Research Paper on Computing In-memory Reconfigurable Adder Design

Prof. Siva Sankar Yelampalli and Dr Ramesh Vaddi, Associate Professor, from the Department of Electronics and Communication Engineering, along with research scholars Mr Birudu Venu, Mr Tirumala Rao Kadiyam, and Mr Koteswara Rao Penumalli, have jointly published a paper titled “Computing in-memory reconfigurable (accurate/approximate) adder design with negative capacitance FET 6T-SRAM for energy efficient AI edge devices” The paper introduces Computing in-memory (CiM) as a promising alternative to traditional von-Neumann architectures, focusing on its potential for energy-efficient AI edge computing with CMOS scaling. Additionally, they have explored the advancements in approximate computing in-memory (ACiM) techniques, aiming to further enhance the energy efficiency of these innovative architectures.

Abstract:

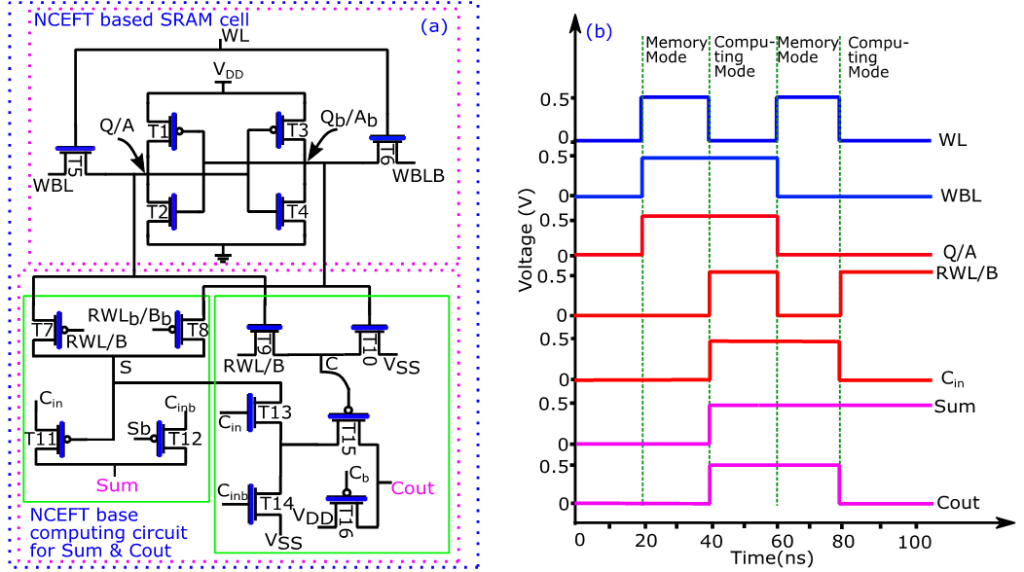

Computing in-memory (CiM) is an alternative to von Neumann architectures for energy-efficient AI edge computing architectures with CMOS scaling. Approximate computing in-memory (ACiM) techniques have also been recently proposed to further increase the energy efficiency of such architectures. In the first part of the work, a negative capacitance FET (NCFET) based 6T-SRAM CiM accurate full adder has been proposed, designed and performance benchmarked with equivalent baseline 40 nm CMOS design. Due to the steep slope characteristics of NCFET, at an increased ferroelectric layer thickness, Tfe of 3 nm, the energy consumption of the proposed accurate NCFET-based CiM design is ∼82.48% lower in comparison to the conventional/Non CiM full adder design and ∼85.27% lower energy consumption in comparison to the equivalent baseline CMOS CiM accurate full adder design at VDD = 0.5 V. This work further proposes a reconfigurable computing in-memory NCFET 6T-SRAM full adder design (the design which can operate both in accurate and approximate modes of operation). NCFET 6T-SRAM reconfigurable full adder design in accurate mode has ∼4.19x lower energy consumption and ∼4.47x lower energy consumption in approximation mode when compared to the baseline 40 nm CMOS design at VDD = 0.5 V, making NCFET-based approximate CiM adder designs preferable for energy efficient AI edge CiM based computing architectures for DNN processing.

