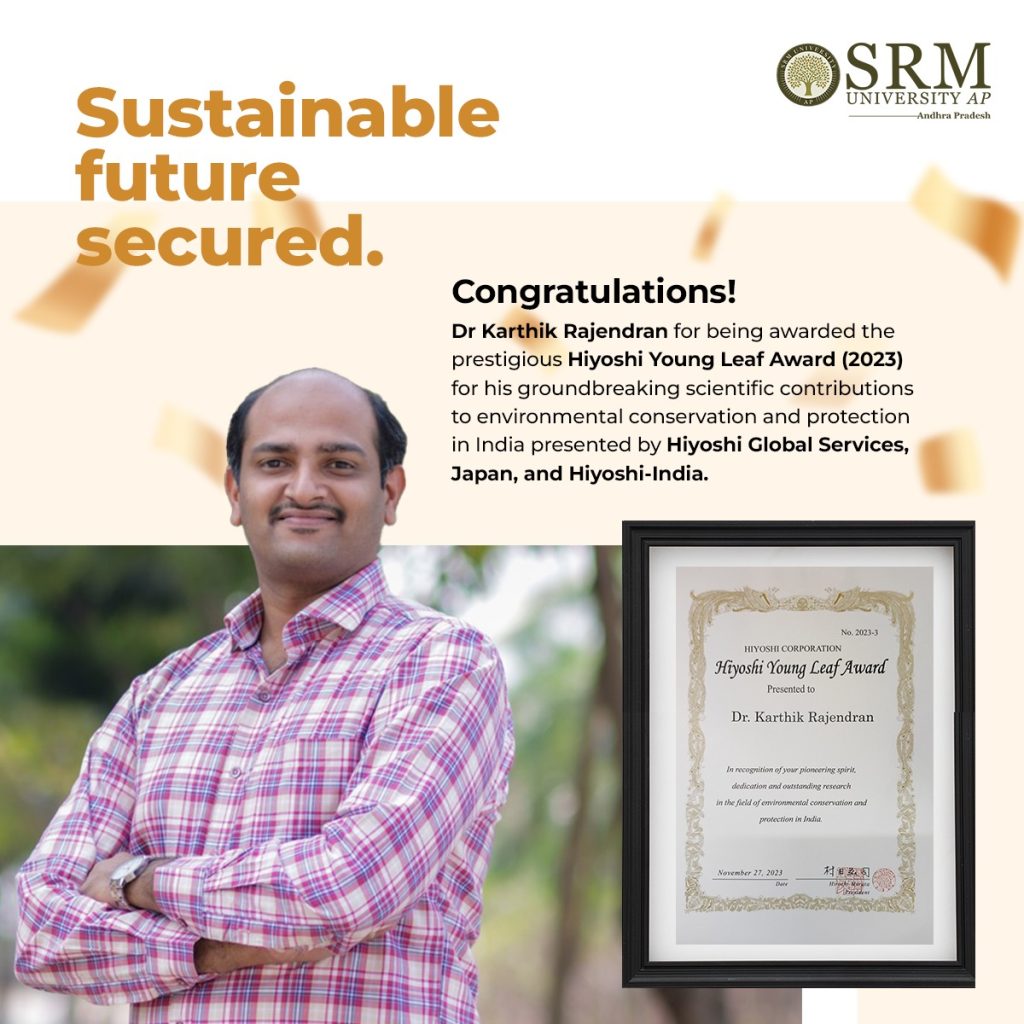

Dr Karthik Rajendran Receives Hiyoshi Young Leaf Award

A proud moment for SRM University-AP as Dr Karthik Rajendran, Associate Professor in the Department of Environmental Science and Engineering, receives the prestigious Hiyoshi Young Leaf Award.

The Hiyoshi Young Leaf Award recognises novel, innovative, and outstanding scientific research and application in the field of environmental conservation and protection in India. Dr Rajendran’s dedication to research, innovative approaches, and impact on the academic community have earned him this esteemed accolade.

“We extend our heartfelt congratulations to Dr Karthik Rajendran for this well-deserved recognition,” said Prof. Manoj K Arora, Vice Chancellor, SRM University-AP. “His exemplary work reflects the varsity’s commitment to fostering excellence in the field of Environmental Science and Engineering.”

“It is a great honour to be receiving the Hyoshi Young Leaf Award, it motivates me further to work harder and with greater passion, I would like to thank Hiyoshi Corporation for presenting me with this award,” said Dr Karthik Rajendran.

