mysteries of material behaviour, Dr Dwivedy and Dr Nagasai’s work stands as a beacon of knowledge and innovation.

Stay tuned for more updates on this groundbreaking research!

Abstract

Aluminium (Al) and magnesium (Mg) alloys are extensively used in the automobile sector because of their high strength-to-weight ratio, excellent castability, low density and simplicity of recycling. Al-Mg structures that automotive uses have a big chance of lowering their weight. Although there is a significant opportunity for substantial cost reduction, the use of magnesium in aluminium structures remains restricted. This study aims to weld 3 mm-thick rolled sheets of AA6061 Al and AZ31B Mg alloy using the cold metal transfer (CMT) arc welding process. Three different filler wires (ER1100, ER4043, and ER5356) were used in the experiment. In this article, the mechanical and microstructure characteristics of Al/Mg dissimilar joints manufactured by CMT are evaluated and discussed in depth. Optical microscope (OM), scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDX), and X-ray diffraction were all used to analyse the CMT-welded Al/Mg dissimilar joints. Of the three filler wires used, ER4043 (Al-5%Si) filler wire yielded defect-free sound joints due to the presence of Si, which improves the flow ability of molten filler during welding. The Al/Mg dissimilar weld still produced the Mg-rich intermetallic (IM) Al12Mg17 and the Al-rich IM Al3Mg2. The surfaces of the fractured area of the CMT-welded Al/Mg dissimilar joints revealed the presence of the Mg-rich intermetallics (Al12Mg17), which is responsible for the decrease in tensile strength. The reduction of intermetallics, particularly of Mg-rich intermetallics (Al12Mg17) is important for improving joint strength.

Highlights

- Cold metal transfer (CMT) arc welding was used to control the Al-Mg-rich intermetallics in the Al/Mg dissimilar joints.

- The microstructure, morphology and phase composition of the welded joints were studied by OM, SEM, TEM, EDS and XRD.

- The weld metal and AL substrate are joined with a strong interface, while the weld metal and Mg substrate are joined with an epitaxial solidification area where the intermetallic compounds of Mg2Al3, Mg17Al12 and Mg2Si are generated.

- The weld metal on the Mg side experienced a brittle fracture, with a continuous distribution of Mg2Al3, Mg17Al12 and Mg2Si.

Explanation of Research in Layperson’s Terms

Al and Mg alloys are extensively used as light metals in engineering due to their advantageous characteristics, including high strength-to-weight ratio, cheap casting costs, low density, excellent machinability, and simple recyclability. Often, each of these materials fails to meet the criteria for lightweight buildings. Consequently, there is a high need for a significant quantity of Al/Mg hybrid structures in many industrial sectors with a particular emphasis on the automotive industry. Choosing the appropriate filler material for joining Al and Mg is crucial for creating robust weldments. The main difficulty in welding dissimilar metals like aluminium and magnesium lies in the formation of inflexible and brittle intermetallic compounds (IMCs) like Mg2Al3 and Mg17Al12, which severely affect the joint’s strength. When it comes to melting points, magnesium is at 650°C and aluminium is at 660°C. Based on the Mg-Al binary phase diagram, the compounds Mg2Al3 and Mg17Al12 can be produced at 450 and 437°C by eutectic reaction. Hence, the primary challenge in Al/Mg dissimilar welding is effectively suppressing the growing number of IMCs. Similarly, minimising energy input and utilising the appropriate chemistry of wire are the primary methods for decreasing the formation of IMCs and improving joint strength.

