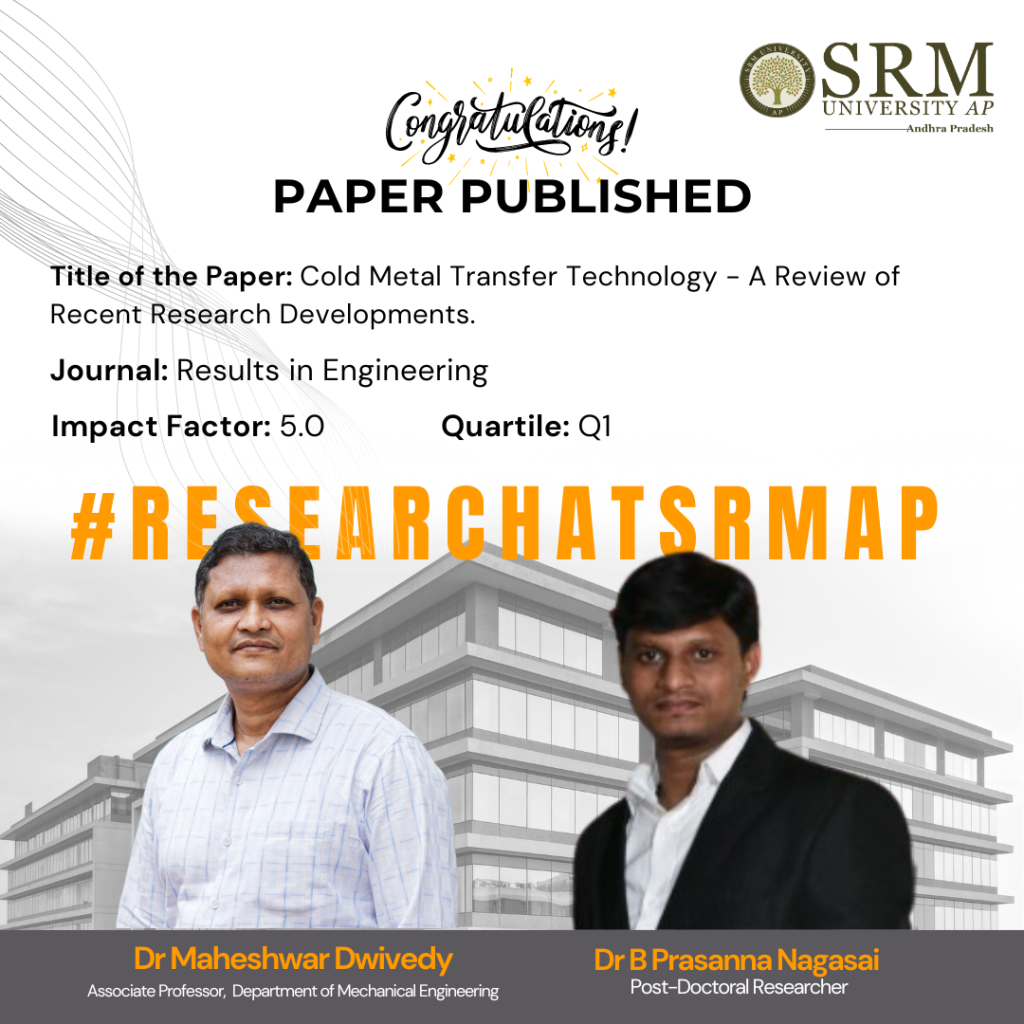

Dr Dwivedy and Dr Nagasai Upgrade CMT Technology

Dr Maheshwar Dwivedy, Associate Dean of Practice School, and Associate Professor, at the Department of Mechanical Engineering, SRM University-AP in collaboration with his post-doctoral scholar, Dr B Prasanna Nagasai, have joined forces to combine artificial intelligence with Cold Metal Transfer (CMT) Technology. Their research paper, “Cold Metal Transfer Technology – A Review of Recent Research Developments,” featured in the Q1 journal, Results in Engineering promises to make a significant impact on automobile, aerospace, oil and gas manufacturing industries, and that’s not all the research will also generate employment opportunities, and empower engineers to deliver enhanced services.