Dr Rajendran has received several awards in the past for his remarkable contributions to the field of environmental science and engineering. He has been recognised as one of the top 2% of scientists by Stanford University and has also been honoured with the Young Scientist Award among others. Apart from his research, Dr Rajendran is also dedicated to educating the next generation of environmental scientists and engineers, thereby playing a crucial role in shaping future leaders in the field.

SRM University-AP celebrates this milestone in Dr Rajendran’s career and looks forward to continued excellence in his contributions to environmental science.

- Published in ENVS News, Faculty Achievements, News

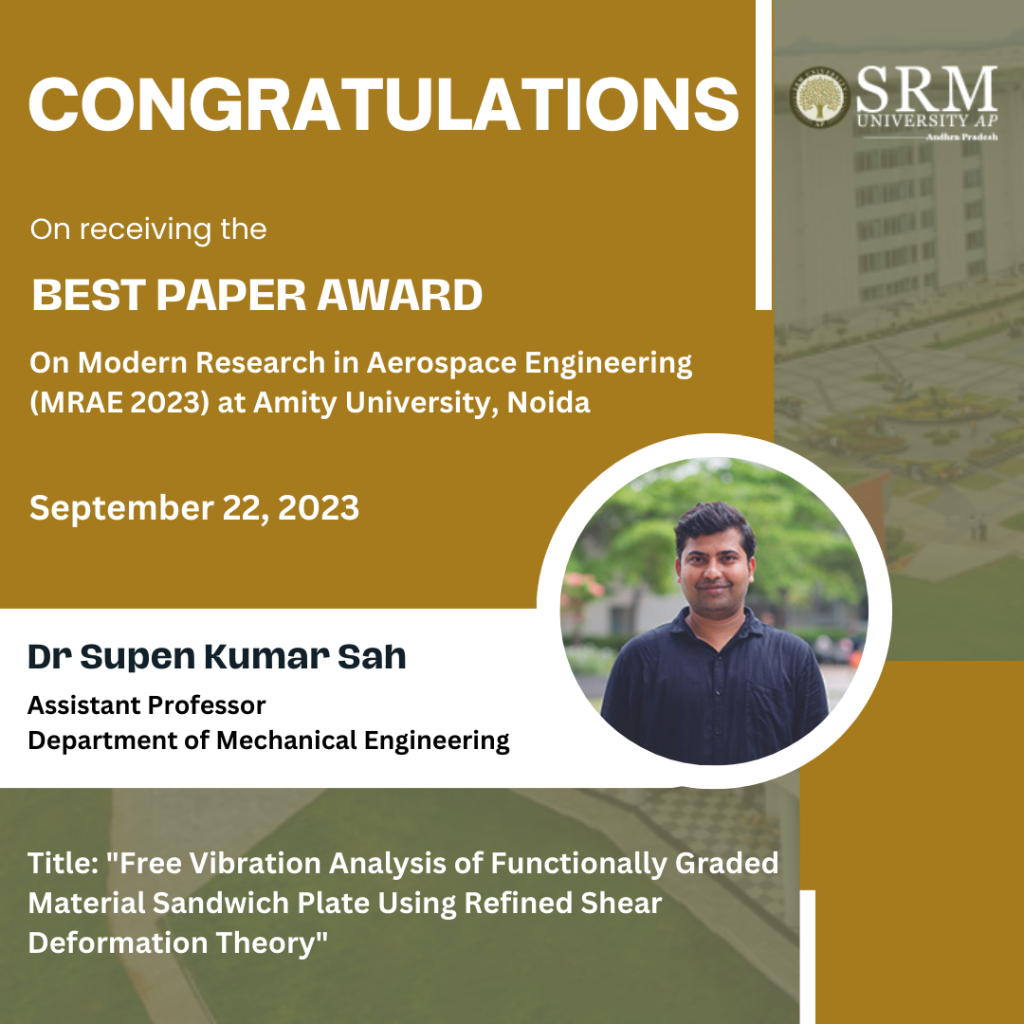

Best Paper Award: Accorded to Dr Supen Kumar at MRAE 2023

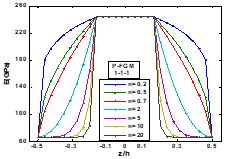

The Department of Mechanical Engineering is delighted to share that Dr Supen Kumar Sah, Assistant Professor, Department of Mechanical Engineering, has received the best paper award for his paper titled “Free Vibration Analysis of Functionally Graded Material Sandwich Plate Using Refined Shear Deformation Theory” in the 2nd International Conference on Modern Research in Aerospace Engineering (MRAE 2023). Dr Supen collaborated with Saloni Malviya of VIT, Bhopal, for the research paper. The paper explores the intricate dynamics of functionally graded material sandwich plates, employing a refined deformation theory. Dr Sah’s exceptional work has not only contributed to the scientific community but has also demonstrated his dedication and passion for advancing knowledge in the field of materials science and engineering.

