Chemical Engineering Journal publishes paper of Dr. Lakhveer Singh with Impact Factor 8.34

Dr. Lakhveer Singh, Assistant Professor, Department of Environmental Science, SRM University AP, Andhra Pradesh published a paper in the Chemical Engineering Journal with an Impact Factor of 8.34. His paper titled, Breaking the Loop: Tackling Homoacetogenesis by Chloroform to Halt Hydrogen Production-Consumption Loop in Single Chamber Microbial Electrolysis Cells is published in collaboration with Oregon State University.

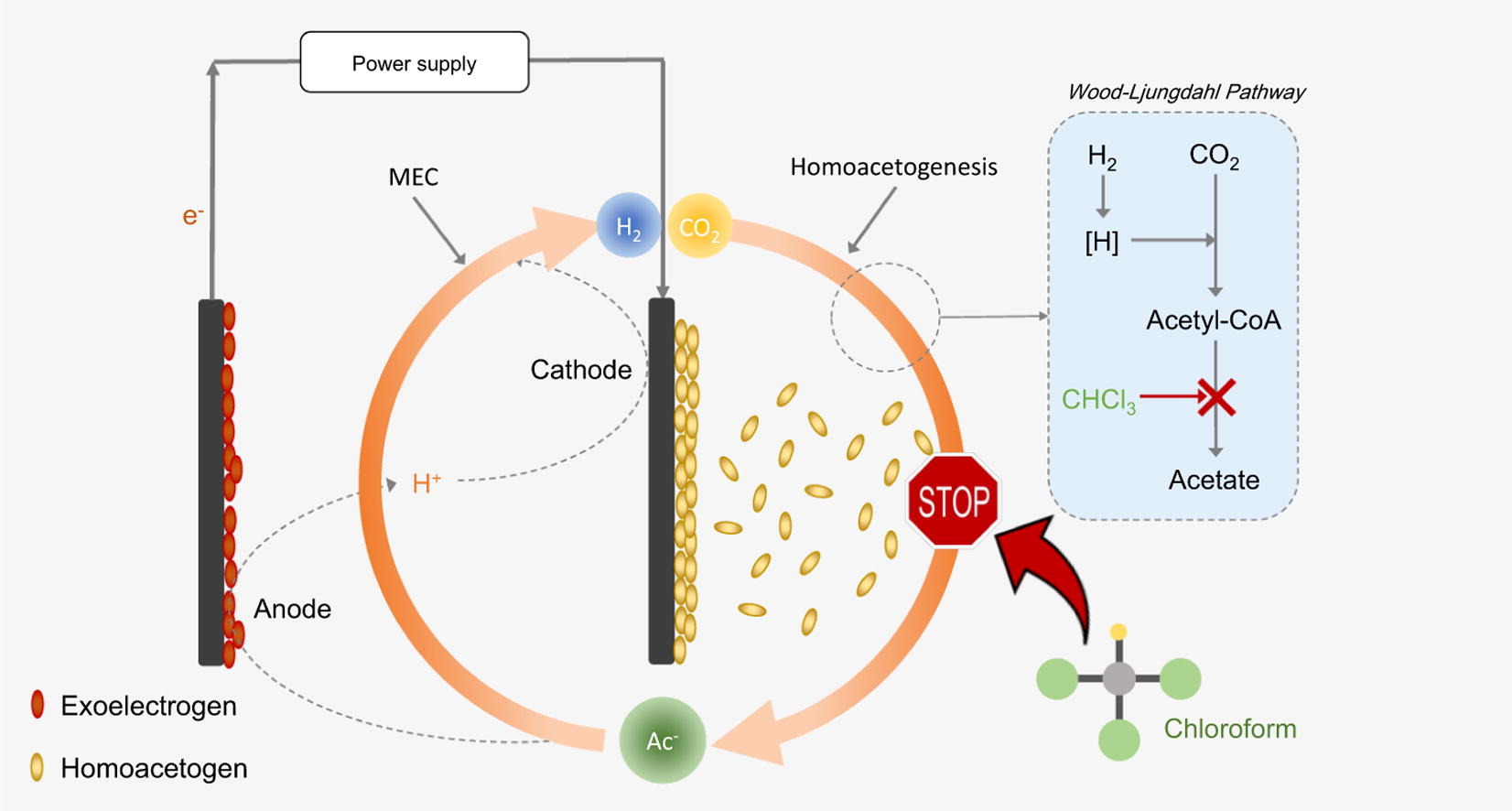

Single Chamber Microbial Electrochemical Cells reactor is used to produce hydrogen. Since wastewater is used in the process, hydrogen consumers are present inside the reactors. The presence of homo acetogenesis and hydrogen production-consumption loop significantly hinders the efficient hydrogen recovery from this reactor. Removal of homo acetogenins remained a challenge that is mitigated by the research work conducted in this paper. Dr. Lakhveer informs, “Prof. Hong Liu is the mother of the bioelectrochemical system. I used to work with her for 1.5 years during my Post Doctorate. We developed the method to inhibit homo acetogenins in bioelectrochemical fuel cells for the first time to exhibit homo acetogenins which enhance the hydrogen production in scaled-up microbial electrochemical (MEC).”

Method to inhibit homo acetogenins in bioelectrochemical fuel cells

Method to inhibit homo acetogenins in bioelectrochemical fuel cells

A small concentration of chloroform is used in the process, which after the experiment leaves traces of merely 0.001% which is negligible. Furthermore, 0.02 ml chloroform is used in ten litres of reactors, negating the chance of causing damage to the environment. “Microbial community analysis revealed that the amount ofhomoacetogenic Acetobacterium spp. was eliminated in the cathodic biofilms and planktonic cells by chloroform.”, enlightens Dr. Lakhveer. This method can also be applied in large scale reactors to enhance hydrogen production by inhibiting homo acetogenins. The hydrogen production rate is nearly 20 litres per hour from the reactor. The application of this reactor is the production of energy which can be used as an alternative to conventional fuel.

Advancing the work, Dr. Lakhveer aspires to improve this method in the future, through reducing the residual chloroform concentration and developing more environment-friendly inhibitor using similar mechanisms, that may lead to the practical application in MECs.