Abstract:

Cold Metal Transfer (CMT) technology has emerged as a promising welding technique, offering numerous advantages such as reduced heat input, minimal spatter, and enhanced control over the welding process. This paper provides a comprehensive review of recent research developments in CMT technology, focusing on its history, variants, recent advancements, and future perspectives. Initially, the paper traces the historical development of CMT welding, highlighting its evolution and the introduction of various CMT variants with distinct characteristics and applications. Recent studies have focused on optimising CMT process parameters to improve weld quality and productivity, leading to advancements in parameter control, arc stability, and wire-feeding mechanisms. Additionally, research has explored the microstructural evolution and mechanical properties of CMT-welded joints for both similar and dissimilar metals, providing insights into material compatibility, joint design, and performance under various conditions. Specific applications such as Laser-CMT hybrid welding, CMT cladding, CMT wire arc additive manufacturing, and CMT welding for repair across various materials are examined, demonstrating the versatility of CMT technology. This review also addresses the challenges and methodologies for defect reduction in CMT welding, along with recommendations for best practices. Furthermore, the paper discusses the integration of artificial intelligence in CMT welding, exploring opportunities for enhanced weld quality, economic, and social implications, and future research directions.

Practical and Social Implications:

The practical implementation of this research on Cold Metal Transfer (CMT) technology can significantly impact various industries, such as automotive, aerospace, oil and gas, and manufacturing. By optimising CMT welding parameters and integrating advanced features like arc length control and waveform modulation, industries can achieve higher weld quality, reduce defects, and enhance productivity. This can lead to more reliable and efficient manufacturing processes, resulting in cost savings and improved product performance. Social implications associated with this research include the potential for increased job opportunities and skill development in the welding and manufacturing sectors. As industries adopt advanced CMT technology, there will be a growing demand for skilled workers trained in these techniques. Additionally, improved welding quality and reduced defects can lead to safer and more durable products, enhancing overall public safety and satisfaction. The integration of artificial intelligence in CMT welding also opens up new avenues for innovation and technological advancements, fostering a culture of continuous improvement and progress in the manufacturing industry.

Collaborations:

Dr V Balasubramanian,

Professor & Director,

Centre for Materials Joining & Research (CEMAJOR)

Annamalai University, Annamalai Nagar-608002, Tamilnadu.

Dr P Snehalatha,

Associate Professor & Head

Department of Mechanical Engineering,

Sri Padmavathi Mahila Visvavidyalam, Tirupati, Andhra Pradesh-517502, India.

Future Research Plans:

The upcoming work will concentrate on creating Functionally Graded Materials (FGMs) through Wire-Arc Additive Manufacturing (WAAM) by merging nickel and stainless steel. The goal of this research is to leverage the distinct properties of each metal to develop components suited for specialised high-performance applications. The primary challenges involve optimizing the interfaces between materials, refining the deposition processes, and ensuring strong structural integrity throughout the manufacturing process.

The link to the article: https://doi.org/10.1016/j.rineng.2024.102423

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

“Nano Jatha”: A Pathway to Nanoscience and Technology

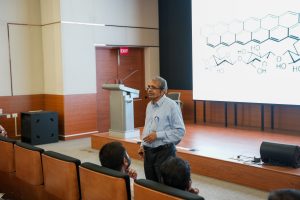

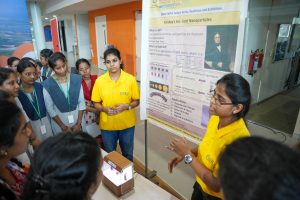

As part of the 13th edition of the Bengaluru India Nano 2024, heralded by Bharat Ratna recipient and renowned chemist Prof. C N R Rao, SRM University-AP hosted “Nano Jatha“, an intensive science outreach programme, catering to educate undergraduate graduates on the emerging trends of nanotechnology, on July 20, 2024. The Nano Jatha programme organised, aimed to raise awareness on nanoscience and technology through technical presentations by expert scientists and a distinctive live experiment demonstration of nano kits focused on showcasing nanoscience ideas.

The event featured two expert talks by eminent dignitaries. Prof. B L V Prasad, Director-Centre for Nano and Soft Matter Sciences (CeNS), Department of Science and Technology, Govt. of India, also serving as the Nodal Officer for organising Nano Jatha events, delivered a session on the introduction to nanoscience and technology. “Nanoscience and technology are often foretold as the technology of the future. This multidimensional technology will revolutionise our understanding of every natural phenomenon and every aspect of human life,” remarked Prof. Prasad in his session.