Abstract

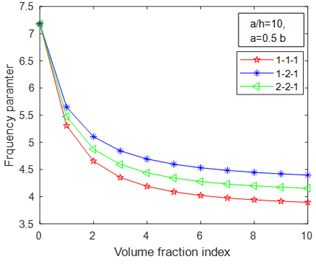

In the present study, free vibration analysis of a functionally graded material sandwich plate has been carried out using refined shear deformation theory. The shear correction factor is not needed since the parabolic variation of shear strain through the thickness is in such a way that shear stresses vanish on the plate surfaces. Hamilton’s principle is used for the derivation of the equation of motion for the theory. Additionally, Navier’s solution is used to obtain the eigenvalue equation for the sandwich plate. The three variants of sandwich plate are chosen for the analysis. To carry out the free vibration analysis three different types of FGM sandwich plate models namely 1-1-1, 1-2-1, and 2-2-1 have been considered. A power law defines the volume fraction index and the material properties of the individual layers of the sandwich plate. Lastly, the impact of parameters such as volume fraction, aspect ratio, and length-to-width ratio on frequency parameters is investigated.

Future Research Plans

• Modelling and Analysis of porous uni and multi-directional Functionally Graded Material (FGM) plates to obtain the impact of porosity distributions over structural responses.

• Analytical and finite Element Solutions for static and dynamic response of FGM sandwich plates employing non-polynomial shear deformation theories under elastic foundation.

- Published in Departmental News, Faculty Achievements, Mechanical Engineering NEWS, News, Research News

SRM AP Educators Accredited with Cambridge Certification

SRM University-AP educators, Dr Balaguruprasad Narayanan and Dr Anupama Ghattu from the Teaching and Learning Centre are now accredited facilitators under The Cambridge Assessment International Education Program Leaders. The Duo have earned their specialisations in the Teaching and Learning Program & Teaching with Digital Technologies Program respectively.

The certification will enable the educators to provide the faculty and students with specialised competency in teaching and learning mechanisms, it will also facilitate student learning experiences. Following this accreditation, the programme leaders through TLC are planning to guide SRM University-AP faculty members for International Cambridge Certification in one of the above-mentioned programmes of their choice.

Congratulations to Dr Ghattu and Dr Narayanan!

- Published in Departmental News, Faculty Achievements, News, TLC

Assistant Professor Certified as Remote Pilot Instructor under DGCA

The world of technology is constantly evolving, and the aviation industry is no exception. From being operated exclusively by humans, aircraft systems have now advanced into Unmanned Aircraft Systems (UAS). To stay current in this ever-changing landscape, it’s crucial to update and upscale one’s skills.

Dr Raviteja KVNS, Assistant Professor at the Department of Civil Engineering, has successfully completed his rigorous training programme at the highly acclaimed Indira Gandhi Rashtriya Uran Akademi (IGRUA) and is now certified as Remote Pilot Instructor by The Director General of Civil Aviation (DGCA). With his newfound expertise on unmanned aerial vehicles, Dr KNVS is now poised to offer his invaluable guidance and support to aspiring drone pilots.

We extend our sincere congratulations to him on this outstanding achievement.

- Published in CIVIL NEWS, Faculty Achievements, News

First patent granted to SRM University-AP

Title of the Patent: A Process for Preparing Magnesium Foams

Patent applicant: SRM University-AP, Andhra Pradesh

Patent Application number: 202041001715

Date of Filing: 14/01/2020

Date of Publication: 24/01/2020

Date of Grant: 16/08/2021

Prof G S Vinod Kumar and his PhD Scholar Mr Dipak Nandkumar Bhosale from the Department of Mechanical Engineering has brought the first granted patent to SRM University-AP. The patent titled “A Process for Preparing Magnesium Foams” is on the novel processing of Magnesium alloy foams via molten metal route. Metal foams are the class of novel ultra-lightweight and high strength materials used for engineering structures. Under the light-alloy category, Magnesium alloys possess greater challenges to foam and the inventors Mr Dipak Bhosale, PhD scholar and Prof Vinod Kumar (PhD supervisor) of Dept. of Mechanical Engineering have come up with a novel process to foam Magnesium alloy effectively. The patent was filed on January 14, 2020, and granted on August 16, 2021. It is indeed commendable that the patent grant is obtained in just 16 months from the date of application.