CMT is an advanced arc welding process which comes under controlled short circuiting transfer mode. The CMT welding cycle consists of two phases, i.e. the arcing phase and short circuit phase. In arcing phase, the filler wire gets melted and it forms as a droplet at the tip of the filler wire. In short circuiting phase, the droplet bridges the gap between the electrode and the weld pool. Once the short circuiting takes place, the filler wire gets retracted backward due to the retraction force and the droplet is detached from the filler wire. In conventional short circuiting transfer mode, the electromagnetic pinch force assists in detaching the droplet from the filler wire and thereby high heat input is produced by means of the short current. Where as in CMT short circuit transfer mode, the welding current is decreased to a lower value whenever a short circuit signal is sensed by the power source and the droplet gets separated from the filler wire with the help of the retraction force that is generated during the backward movement of the filler wire. Finally, the heat input is reduced to a lower value with this metal transfer mode. So, the CMT arc welding process was used to join the 3 mm-thick rolled sheets of AA6061 Al and AZ31B Mg alloy dissimilar materials. This article details the microstructural characteristics of an Al/Mg dissimilar joint. The CMT process controlled IMCs in the Al/Mg dissimilar joint and increased weld metal hardness compared to base metal.

The title of Research Paper in the Citation Format

aAddanki Ramaswamy, *aBellamkonda Prasanna Nagasai, aMaheshwar Dwivedy, Sudersanan Malarvizhi, Visvalingam Balasubramanian, Metallurgical Characteristics of AA6061 Aluminium and AZ31B Magnesium Dissimilar Joints by Fusion Welding Technique, Microscopy research and technique, 2024. DOI: 10.1002/JEMT.24510.

Corresponding Author: Bellamkonda Prasanna NagasaiCollaborations

Dr. V. Balasubramanian, Professor & Director, Centre for Materials Joining & Research (CEMAJOR) Annamalai University, Annamalai Nagar-608002, Tamilnadu

Future Research Plans:

Planning to work on Fusion Welding (CMT, MIG, TIG, LASER, PLASMA and EBW) and Solid State Welding Processes (FSW, Rotary Friction Welding, Resistance Spot Welding, Magnetic Pulse Welding). Working on Additive Manufacturing (Wire Arc Additive Manufacturing on Metals, 3D Printing on Plastics), Cladding and Machinability. Characterisation, Tribology, and Corrosion. Steels and alloys, Aluminum, Nickel and Titanium Alloys.

Continue reading → - Pioneering the Future: Ultrafine MgAl2O4 Particle-Stabilised Mg-3Ca Alloy Foams February 28, 2024