Prof. C P Rao, Senior Professor at the Department of Chemistry, presented the second expert talk on the applications of nanomaterials. The session delved into the properties of covalent molecules and its assemblage leading to cutting-edge technology. The programme also featured an exhibition were experiments on Gold nanoparticle; Galvanization reaction between metals; Piezoelectric pavement for futuristic applications; Humidity sensors for real-world applications and many more were displayed.

Prof. C V Tomy, Dean-School of Engineering & Sciences and Dr Pardha Saradhi Maram, Head-Department of Chemistry, emphasised that the Nano Jatha exemplified the university’s commitment to hands-on learning in science, specifically nanotechnology.They commented that the Department of Chemistry is dedicated to fostering scientific knowledge and igniting passion for chemistry among students and educators alike and will continue to organise events like Nano Jatha, conferences, workshops, and Faculty Development Programmes to achieve the same.

Over 300 students from 7 regional colleges in Andhra Pradesh participated in the programme, displaying their zeal in the discussions and nano kit demonstrations. The event was well executed benefitting the student community significantly in understanding various emerging fields in science and technology.

- Published in Chemistry-news, Departmental News, News

Faculty and Students Leads to Patent Publication for Intelligent Shelf Management System

In a groundbreaking collaboration, Dr Banee Bandana Das, Assistant Professor in the Department of Computer Science and Engineering, and Dr Saswat Kumar Ram, Assistant Professor in the Department of Electronics and Communication Engineering, have joined forces with Btech-CSE students Mr Rohit Kumar Jupalle, Mr Dinesh Sai Sandeep Desu, and Mr Nikhil Kethavath to develop and patent an innovative invention.,” The team’s invention, titled “A SYSTEM FOR VISION-BASED INTELLIGENT SHELF MANAGEMENT SYSTEM AND A METHOD THEREOF,” has been officially filed and published with Application Number 202441039394 in the Patent Office Journal. This invention showcases the academic excellence and collaborative spirit within the institution, as faculty members and students work together to push the boundaries of technology and create solutions with real-world impact.

In a groundbreaking collaboration, Dr Banee Bandana Das, Assistant Professor in the Department of Computer Science and Engineering, and Dr Saswat Kumar Ram, Assistant Professor in the Department of Electronics and Communication Engineering, have joined forces with Btech-CSE students Mr Rohit Kumar Jupalle, Mr Dinesh Sai Sandeep Desu, and Mr Nikhil Kethavath to develop and patent an innovative invention.,” The team’s invention, titled “A SYSTEM FOR VISION-BASED INTELLIGENT SHELF MANAGEMENT SYSTEM AND A METHOD THEREOF,” has been officially filed and published with Application Number 202441039394 in the Patent Office Journal. This invention showcases the academic excellence and collaborative spirit within the institution, as faculty members and students work together to push the boundaries of technology and create solutions with real-world impact.

This significant achievement not only highlights the creativity and dedication of the individuals involved but also underscores the institution’s commitment to fostering a culture of innovation and research. The publication of this invention paves the way for further exploration and development in the field of intelligent shelf management systems, demonstrating the potential for transformative contributions to the industry.

Abstract

This research offers the best solution to improve the business in the retail realm, maintaining On- Shelf Availability (OSA) is vital for customer satisfaction and profitability. Traditional OSA methods face accuracy challenges, prompting a shift to deep learning models like YOLO and CNN. However, data quality remains a hurdle. This research introduces OSA, a novel semi-supervised approach merging ’semi-supervised learning’ and ’on-shelf availability’ with YOLO. It reduces human effort and computation time, focusing on efficient empty-shelf detection. Implementing a Vision-Based Intelligent Shelf Management System empowers retailers with real-time insights, revolutionizing decision-making. The model is optimized for diverse devices and provides practical solutions for efficient retail operations. Balancing model complexity, size, latency, and accuracy, the research paves the way for an advanced, data-driven shelf management approach, contributing to improved shopping experiences and business profitability

Practical Implementation and the Social Implications Associated

1. The present invention is a time-saving method in maintaining the stocks.

2. The use Vision-Based Intelligent Shelf-Management System provide a well alternative in reducing the labor efforts.

3. The system will help in terms of self-management system using machine learning techniques to optimize restocking decisions.