Prof G S Vinod Kumar and his PhD Scholar Mr Dipak Nandkumar Bhosale from the Department of Mechanical Engineering has brought the first granted patent to SRM University-AP. The patent titled “A Process for Preparing Magnesium Foams” is on the novel processing of Magnesium alloy foams via molten metal route. Metal foams are the class of novel ultra-lightweight and high strength materials used for engineering structures. Under the light-alloy category, Magnesium alloys possess greater challenges to foam and the inventors Mr Dipak Bhosale, PhD scholar and Prof Vinod Kumar (PhD supervisor) of Dept. of Mechanical Engineering have come up with a novel process to foam Magnesium alloy effectively. The patent was filed on January 14, 2020, and granted on August 16, 2021. It is indeed commendable that the patent grant is obtained in just 16 months from the date of application.

Metal foam is a cellular structure consists of solid metal with gas-filled pores. The pores can be sealed (closed-cell foam) or interconnected (open-cell foam). The present patent relates to a process for the preparation of closed-cell Magnesium foams using dolomite [CaMg (CO3)2] as a blowing agent (gas source), through a liquid metal route. The inventors have demonstrated economical and naturally occurring mineral dolomite to be an effective blowing agent for preparing magnesium foams and in-situ formed MgAl2O4 (spinel) particles as the stabilizing agent during stabilization of foams. The Magnesium foams produced by the process of the present disclosure have a good expansion, lower density, uniform pore size distribution and polyhedral pore structure. Through the present process Magnesium foams with 88% porosity 0.20 g/cm3 foam density was obtained. Magnesium foam is an attractive material that exhibits a unique combination of mechanical, physical, thermal, electrical and acoustic properties. It has high strength to weight ratio, good compressive strength and high energy/shock/vibration/sound absorption efficiency. Owing to these properties the magnesium foam finds potential in lightweight structural applications, sound-absorbing, energy and vibration and shock damping application.

C&EN features Dr Anil’s Research on sustainable biofilm

Dr Anil K Suresh’s innovative research has been brought into the limelight by the revered weekly magazine Chemical & Engineering News (C&EN), published by the American Chemical Society. Dr Anil K Suresh, Associate Professor, Department of Biological Sciences, and his team from SRM University-AP recently developed a see-through transparent (with 85% above transmittance) biotemplate which they derived from the fish scale wastes to substitute the extensive usage of eco-unfriendly disposal plastic cuvettes for UV-Visible Spectroscopy measurements in the spectrum of 350-900 nm.

Dr Anil K Suresh’s innovative research has been brought into the limelight by the revered weekly magazine Chemical & Engineering News (C&EN), published by the American Chemical Society. Dr Anil K Suresh, Associate Professor, Department of Biological Sciences, and his team from SRM University-AP recently developed a see-through transparent (with 85% above transmittance) biotemplate which they derived from the fish scale wastes to substitute the extensive usage of eco-unfriendly disposal plastic cuvettes for UV-Visible Spectroscopy measurements in the spectrum of 350-900 nm.

UV-Vis spectroscopy is a versatile analytical tool used to examine the nature of various synthetic, biological and clinical molecules for pharmaceutical and environmental applications. The team members demonstrated the practical on-biotemplate analysis of diverse analytes such as DNA, proteins, nanoparticles, organic dyes, bacteria, BSA assay and dye-degradations. Dr Anil K Suresh owns the copyrights for this pathbreaking invention by being granted an Indian patent. This work was published in the prestigious Journal “Green Chemistry” by the Royal Society of Chemistry. Read the full paper here.

Chemical & Engineering News (C&EN), which is widely known to feature articles of the best professional and technical innovative research work and analysis in the fields of chemistry and chemical engineering, has acknowledged Dr Anil’s research by allowing it little room in their magazine in Volume 99, Issue 36 (Read the news here). C&EN includes information on recent news and research in chemistry and chemical engineering along with career and employment information, business and industry news, government and policy news, funding in these fields, and special reports.