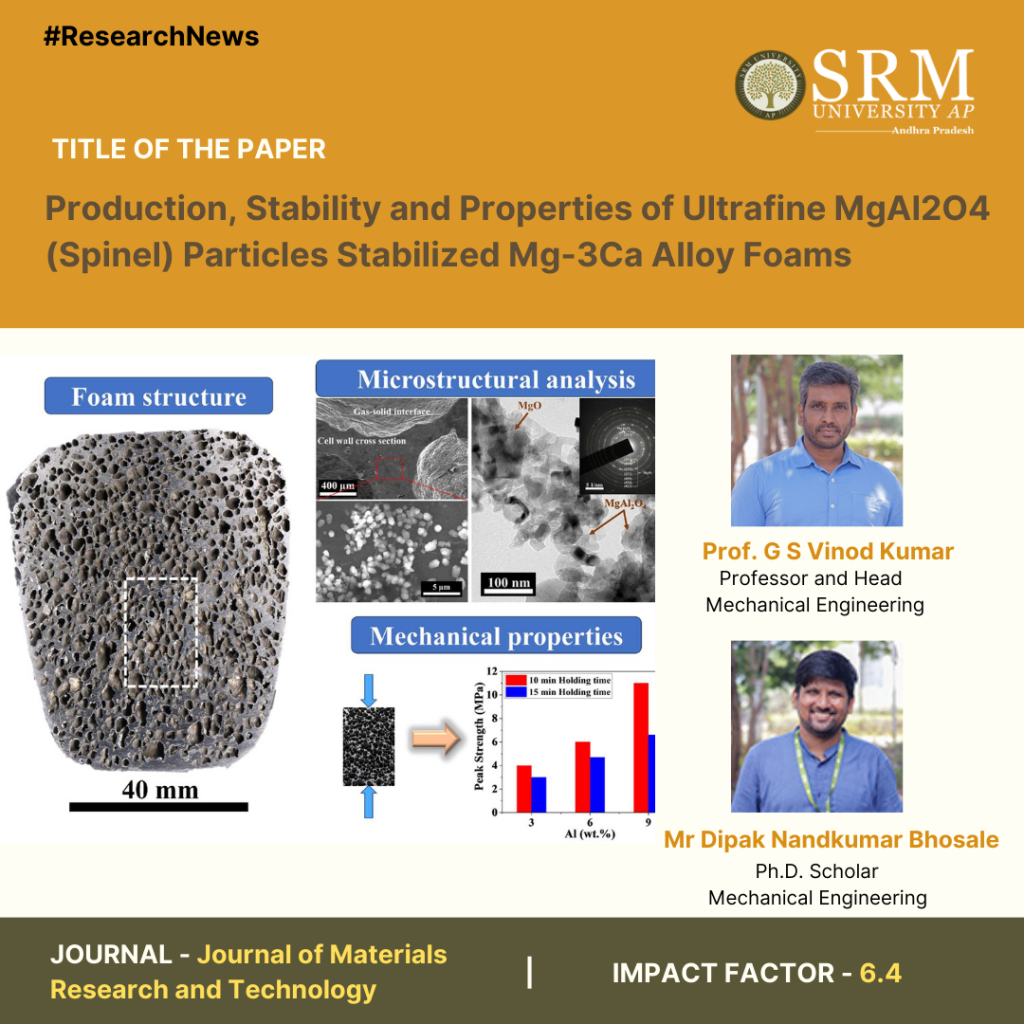

The Department of Mechanical Engineering is thrilled to announce a significant breakthrough in materials science has been achieved through the diligent research efforts of Prof. G S Vinod Kumar, Professor and Head of the Department and his Ph.D. scholar, Mr Dipak Bhosale in their latest paper, “Production, stability and properties of ultrafine MgAl2O4 (Spinel) particles stabilized Mg-3Ca alloy foams”. The study focuses on the development and detailed analysis of Mg–3Ca alloy foams, uniquely enhanced by ultrafine MgAl2O4 (spinel) particles. This innovative research outlines a novel methodology for improving the mechanical properties of magnesium foams, providing unparalleled advantages for a multitude of industrial applications.

Abstract

The present work reports the synthesis and mechanical behaviour studies of Mg–3Ca alloy foams stabilized by ultrafine MgAl 2 O 4 (spinel) particles. The MgAl 2 O 4 particles were created in-situ in the Mg–3Ca alloy melt through the reaction of Mg, Al and O. Foaming was done by adding dolomite (CaMg(CO 3 ) 2 ) as a blowing agent in the melt. The foaming behaviour was studied for different MgAl 2 O 4 content in Mg–3Ca and holding times (10 and 15 min). The study reveals that the presence of MgAl 2 O 4 significantly influences the foaming behaviour of Mg–3Ca alloy resulting in equiaxed cell structure, uniform cell size distribution, and higher expansion in comparison to the Mg–3Ca alloy foam, which contains only MgO and CaO. An in-depth phase and microstructural analysis were performed to investigate the particles present in the gas-solid interface of the foam that contribute to foam stabilization. The quasi-static compression studies of foams exhibited better compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3) in comparison to the Mg foams reported in the literature. The ductility of the Mg foams was also measured and compared with that of existing aluminium foams.

Research Highlights:-

- Innovative Synthesis: The MgAl2O4 particles are synthesized in situ within the Mg–3Ca alloy melt via a controlled reaction involving Mg, Al, and O. This process ensures the uniform dispersion of spinel particles, which is critical for the foam’s structural integrity and performance.

- Foaming Process: By employing dolomite (CaMg(CO3)2) as a blowing agent, the research team meticulously explored the foaming behaviour under various MgAl2O4 contents and holding times (10 and 15 min). The findings highlight a marked improvement in foam expansion and stability.

- Structural and Mechanical Analysis: Through comprehensive phase and microstructural analyses, the pivotal role of MgAl2O4 particles at the gas-solid interface in stabilizing the foam structure was uncovered. Quasi-static compression tests revealed outstanding compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3), surpassing existing benchmarks for magnesium foams.