Future research plans: Implementing reconfigurable computing in-memory (CiM) MAC for energy-efficient AI edge devices.

- Published in Departmental News, News, Research News

Examining the Impact of Bifurcation on Agricultural Development in Jharkhand: A Comprehensive Study

The Department of Economics is thrilled to announce the publication of Assistant Professor Dr Ghanshyam Kumar Pandey’s research paper titled, “Bifurcation and Agricultural Development in Jharkhand,” in Economic and Political Weekly. The paper delves into the developmental trajectory of Jharkhand following its bifurcation from Bihar in 2000 and examines the intricacies of agricultural development and the key determinants that have shaped its evolution post-separation.

Abstract:

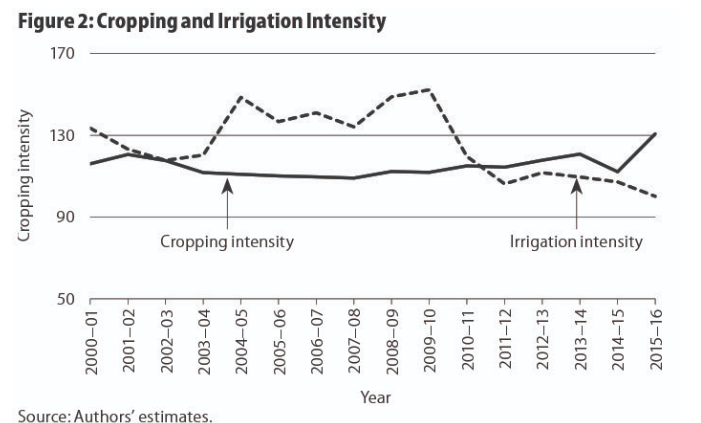

The cropping pattern in Jharkhand has significantly changed from 2000 to 2016, with shifts from the cultivation of cereals to non-cereals. An increase in the crop area and diversification towards high-value crops have accelerated overall agricultural growth. Capital formation and better infrastructure facilities, along with improved fertiliser consumption and irrigation, will foster agricultural development in Jharkhand

Practical implementation:

This study shows the development path of Jharkhand after bifurcation from Bihar in 2000. The study deals with the process of agricultural development and determinants of agricultural development after its bifurcation.

- Published in Departmental News, Economics Current Happenings, Economics News, News, Research News

Revolutionising Cooling Technology: Patent Granted for Innovative Fabric Design

The Department of Physics is thrilled to announce a remarkable milestone in sustainable technology. Dr Sabyasachi Mukhopadhyay, Associate Professor and Ms Sreelekha Bhuvaneswari, BSc student has been officially granted a patent for their groundbreaking invention: “A fibre material with moisture retention capacity with thermal tolerance and a method for manufacture of the same.”

The Department of Physics is thrilled to announce a remarkable milestone in sustainable technology. Dr Sabyasachi Mukhopadhyay, Associate Professor and Ms Sreelekha Bhuvaneswari, BSc student has been officially granted a patent for their groundbreaking invention: “A fibre material with moisture retention capacity with thermal tolerance and a method for manufacture of the same.”

This pioneering material, distinguished by its Application Number 202141023375, stands at the forefront of cooling technology. It promises to enhance thermal regulation while prioritising environmental sustainability.

Dr Mukhopadhyay’s invention is poised to make significant contributions to the field of material science, offering a versatile solution that holds potential applications across various industries. The department extends its heartfelt congratulations to the duo on this significant achievement and looks forward to the positive impact his work will continue to have on our community and beyond.

Abstract:

The project, with the patent application number 202141023375, develops a methodology to design a fabric cloth that would replace the use of air conditioners. This cloth design is inspired by Saharan silver ants which regulate their body temperatures in the scorching desert heat and also from the cooling properties of clay. This research would significantly scale down the usage of AC and other cooling devices in warm places, thus reducing the use of electricity and emission of greenhouse gases to the environment. As this cloth would be environment friendly with long durability and cost-efficiency, Sreelekha hopes that this research would bridge the socioeconomic divide of haves and have-nots between communities.