“The magazine is very celebrated among researchers across the world. It is a great honour for my team and me to be featured in the magazine. This news magazine usually picks only top nature cell science publications among thousands, and My team and I are feeling great to be one of them,” said Dr Anil. Dr Anil further said that it would not be possible to carry out such prominent research work in a newly built establishment without the constant support from the management of SRM University-AP, Andhra Pradesh. He has profoundly thanked Dr P Sathyanarayanan, President; Prof V S Rao, Vice-Chancellor; Prof D Narayana Rao, Pro-Vice-Chancellor, for their kind help and cooperation.

The University Management congratulated Dr Anil K Suresh on his achievement. Dr Sathyanarayanan said, “It is indeed a proud moment for the university to be featured on C&EN. I compliment Dr Anil and his team on their tireless work.” “Dr Anil and his team have executed an extraordinary work towards a green environment which should be emphasised in international journals. The Team’s dedication towards their research is commendable,” said Prof V S Rao. Prof D Narayana Rao opined that Dr Anil K Suresh is one of the most talented young biologists in the nation. “I have personally known him for some time being and working with him for a few years. Dr Anil is devoted biologist and pride of the university,” asserted Prof D Narayana Rao.

- Published in Biology News, Faculty Achievements, News, Research News, Students Achievements

Dr Aqsa Agha receives the South Asia Public Health Fellowship

Dr Aqsa Agha, Assistant Professor, the Department of History, has been awarded the South Asia Public Health Fellowship Project by The Institute of Public Health (India) in collaboration with the International Union against Tuberculosis and Lung Disease. As the South Asia Public Health Fellow-India, Dr Agha is expected to conduct research on the ethics of the tobacco industry and submit the report over a period of 8 months, i.e. from December 01, 2021, to July 31, 2022. She has been granted an amount of USD 6660 to carry out the project.

Dr Aqsa Agha, Assistant Professor, the Department of History, has been awarded the South Asia Public Health Fellowship Project by The Institute of Public Health (India) in collaboration with the International Union against Tuberculosis and Lung Disease. As the South Asia Public Health Fellow-India, Dr Agha is expected to conduct research on the ethics of the tobacco industry and submit the report over a period of 8 months, i.e. from December 01, 2021, to July 31, 2022. She has been granted an amount of USD 6660 to carry out the project.

Along with producing a quality case study on India focusing on industry interferences promoting the tobacco epidemic and undermining public policies related to tobacco control, the project entails drafting the regional report on South Asia. It will bring together country-level case studies and implications between December-May, 2022, engaging in the dissemination of the country-level case studies with relevant stakeholders in June-July 2022.

Article 5.3 of the World Health Organization Framework Convention on Tobacco Control (WHO FCTC) acts as a treaty for ratified countries to protect their citizens against the commercial and vested interests of the tobacco industry as per guidelines laid down in the said article. Countries of South Asia, including India, have signed and fully ratified this treaty in the early 2000s. However, the lack of robust national policies and continued influence of the tobacco industry perpetuates the tobacco epidemic, as established in the available literature. Given each country’s mandate to protect the health of its citizens, there is a growing need to understand issues of tobacco industry interferences that undermine public policies meant to protect its population. The South Asian Public Health Fellowship is an initiative to generate knowledge regarding issues of tobacco industry interference not only in India but in other countries of South Asia (i.e., Nepal, Sri Lanka and Bangladesh) to better understand such issues from a regional perspective.

Dr Aqsa Agha holds a PhD in History from the Centre for Historical Studies, JNU. She is also the Project Head of Unnat Bharat Abhiyan at SRM University-AP. Before joining SRM University-AP, Dr Agha was a Consultant with Partners in Change, New Delhi and prepared a report titled “Status of Corporate Responsibility in India, 2020”, focusing on corporate responsibility and ethical business practices. Prior to that, she worked as a Research Officer for National Research Study on Human Trafficking in India at TISS, Mumbai. Before TISS, she worked with the Human Rights Defenders’ Alert- India on human rights violations on the India-Bangladesh border in West Bengal. Along with teaching, she has consulted with organisations, including the Centre for Equity Studies, New Delhi, where she conducted sessions with grassroots activists to effectively observe, analyse and document reality through participatory research. Her broader research interest lies in historical processes and their impact on the social locations of class, caste and gender.

