The Department of Mechanical Engineering is thrilled to announce a significant breakthrough in materials science has been achieved through the diligent research efforts of Prof. G S Vinod Kumar, Professor and Head of the Department and his Ph.D. scholar, Mr Dipak Bhosale in their latest paper, “Production, stability and properties of ultrafine MgAl2O4 (Spinel) particles stabilized Mg-3Ca alloy foams”. The study focuses on the development and detailed analysis of Mg–3Ca alloy foams, uniquely enhanced by ultrafine MgAl2O4 (spinel) particles. This innovative research outlines a novel methodology for improving the mechanical properties of magnesium foams, providing unparalleled advantages for a multitude of industrial applications.

Abstract

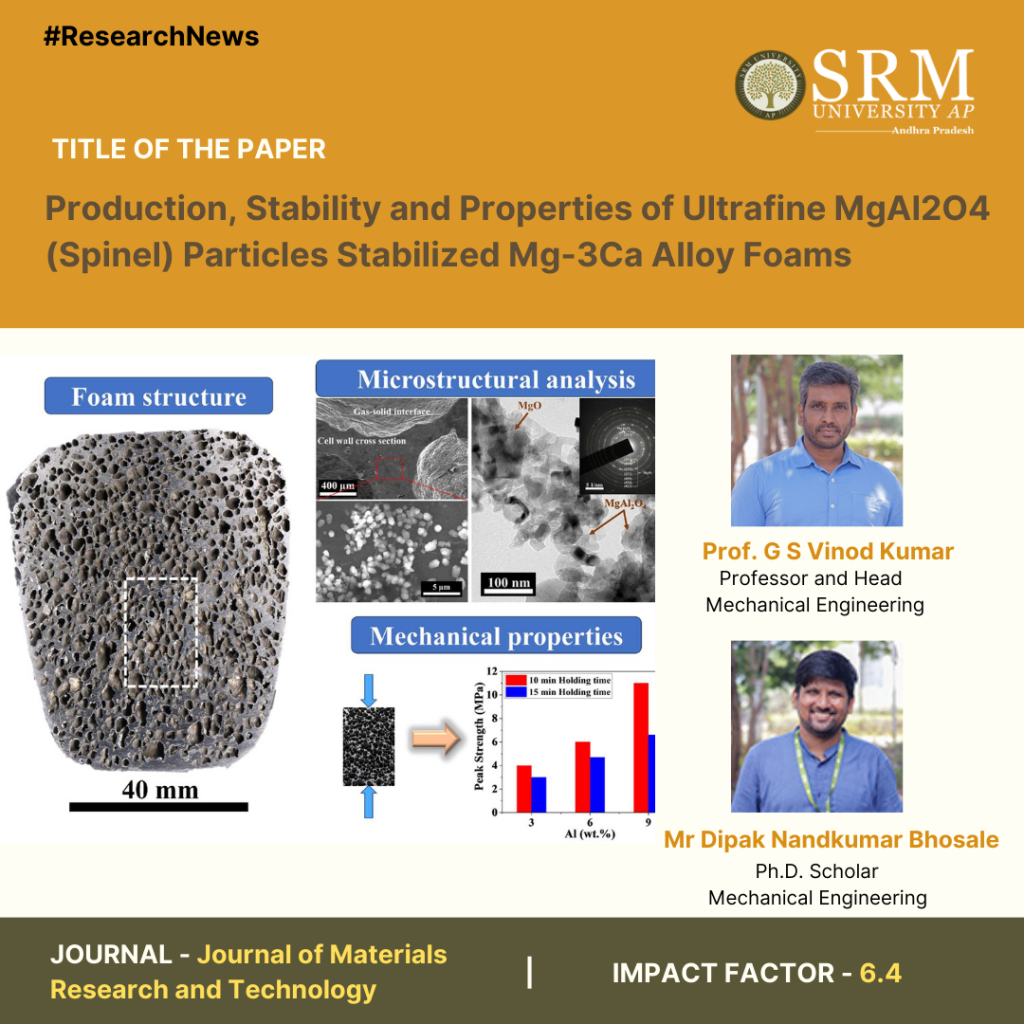

The present work reports the synthesis and mechanical behaviour studies of Mg–3Ca alloy foams stabilized by ultrafine MgAl 2 O 4 (spinel) particles. The MgAl 2 O 4 particles were created in-situ in the Mg–3Ca alloy melt through the reaction of Mg, Al and O. Foaming was done by adding dolomite (CaMg(CO 3 ) 2 ) as a blowing agent in the melt. The foaming behaviour was studied for different MgAl 2 O 4 content in Mg–3Ca and holding times (10 and 15 min). The study reveals that the presence of MgAl 2 O 4 significantly influences the foaming behaviour of Mg–3Ca alloy resulting in equiaxed cell structure, uniform cell size distribution, and higher expansion in comparison to the Mg–3Ca alloy foam, which contains only MgO and CaO. An in-depth phase and microstructural analysis were performed to investigate the particles present in the gas-solid interface of the foam that contribute to foam stabilization. The quasi-static compression studies of foams exhibited better compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3) in comparison to the Mg foams reported in the literature. The ductility of the Mg foams was also measured and compared with that of existing aluminium foams.

Research Highlights:-

- Innovative Synthesis: The MgAl2O4 particles are synthesized in situ within the Mg–3Ca alloy melt via a controlled reaction involving Mg, Al, and O. This process ensures the uniform dispersion of spinel particles, which is critical for the foam’s structural integrity and performance.

- Foaming Process: By employing dolomite (CaMg(CO3)2) as a blowing agent, the research team meticulously explored the foaming behaviour under various MgAl2O4 contents and holding times (10 and 15 min). The findings highlight a marked improvement in foam expansion and stability.

- Structural and Mechanical Analysis: Through comprehensive phase and microstructural analyses, the pivotal role of MgAl2O4 particles at the gas-solid interface in stabilizing the foam structure was uncovered. Quasi-static compression tests revealed outstanding compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3), surpassing existing benchmarks for magnesium foams.

Key Properties and Applications:-

- Low Density & High Strength-to-Weight Ratio: The Mg–3Ca alloy foams showcase an optimal balance of low density and high mechanical strength, rendering them ideal for lightweight structural applications.

- Enhanced Energy Absorption: Their unique cellular structure provides superior energy absorption capabilities, suitable for impact and crash-resistant applications.

- Biocompatibility: Owing to magnesium’s biocompatibility, these foams are highly promising for biomedical applications, including bone implants and scaffolds for tissue engineering.

- Thermal Conductivity & Corrosion Resistance: Additionally, these foams exhibit advantageous thermal and corrosion-resistant properties, broadening their applicability across various environmental conditions.

Transformative Impact Across Industries:-

- Aerospace and Automotive: The significant weight reduction capabilities, coupled with uncompromised strength, position the Mg–3Ca alloy foams as revolutionary materials for component design in the aerospace and automotive sectors.

- Biomedical: Their biocompatible nature and structural characteristics make these foams an excellent option for medical implants and scaffolds, poised to improve patient outcomes in orthopaedics and tissue engineering significantly.

- Energy and Beyond: From thermal management solutions in renewable energy systems to applications in sports equipment, the potential uses for these magnesium foams are extensive and diverse, heralding a new chapter in material science.

This groundbreaking research not only advances the field of magnesium foam technology but also paves the way for new possibilities in lightweight, high-performance materials across various industries. The team is dedicated to further exploring the capabilities of these innovative materials and eagerly anticipates partnering with industry stakeholders to transition these advancements from the laboratory to commercial applications.