Wire Arc Additive Manufacturing (WAAM) is revolutionizing how we make metal components, especially when it comes to materials like 304L austenitic stainless steel—a popular choice in industries such as aerospace, automotive, and healthcare due to its durability and corrosion resistance. The research paper titled “Microstructural Characteristics and Properties of Wire Arc Additive Manufactured 304L Austenitic Stainless Steel Cylindrical Components by Different Arc Welding Processes” published by Dr Maheswar Dwivedy, Associate Professor, Department of Mechanical Engineering and his post-doctoral scholar Dr B Prasanna Nagasai explores this innovative manufacturing method in detail, focusing on how different welding techniques affect the end product.

Overall, this research indicates that WAAM, with its different welding techniques, can produce 304L stainless steel cylinders that potentially outperform those made by conventional forging, both in terms of material efficiency and mechanical properties. Such findings are significant as they point towards more sustainable and cost-effective manufacturing methods that do not sacrifice quality.

Abstract

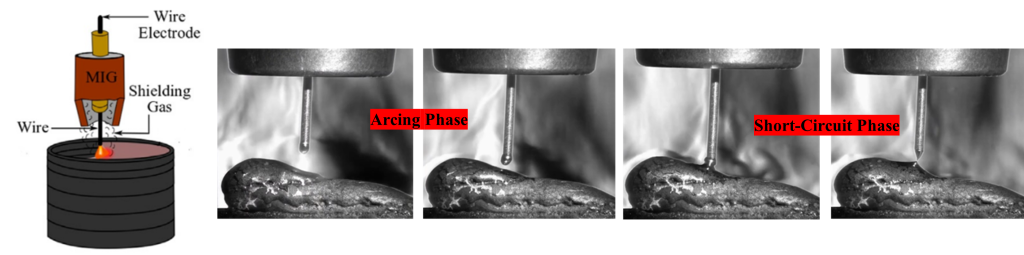

Wire arc additive manufacturing (WAAM) is an advanced additive manufacturing (AM) technology that offers low cost and high deposition rates, making it suitable for building large metal parts for structural engineering applications. However, various welding procedures result in differing heat inputs and repetitive heating treatments throughout the deposition process, which can affect the microstructural and mechanical characteristics of the parts. In the current study, cylindrical parts made of 304L austenitic stainless steel (ASS) were manufactured using the WAAM technique, employing both gas metal arc welding (GMAW) and cold metal transfer (CMT) processes. This study explores the correlation between WAAM techniques and their effects on the bead geometry, microstructure and mechanical properties. The paper presents detailed analyses of the microstructure using techniques such as optical microscopy, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD). The research findings suggest that the choice of arc welding process significantly affects the grain size, phase distribution, and defect formation within the 304L stainless steel, thereby influencing the mechanical properties and overall performance of the manufactured components. The WAAM-processed 304L ASS cylinders showed better performance compared to those manufactured using traditional industrial forging standards, indicating that WAAM-processed 304L ASS cylinders are suitable for industrial applications. This comprehensive evaluation provides insights into optimising welding processes for enhanced quality and performance of stainless steel cylindrical parts.

Highlights of the research

- Controlling heterogeneous microstructures in WAAM-processed 304L stainless steel is challenging.

- GMAW vs. CMT impacts on 304L ASS microstructure analysed.

- The upward growth of coarse austenite/ferrite morphologies is controlled by the wire retraction mechanism.

- CMT produced finer dendrites and more ferrite morphologies.

- WAAM 304L ASS components outperformed the wrought 304L ASS and forged 304L ASS.

Practical implementation/Social implications of the research

The practical implementation of Wire Arc Additive Manufacturing (WAAM) for 304L austenitic stainless steel could revolutionise multiple industries, including aerospace, automotive, medical devices, maritime, and energy, by allowing the production of complex, custom, and durable components with greater efficiency and reduced material waste. This shift not only promises economic benefits like cost reduction and job creation in advanced manufacturing sectors but also carries significant environmental advantages by minimising waste and the carbon footprint associated with traditional manufacturing processes. Furthermore, the technology enhances supply chain resilience by enabling local, on-demand production, which could be crucial during global disruptions. Socially, WAAM could increase access to customised medical aids in low-income regions, fostering greater equality. The adoption of WAAM thus holds the potential to impact manufacturing practices profoundly, driving innovation, sustainability, and inclusivity across various sectors.

Collaborations

Dr V Balasubramanian, Professor & Director, Centre for Materials Joining & Research (CEMAJOR), Annamalai University, Tamilnadu.

In the future, the research team plan to focus on developing Functionally Graded Materials (FGMs) of nickel and stainless steel using Wire Arc Additive Manufacturing (WAAM). This research will aim to leverage the unique properties of each metal to create components with tailored functional performance for demanding applications. Key challenges will include optimising material interfaces, controlling deposition processes, and ensuring structural integrity.