SRM University-AP Honoured Faculty for their Exemplary Excellence in the Field of Education

SRM University-AP, renowned for its commitment to academic excellence and holistic development, celebrated Teachers’ Day jointly organised by the Directorate of Human Resources & Development and the Directorate of Student Affairs with a heartful tribute to its dedicated faculty members. The event was a testament to the profound impact that teachers have on their student’s lives, shaping not only their academic journeys but also their personal and professional growth.

SRM University-AP, renowned for its commitment to academic excellence and holistic development, celebrated Teachers’ Day jointly organised by the Directorate of Human Resources & Development and the Directorate of Student Affairs with a heartful tribute to its dedicated faculty members. The event was a testament to the profound impact that teachers have on their student’s lives, shaping not only their academic journeys but also their personal and professional growth.

The event was celebrated in the presence of Prof. V S Rao, Advisor; Dr R Premkumar, Registrar, SRM University-AP; Deans; directors; faculty members; and students. It was a collaborative effort by students and staff, who joined hands to pay respectful tribute to the faculty’s exemplary service. The Chief Guest for the event, Prof Devang V Khakhar, Former Director of IIT Bombay, graced the occasion virtually.

During the occasion, Prof V S Rao, Advisor to SRM University-AP, added his words of appreciation, stating, “Teachers are the architects of tomorrow’s world. Their dedication, passion, and commitment inspire and empower the students to reach their full potential. Our faculty members are transitioning from traditional teaching roles to becoming mentors and facilitators.”

In his speech, Chief Guest Prof. Devang V Khakhar underscored the pivotal role of faculty in a university’s success. He stated, “The strength of an academic institution lies in its teachers. They shape the future by enhancing students’ learning capabilities and skills. Indeed, teachers are the true pillars of any academic institution.”

The event also marked the announcement of the Outstanding Faculty Awards, honouring Dr Sunil Chinnadurai, Associate Professor, Department of ECE; Dr Lakshmi Sirisha Maganti, Assistant Professor, Department of Mechanical Engineering; Dr Karthikeyan E, Assistant Professor, Department of ECE; Dr Mahesh Kumar M, Assistant Professor, Department of CSE; Dr Satish Anamalamudi, Associate Professor, Department of CSE; Dr Sabyasachi Chakrabortty, Associate Professor, Department of Chemistry; Dr Rajapandiyan Panneerselvam, Assistant Professor, Department of Chemistry; Dr Vimal Babu – Associate professor, Department of Management; Dr Lakshmana Rao Ayyangari, Associate professor, Department of Commerce for their exceptional contributions to their respective departments. Dr Sutharsan Govindarajan, Assistant Professor in the Department of Biological Sciences, was bestowed with the “Prof. V S Rao Foundation – Prof. HP Tiwari Best Faculty Award“.

The awardees expressed their gratitude to the university and students in their acceptance speeches.

The ceremony also recognised the dedication of faculty members with the Five-Year Services Award. The celebration was moderated by Prof. Sheela Singh, Associate Director of Faculty Affairs, who provided insightful commentary and ensured a smooth flow of events. The celebration concluded with a series of captivating performances by students, showcasing their talents and appreciation for their teachers. The Students Council presented the token of gifts to select adorable teachers. The event was a memorable occasion that highlighted the strong bond between students and faculty at SRM University-AP.

- Published in Departmental News, News, student affairs news

SRM AP’s Hatchlab Research Centre Selected as Implementation Agency for GENESIS Scheme

The Directorate of Entrepreneurship and Innovation is thrilled to announce that the Hatchlab Research Centre (HRC), the Technology Business Incubator at SRM University-AP, has been chosen as the Implementation Agency for the “Gen-Next Support for Innovative Startups (GENESIS)” initiative. This decision, made by the Ministry of Electronics & Information Technology (MeitY), Government of India, marks a significant milestone for HRC and highlights its commitment to fostering innovation and entrepreneurship.

The Directorate of Entrepreneurship and Innovation is thrilled to announce that the Hatchlab Research Centre (HRC), the Technology Business Incubator at SRM University-AP, has been chosen as the Implementation Agency for the “Gen-Next Support for Innovative Startups (GENESIS)” initiative. This decision, made by the Ministry of Electronics & Information Technology (MeitY), Government of India, marks a significant milestone for HRC and highlights its commitment to fostering innovation and entrepreneurship.

