Bird strikes are a crucial phenomenon that should be taken into consideration while designing aircraft. Bird strikes have been reported since the early days of flight causing fatal disasters. It is estimated that around 300 people were killed, and several aircraft were destroyed because of bird strikes. A great deal of research has been conducted to tweak the design of aircraft to bring down the impact of bird strikes. Prof Prakash Jadhav and his PhD scholar Gruhalakshmi Yella from the Department of Mechanical Engineering have published a paper offering an appropriate solution in this regard.

Bird strikes are a crucial phenomenon that should be taken into consideration while designing aircraft. Bird strikes have been reported since the early days of flight causing fatal disasters. It is estimated that around 300 people were killed, and several aircraft were destroyed because of bird strikes. A great deal of research has been conducted to tweak the design of aircraft to bring down the impact of bird strikes. Prof Prakash Jadhav and his PhD scholar Gruhalakshmi Yella from the Department of Mechanical Engineering have published a paper offering an appropriate solution in this regard.

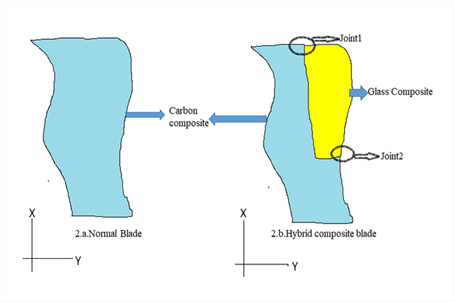

Their paper titled “Hybrid joint interface in composite fan blade subjected to bird strike loading” has been published in the international journal, ‘Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science’ having an impact factor of 1.76. The research puts forward an ideal solution to alter the design of the aircraft fan blades which are frequently being subjected to such collisions. The duo proposes a hybrid joint interface using two fibres instead of a single fibre.

Some delamination failures observed in the trailing edge of the blades could probably increase the effect of such bird strikes. For rectifying the delamination problem, the proposed solution is to use a material with higher strain capability such as glass fibres in the areas on the fan blade which are prone to delamination, while maintaining carbon material on the remaining blade. The concept is proved by first performing a static analysis on 3D FEA coupons with an in-built hybrid interface joint and next by performing a dynamic bird strike analysis on 3D FEA coupons and sub-element models with an in-built hybrid interface.

Abstract of the Research

Fan blades are one of the most important components of an aircraft engine. Bird strikes on fan blades have always been a cause of worry and it can cause slices of birds to hit other parts of the engine which may lead to greater damage. Bird strikes cannot be completely avoided. Although current composite blades can withstand the bird strike impact, some delamination failures are still observed on the trailing edge side of the blade, possibly due to vibration bending modes. This paper talks about using two fibres in a composite blade instead of the current single fibre one. For this to be feasible, two fibre joints at various locations on the blade must be properly designed. The design criteria used here is the lowest inter-laminar shear strain level at critical joint locations.