The present invention can be used in shopping malls and business areas for enhancing customer experiences and business and few application areas are:

• Smart City and smart Village

This technique and system can reduce the human efforts in identifying vacant slots for items in business areas and provides necessary inputs to fill the same within a time frame.

• Automobile Industry

The system can be easily integrated with the showrooms to identify the empty spaces and inform to get it fill with products.

Collaborations

SRM AP Faculties and UROP Students

Future research plan

In the future, different deep learning and machine learning methods can be merged to explore better performance in identifying overlapping objects.

- Published in CSE NEWS, Departmental News, ECE NEWS, News, Research News

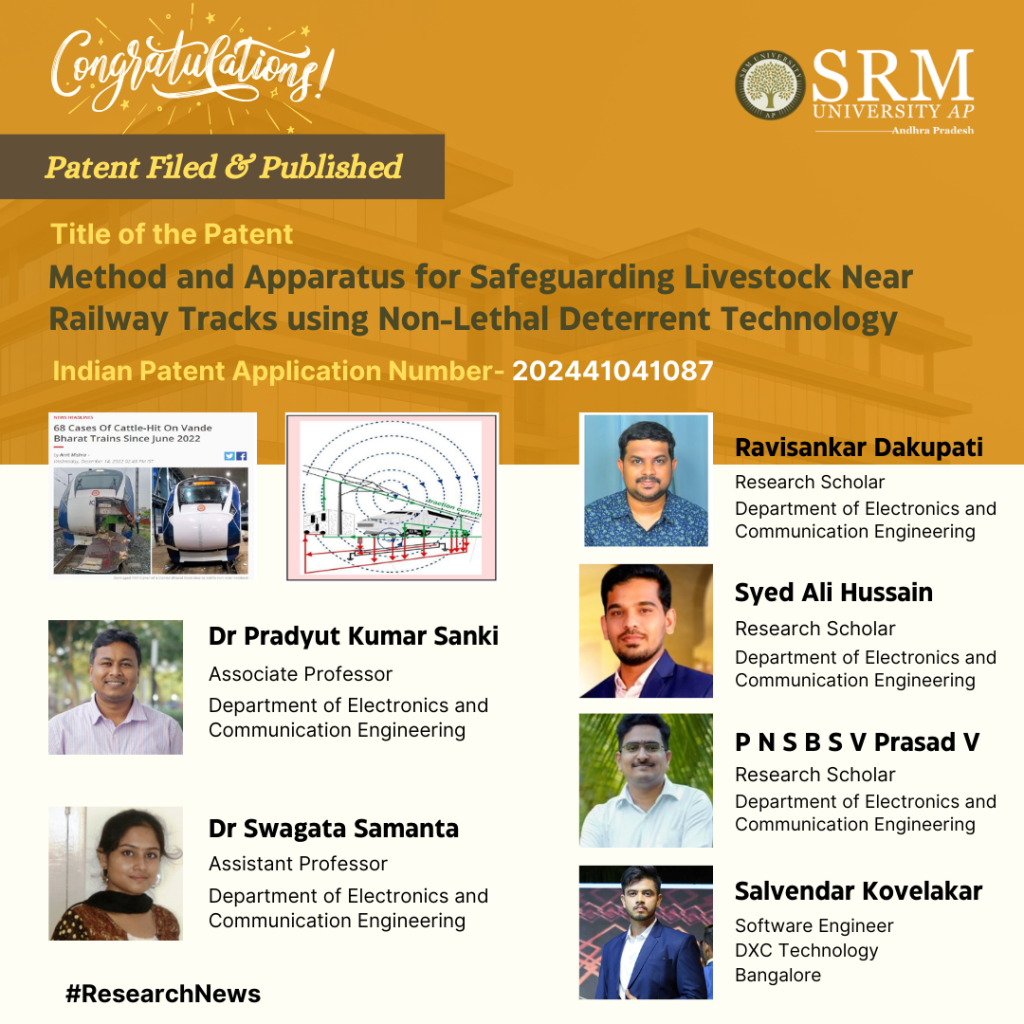

Revolutionising Cattle Safety

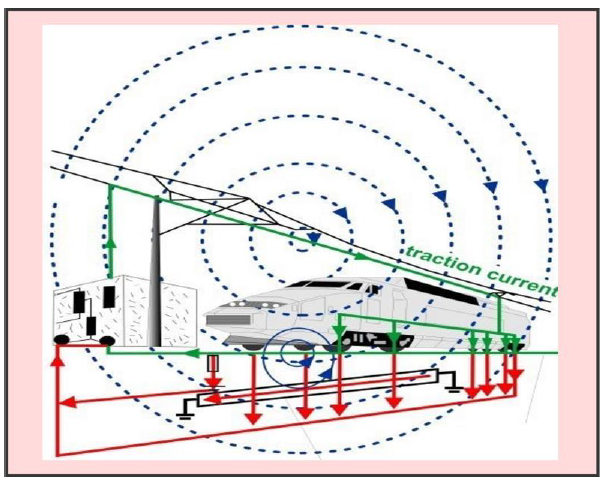

The Department of Electrical and Communication Engineering at SRM University-AP is delighted to announce the publication of a patent by its faculty, including Associate Professor Dr Pradyut Kumar Sanki and Assistant Professor Dr Swagata Samanta, along with research scholars Ravisankar Dakupati, Syed Ali Hussain, and P N S B S V Prasad V. The patent, titled “Method and Apparatus for Safeguarding Livestock Near Railway Tracks using Non-Lethal Deterrent Technology,” has introduced a groundbreaking solution that helps prevent accidents of wandering cattle. This innovative technology promises to protect livestock and minimise economic losses for cattle owners while championing the advancement of technology in countries like India.

Abstract:

Nowadays we have been hearing that Vandebharat express train hits cow, causing damage to both railways and cattle owners. We need to find a solution to this problem. These issues shouldn’t be hurdle for the growth of technology for developing countries like india. The technology we are going to use is a belt is worn by a cow. When the cow tries to cross near railway track it receives a Non-Lethal shock, makes the cow to scare and move back. All this circuit is operated with 7.4V DC

Practical implementation:

The practical implementation of the Anti-Track Cattle Band involves equipping cows with the device to prevent accidents near railway tracks. By detecting magnetic fields and delivering non-lethal shocks, the device ensures the safety of both the cattle and the railway infrastructure. This implementation can significantly reduce the risk of collisions and protect valuable livestock.

From a social perspective, the invention has several implications. It addresses the safety concerns of both animals and humans by preventing accidents and minimizing potential harm. By safeguarding livestock near railway tracks, the technology contributes to animal welfare and reduces economic losses for cattle owners. Additionally, the device promotes a more humane and proactive approach to mitigating risks associated with animal-human interactions in railway environments.

Collaborations:

The research on the Anti-Track Cattle Band involved collaboration among a team of inventors with diverse expertise:

Ravisankar Dakupati – Research Scholar at SRM University-AP

Salvendar Kovelakar – Software Engineer at DXC Technology, Bangalore

Syed Ali Hussain – Research Scholar at SRM University-AP

P N S B S V Prasad V – Research Scholar at SRM University-AP

Dr Pradyut Kumar Sanki – Associate Professor at SRM University-AP

Dr Swagata Samanta – Assistant Professor at SRM University-AP

This collaborative effort brought together individuals with backgrounds in research, software engineering, and academia to develop and implement the innovative Anti-Track Cattle Band technology.

Future Research Plans:

In future research for patent publication regarding “Apparatus and Method for Railway Livestock Protection,” the focus will likely be on enhancing sensor technology to detect animals more accurately over longer distances and in various conditions. This could involve integrating artificial intelligence and machine learning for improved detection and reducing false alarms. Additionally, there may be efforts to develop systems for remote monitoring and control, enabling real-time adjustments from a central location. Adaptability to different environments, collaboration for standardized protocols, cost-effectiveness, and assessing environmental impacts will also be key areas of interest. Overall, future research aims to create more effective, efficient, and sustainable solutions for protecting livestock around railway tracks

- Published in Departmental News, ECE NEWS, News, Research News