The GENESIS scheme emerges as a strategic umbrella initiative by MeitY aimed at nurturing and supporting startup ecosystems in Tier II and Tier III cities across India. HRC is among the 50 selected implementation agencies tasked with facilitating this vision, backed by a total budgetary allocation of ₹490 crores. This funding will be instrumental in providing vital resources and infrastructure for startups, ensuring they have the necessary support to thrive in a competitive landscape.

Prof. Sidharth Shankar Tripathy, Director of Entrepreneurship & Innovation of SRM AP, said, ” This announcement is a tribute to the soaring entrepreneurial spirit that is visible among the students, faculty and even the staff of our young entrepreneurial university. What makes this achievement even more special is that it was announced at an appropriate juncture time when SRM University-AP had declared the academic year 2023-24 as the “Year of Entrepreneurship & Innovation.With this new responsibility, we look forward to contributing to the success of startups and innovators across India!”

The HRC’s selection comes at a fortuitous time, as SRM University-AP has declared the 2023-24 academic year to be the “Year of Entrepreneurship & Innovation.” This initiative aims to foster a culture of creativity and entrepreneurial spirit among students, providing them with the tools and support needed to transform their ideas into viable business ventures.

The GENESIS scheme is designed to enhance the startup ecosystem in smaller cities, enabling entrepreneurs outside of metropolitan areas to access essential services, mentorship, and funding opportunities. By selecting HRC as an implementation partner, MeitY acknowledges the centre’s potential to drive impactful change and support innovative startups in the region.

As HRC embarks on this new journey, it promises to create a robust framework that encourages collaboration, knowledge sharing, and the development of sustainable business models among emerging entrepreneurs. The centre will facilitate various programs, workshops, and resources designed to equip startups with the skills, network, and funding requisite for success.

With this prestigious recognition, SRM University-AP’s Hatchlab Research Centre is poised to play a pivotal role in transforming the entrepreneurial landscape, paving the way for a more inclusive and diverse startup ecosystem across the nation.

- Published in Departmental News, IDEA Events, IDEA NEWS, Innovation, News

From Concept to Reality: The Promising Future of AlN-GDC-HEMT in Electronics

The Department of Electronics and Communication Engineering, SRM University-AP, is pleased to announce that Assistant Professor Dr Durga Prakash has published a noteworthy research paper titled “A Novel LG=40 nm AlN-GDC-HEMT on SiC Wafer with fT/IDS,peak of 400 GHz/3.18 mA/mm for Future RF Power Amplifiers.” This accomplishment reflects Dr Durga Prakash’s expertise and dedication to advancing research in the field and further enriching the academic contributions of the varsity.

Abstract:

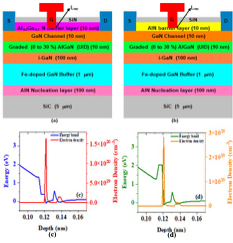

This study presents the initial RF/DC performance of innovative AlN/GaN/Graded-AlGaN/GaN double-channel HEMT (AlN-GDC-HEMT) on SiC wafer. Traditional AlGaN/GaN/Graded-AlGaN/GaN double-channel HEMTs (AlGaN-GDC-HEMT) and the AlN-GDC-HEMT are compared. Both devices form two quantum wells, resulting in prominent double peaks in transconductance and cut-off frequency graphs, demonstrating efficient inter-channel communication. AlN-GDC-HEMT and AlGaN-GDC-HEMT are compared based on gate recess length (LR) and top barrier thickness. Gate lengths (LG) are also used to study HEMT scaling. Additionally, gate engineering and lateral scaling affect both devices’ DC/RF behaviour. Based on rigorous comparison investigation, the AlN-GDC-HEMT outperforms the AlGaN-GDC-HEMT due to its higher polarization (spontaneous) density and larger bandgap. The optimized AlN-GDC-HEMT with LG = 40 nm, LGS = 250 nm, and LGD = 400 nm has high performance, with transconductance (GM) values of 203.1 and 787.5 mS/mm at two peaks, IDS_peak of 1.97 A/mm, IDS_sat of 3.18 A/mm, and the highest fT of 285.1 and 416.8 GHz from the left and right peaks First-stage results suggest AlN-GDC-HEMTs could be used in future RF power amplifiers.