- Published in Faculty Achievements, History Current Happenings, History News, News, Research News

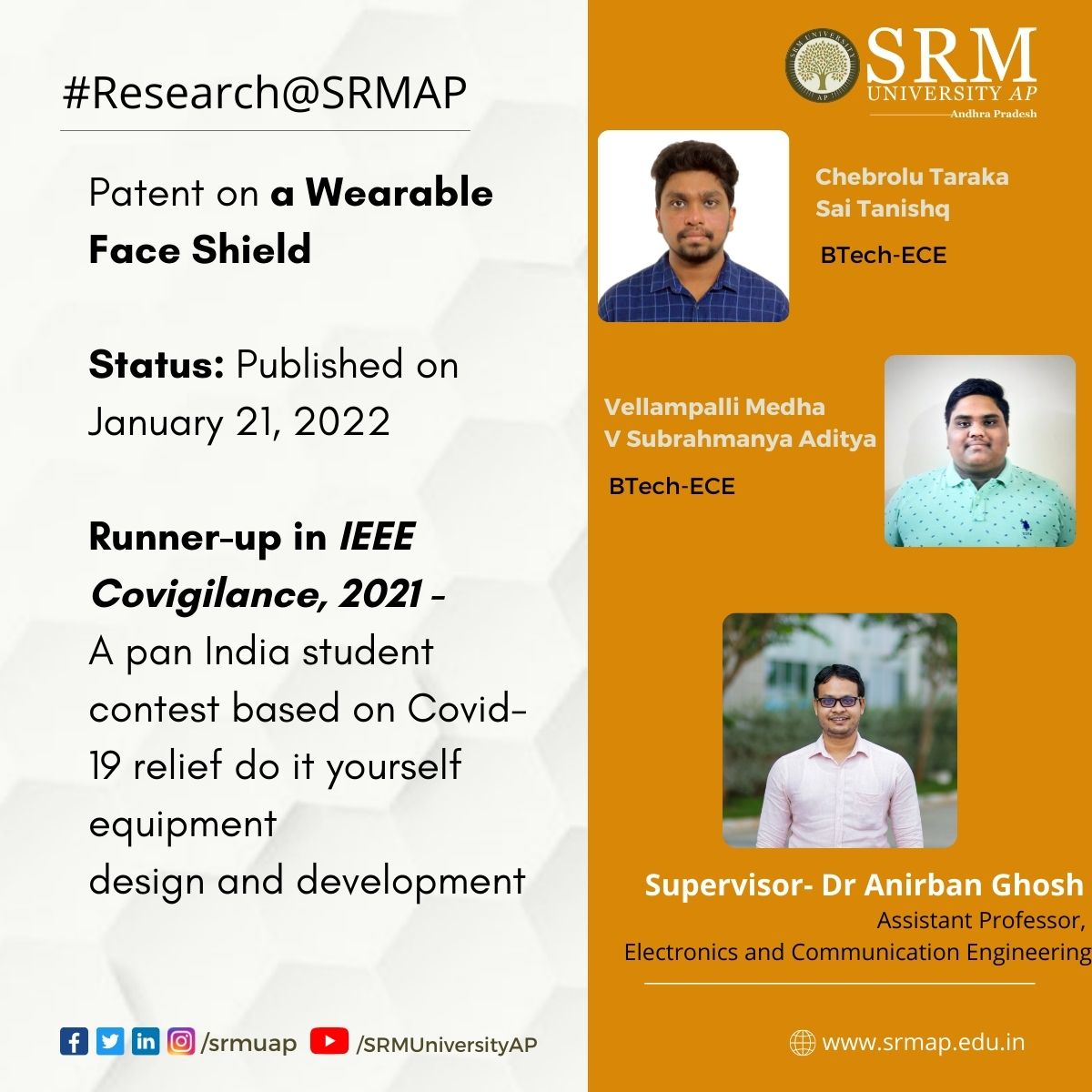

A Wearable Face Shield: Pioneering engineering invention

The Department of Electronics and Communication Engineering is proud to announce the remarkable achievement of the students Chebrolu Taraka Sai Tanishq and Vellampalli Medha V Subrahmanya Aditya. They have designed a wearable face shield and secured the second position in IEEE Covigilance, 2021 – A pan India student contest based on Covid-19 relief do it yourself equipment design and development, under the guidance of Dr Anirban Ghosh, and got a patent published for their prototype developed as part of the competition. The team also participated in the 4th Research Day organized by SRM University-AP and received a gold medal.