Explanation of the Research in Layperson’s Terms :

Using room conditioning AC during these times, especially with lower temperatures is very risky. Virus spread with closed circulated air or prolonged cold temperatures while breathing, so thus using air conditioning is bad. With this in mind, we need an efficient way of cooling in the snoring temperatures. We propose developing a fabric that integrates clay (Its primary mineral is kaolinite; clay may be generally described as 40% aluminium oxide, 46% silicon oxide, and 14% water.) in its synthesis; clay is known for its cooling properties given enough water to retail and proper reflection techniques for heat throughout the fabric inspired from uniquely shaped hairs with triangular cross-sections as in arrangement employed by the Saharan silver ants. This model not only conserves energy compared to room cooling but also is very practical, wherein we can dampen the fabric with the least water and retain its cooling for long hours. This Fabric could be employed in a variety of settings, for example, in making carpets and curtains in a house to keep the room temperature regulated.

Practical Implementation and Social Implications:

The research would significantly scale down the usage of AC and other cooling devices in warm places, thus reducing the use of electricity and emission of greenhouse gases to the environment. As this cloth would be environment friendly with long durability and cost-efficiency, Sreelekha hopes that this research would bridge the socioeconomic divide of haves and have-nots between communities.

The Title of Patent in the Citation Format

“A fibre material with moisture retention capacity with thermal tolerance and a method for manufacture of the same” with Application Number: 202141023375

Collaborations:

Prof. Seeram Ramakrishna, Professor of Materials, National University of Singapore

Future Research Plans:

The forthcoming endeavour encompasses the commercialisation of this pioneering concept to render it widely accessible and applicable on a larger scale.

- Published in Departmental News, News, Physics News, Research News

1st Research Scholar’s Summit: A Symposium of Ideas and Innovation

“The very idea of a platform such as this is to promote multidisciplinary collaborative research,” emphasised Prof. K Hemachandra Reddy, Chairman, Andhra Pradesh State Council of Higher Education (APSCHE), encapsulating the spirit of the 1st Research Scholar’s Summit hosted at SRM University-AP in partnership with the Government of Andhra Pradesh. The event was staged to reinforce research within academic circles and herald a new phase of learning. The summit was attended by esteemed dignitaries like Prof. Korukonda Babji, Vice Chancellor Dr Y S R University of Health Sciences; Prof. Ramesh Srikonda, Director-School of Planning and Architecture; Dr M Balakrishnan, IIT, Delhi, along with Vice Chancellor, Prof. Manoj K Arora; Registrar, Dr R Premkumar, Deans, Faculty, and Students.

In his keynote address, Vice Chancellor Prof. Arora emphasised the pivotal role of such summits in fostering a conducive environment. He stated, “We live in a world of collaborations, and a summit like this gives an opportunity to interact, establish partnerships and forge scholarly excellence”. He highlighted the varsity’s research acumen in the form of patents, technology transfers, research publications, start-ups, and incubations. He also declared that the varsity would be open to sharing its state-of-the-art research infrastructure among the broader demography in order to foster a research mindset among all.

Prof. Ranjit Thapa, Dean-Research at the university, highlighted the participation of 150 PhD scholars from diverse institutions. His speech reflected the tireless commitment to building the university’s scientific fortitude. Prof. Srikonda underscored the significance of technological advancement and innovation. He praised the summit for being a stage that will offer pragmatic solutions to societal challenges and commended its tagline – “Inspire, Ignite, Innovate,” for aligning with its core objectives.

Prof. Korukonda Babji and Prof. M Balakrishnan, pivotal figures in academia, articulated the transformative role of cutting-edge research in elevating society. They emphasised the potential of such forums in catalysing groundbreaking changes in research.

The summit showcased presentations from doctoral scholars, encompassing 60 poster presentations and 90 oral presentations, organised across 8 thematic areas. The summit concluded with a valedictory function, and tokens of appreciation were presented to the dignitaries by the Vice Chancellor, Registrar, Deans, and convenors, Dr Ramanjaneya Reddy and Dr Sabyasachi Chakrabortty, and members of the organising committee.

- Published in News, Research Conferences, Research News