Key Properties and Applications:-

- Low Density & High Strength-to-Weight Ratio: The Mg–3Ca alloy foams showcase an optimal balance of low density and high mechanical strength, rendering them ideal for lightweight structural applications.

- Enhanced Energy Absorption: Their unique cellular structure provides superior energy absorption capabilities, suitable for impact and crash-resistant applications.

- Biocompatibility: Owing to magnesium’s biocompatibility, these foams are highly promising for biomedical applications, including bone implants and scaffolds for tissue engineering.

- Thermal Conductivity & Corrosion Resistance: Additionally, these foams exhibit advantageous thermal and corrosion-resistant properties, broadening their applicability across various environmental conditions.

Transformative Impact Across Industries:-

- Aerospace and Automotive: The significant weight reduction capabilities, coupled with uncompromised strength, position the Mg–3Ca alloy foams as revolutionary materials for component design in the aerospace and automotive sectors.

- Biomedical: Their biocompatible nature and structural characteristics make these foams an excellent option for medical implants and scaffolds, poised to improve patient outcomes in orthopaedics and tissue engineering significantly.

- Energy and Beyond: From thermal management solutions in renewable energy systems to applications in sports equipment, the potential uses for these magnesium foams are extensive and diverse, heralding a new chapter in material science.

This groundbreaking research not only advances the field of magnesium foam technology but also paves the way for new possibilities in lightweight, high-performance materials across various industries. The team is dedicated to further exploring the capabilities of these innovative materials and eagerly anticipates partnering with industry stakeholders to transition these advancements from the laboratory to commercial applications.

Continue reading → - SRM AP and TITAN COMPANY LIMITED Jointly Filed an Industrial Patent February 28, 2024

SRM University-AP and TITAN COMPANY LIMITED, a leading jewellery brand in India, have collaborated to engineer novel jewellery products using advanced materials and technologies. The joint research project, led by HOD Prof. G S Vinod Kumar and Ph.D. Scholar Dipak Nandkumar Bhosale, Department of Mechanical Engineering, has resulted in a new method of manufacturing foamed gold alloy that is lighter, stronger, and more durable than conventional gold jewellery.

SRM University-AP and TITAN COMPANY LIMITED, a leading jewellery brand in India, have collaborated to engineer novel jewellery products using advanced materials and technologies. The joint research project, led by HOD Prof. G S Vinod Kumar and Ph.D. Scholar Dipak Nandkumar Bhosale, Department of Mechanical Engineering, has resulted in a new method of manufacturing foamed gold alloy that is lighter, stronger, and more durable than conventional gold jewellery.A joint patent between SRM University-AP and TITAN COMPANY LIMITED has been filed for this innovative method of manufacturing foamed gold alloys. The jewellery products made from this material are currently available in TITAN showrooms under the brand name TANISHQ. The customers can enjoy the benefits of wearing lightweight and high-strength jewellery, which also has a high aesthetic appeal and value.

The collaboration between SRM University-AP and TITAN COMPANY LIMITED exemplifies how academia and industry can work together to create novel and useful products for society. The joint research project also provides an opportunity for the students and faculty of SRM University-AP to gain exposure and experience in the field of jewellery engineering and design and to contribute to advancing science and technology.

Abstract

The current innovation introduces a method for producing foamed gold alloy utilising a liquid metallurgical approach. Gas-releasing agents such as hydrides and carbonates are employed in the manufacturing process. Both 18K and 22K alloys are subjected to foaming in this invention. The resulting foams are stabilised by oxides generated in-situ as well as oxides added externally. These foamed gold alloys exhibit ultra-lower density. The foaming process is successfully executed using both interrupted and uninterrupted methods. These foamed gold alloys find applications in various fields including Jewellery and medical implants.

The title of patent in the citation format

“G. S. Vinod Kumar, Dipak Nandkumar Bhosale. A METHOD OF MANUFACTURING A FOAMED GOLD ALLOY. Indian Patent application number 202341059195 filed Sep 04, 2023”

Patent Application number

202341059195

Inventors

1. G. S. Vinod Kumar 2. Dipak Nandkumar Bhosale

Continue reading →