The prototype was submitted in the design competition on July 30, 2021, and after 40 days of rigorous brainstorming, component procurement and prototype development, the final model was submitted for evaluation. Based on prototype execution, feasibility of manufacturing and suitability of the model to contain the spread of the pandemic, the team secured second place in the Pan India contest, and it was deemed fit to address the two criteria; innovation challenges like Innovation of homemade masks/shields/PPEs and innovation of a feasible solution to control covid-19 spread while the schools and colleges are reopening. Further, this prototype was submitted to the patent office under the name “A Wearable Face Shield” (Application no:202241000990) and the patent was published on January 21, 2022.

Their accomplishment bears testimony to the fact that unflinching determination towards your goals and consistent efforts to make them come true will always pay off. Designing a wearable face shield is a well-timed innovation as the pandemic shows no sign of retreat and face shield has become one of the daily necessities of all mankind.

About the Prototype

The wearable face shield is a medical protective device, and it comprises a frame for securing the shield to the head of a wearer, a transparent sheet extending from the frame, a detection circuit that is mounted on the frame, a switch, and a battery module. The detection circuit comprises of a control unit that processes the sensed data received from proximity and temperature sensors to generate output signals and an alerting unit that comprises LEDs, buzzer and it provides an indication of– (i) the presence of a detected external object within a pre-determined distance of the wearer (ii) the sensed body temperature of the wearer. The alerting unit is placed strategically to alert people via visual and audio signals respectively.

Such precautionary detection and proximity alert prototype can prove instrumental in early diagnosis and isolation aiding in crowd management and free movement in places of social gathering. Hence, a wearable face shield ensures adequate separation between persons and facilitates temperature monitoring and early detection of disease.

They are currently working on a project called “Human Monitoring System” (HUM). It is an all-pervasive system designed to measure and keep track of the heartbeat, blood pleasure, temperature, location, Spo2 level etc of the user. In the event of an emergency or critical drop in any of the vitals, the system can automatically alert the local hospital, ambulance service and relatives.

- Published in ECE NEWS, Faculty Achievements, News, Research News, Students Achievements

Dr Sujith Kalluri is honoured with “ICTSGS Service Award for Sustainable Development Goals (SDGs)”

Dr Sujith Kalluri from the Department of Electronics and Communication Engineering was honoured with the “ICTSGS Service Award for Sustainable Development Goals (SDGs)” in the recently held First International Conference on Technologies for Smart Green Connected Society 2021. The conference was jointly organised by the Electrochemical Society, USA, Yamagata University, Japan, and United Nations FAO, Italy. The award was presented for Dr Kalluri’s contributions in organising the international conference with the relevant audience. Dr Kalluri would further take up the role of Guest Editor in some of the prestigious peer-reviewed international journals.

The honour presented to Dr Kalluri further leads to research and professional collaboration with SPAST Foundation, Yamagata University Japan, and The Electrochemical Society USA.

- Published in ECE NEWS, Faculty Achievements, News

Guest Associate Editor in ‘Frontier in Control Engineering’ journal

The Department of Electrical and Electronics Engineering is Proud to inform you that Dr Tousif Khan N, Assistant Professor, and Faculty Coordinator, has been appointed as a Guest Associate Editor in Frontiers in Control Engineering, a peer-reviewed journal for the special issue on “Recent Advancements in Performance and Safety-Driven Robust Adaptive Control.”

The Department of Electrical and Electronics Engineering is Proud to inform you that Dr Tousif Khan N, Assistant Professor, and Faculty Coordinator, has been appointed as a Guest Associate Editor in Frontiers in Control Engineering, a peer-reviewed journal for the special issue on “Recent Advancements in Performance and Safety-Driven Robust Adaptive Control.”

This Research Topic is intended to give an insight into the latest development regarding the control design and analysis for the nonlinear systems under multiple uncertainties, matched and unmatched disturbances, measurement noises, actuator/sensor faults, and non-smooth nonlinearities. To render a promising control performance under resource-constrained communication networks, state constraints, control constraints, and other related issues are additional design objectives and the focus of this Research Topic.

In conclusion, developing an effective onboard implementable control approach for dynamical systems where safety, performance, uncertainty, and optimality are dealt with concurrently is the main objective of this special issue of the research journal Frontiers in Control Engineering.

- Published in Departmental News, EEE NEWS, Faculty Achievements, News, Research News