Practical & Social Implications of the Research:

It can be concluded that the AlN-GDC-HEMT that has been proposed is extremely promising, as it possesses remarkable performance and is appealing for power microwave GaN-based HEMT production. This highlights the fact that it is suitable for a broad variety of high-performance applications.

Collaborations:

Department of ECE, Faculty of Science and Technology (IcfaiTech), ICFAI Foundation for Higher Education Hyderabad, Hyderabad-501203, India.

Future Research Plans:

Novel semiconductor device development

- Published in Departmental News, ECE NEWS, News, Research News

Dr Barman Decodes the Mysteries of the Universe

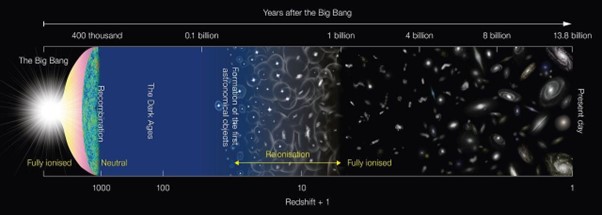

Ever wondered how the universe came into existence? The component with which matter and antimatter were formed? Dr Basabendu Barman, Assistant Professor at the Department of Physics, in his research paper, titled- Leptogenesis, Primordial Gravitational Waves, and PBH-induced Reheating delves into the truth of the formation of matter. Read this exciting paper featured in Physics Review D to learn more!

Abstract:

We explore the possibility of producing the observed matter-antimatter asymmetry of the Universe uniquely from the evaporation of primordial black holes (PBH) that are formed in an inflaton-dominated background. We show it is possible to obtain the desired baryon asymmetry via vanilla leptogenesis from evaporating PBHs of initial mass around 10g. We find that the allowed parameter space is heavily dependent on the shape of the inflaton potential during reheating, the energy density of PBHs, and the nature of the coupling between the inflaton and the Standard Model (SM). To complete the minimal gravitational framework, we also include in our analysis the gravitational leptogenesis set-up through inflaton scattering via exchange of graviton, which opens up an even larger window for PBH mass, depending on the background equation of state. We finally illustrate that such gravitational leptogenesis scenarios can be tested with upcoming gravitational wave (GW) detectors, courtesy of the blue-tilted primordial GW with inflationary origin, thus paving a way to probe a PBH-induced reheating together with leptogenesis.

Practical Implementations & Social Impact:

The first implication lies in the realm of intellect. The question, “Why is the Universe the way it is?” is profoundly significant and has likely intrigued humanity since the dawn of civilization. While technological advancements have allowed us to unravel many of the Universe’s mysteries, we have also come to realize that “what we know is a drop, and what we don’t know is an ocean.” As theoretical particle physicists, our role is to explore this vast ocean of the unknown—a pursuit for which we are rigorously trained. This underscores the vital importance of studying fundamental science. From a practical perspective, our study highlights the crucial role that experiments play in uncovering new knowledge. The synergy between theory and experiment, as we propose, could soon lead to groundbreaking discoveries—or, alternatively, our theory could be disproven if no evidence is found. Either way, it is essential to have advanced experimental facilities and more sensitive detectors to carry out these investigations. This, in turn, calls for increased funding and support for research in the field of high-energy physics.

Collaborations:

India (IIT: Guwahati, Kanpur, Hyderabad; IACS, Kolkata; IOP, Bhubaneswar).

Colombia (Universidad de Antioquia, Universidad de Santiago de Chile).

Abu Dhabi (New York University, Abu Dhabi).

Brazil (IIP, Natal).

Germany (Mainz Institute for Theoretical Physics [MITP], Mainz).

Poland (University of Warsaw).

Spain (Universidad Complutense,Madrid; IFIC, Valencia).

China (T D Lee Institute).

Korea (IBS, Daejeon; KIAS, Seoul; Kyungpook National University, Daegu).

Japan (Hokkaido Univeristy).

France (IJC Lab, Paris).

Sweden (KTH, Stockholm)

US (Washington University, St. Louis; University of Minnesota; Indiana University; University of Pittsburgh, University of Kentucky).

Future Plans:

A closer look into early universe dynamics by performing more involved simulations.Connection between particle physics models and early Universe cosmology.Complementary searches from different experiments in unravelling new physics beyond the Standard Model.

Link: https://journals.aps.org/prd/abstract/10.1103/PhysRevD.110.043528

- Published in Departmental News, News, Research News