Interdisciplinary Research on Groundwater Fluoride Contamination

Assistant Professors – Dr Kousik Das, Dr Harish Puppala, Associate Professor- Dr Pankaj Pathak, Uttiya Dey, along with Research Scholars – Mr Mijanur Mondal, Ms Sudeshna Chell, Ms Sumana Dutta, and Ms Pankaj Kumar come up with an interdisciplinary research breakthrough in their paper, “Community-Level Vulnerability of Groundwater Fluoride Contamination and Exposure by the Application of Multi-Criteria Model.” The authors examine fluoride exposure in villages like Chintal Cheruvu, Rompicherla, Shantamangalur, Thimmapur, and Nadendla.

Assistant Professors – Dr Kousik Das, Dr Harish Puppala, Associate Professor- Dr Pankaj Pathak, Uttiya Dey, along with Research Scholars – Mr Mijanur Mondal, Ms Sudeshna Chell, Ms Sumana Dutta, and Ms Pankaj Kumar come up with an interdisciplinary research breakthrough in their paper, “Community-Level Vulnerability of Groundwater Fluoride Contamination and Exposure by the Application of Multi-Criteria Model.” The authors examine fluoride exposure in villages like Chintal Cheruvu, Rompicherla, Shantamangalur, Thimmapur, and Nadendla.

Abstract

Elevated fluoride (F⁻) levels in groundwater, primarily due to geogenic processes, pose significant health risks, including dental and skeletal fluorosis and neurological disorders. This study aimed to quantify source-dependent F⁻ exposure at the community level in selected tropical dry regions of Andhra Pradesh, India. These locations include Chintal Cheruvu, Rompicharala, Shantamangalur, Thimmapur, and Nadendla. Community surveys and drinking water sample analyses were conducted in these regions. Dental Fluorosis Index (DFI) used to estimate exposure levels across age and sex groups. Findings of surveys indicate that groundwater consumption with high F⁻ (4.3 mg/L) results in the highest exposure dose (0.62 mg/kg/day), with Chintal Cheruvu identified as the most affected. A strong positive correlation was observed between exposure dose, water F⁻ content, and the Community Fluorosis Index (CFI). Dental fluorosis prevalence exceeded 80% across all age groups, and household surveys revealed 100% unawareness of F⁻ exposure risks. The magnitude of FII for Chintal Cheruvu is 0.563 which is highest among the considered regions indicating that it is most impacted region that needs remedial measures first in the hierarchy. Rompicharala with FII as 0.252, Nadendla (0.223), Shantamangalur (0.214), and Thimmapur (0.188) follows the hierarchy.

Explanation in layperson’s terms.

The outcome of the study concludes that regionally most of the places of Andhra Pradesh is affected the by the groundwater fluoride contamination. People are getting affected by the consumption of high fluoridated water which is visible from the dental fluorosis. The area is having high groundwater fluoride is having highest severe dental fluorosis cases. Among the villages, Chintal Cheruvu had the highest fluoride level while Thimmapur had the lowest. Signs of dental fluorosis were most noticeable among younger individuals who are still developing. The exposure dose varied across villages, with Chintal Cheruvu having the highest exposure dose followed by Rompicharala. Other symptoms of fluorosis, such as skin allergies and body pain are also predominant. Most villages had alternative sources of drinking water, except for Chintal Cheruvu, where residents continued to use contaminated water due to a lack of alternatives. There is a clear link between lack of awareness about fluoride toxicity and higher exposure levels as apparent from the questionnaire survey.

Practical /Social Implications

The immediate action is necessary to reduce fluoride exposure, provide safe drinking water, and raise awareness about fluoride toxicity to meet sustainable development goals by 2030. The findings highlight the need for integrated approaches combining mitigation, education, and sustainable practices to tackle fluoride contamination and improve the overall well-being of affected communities.

- Published in CIVIL NEWS, Departmental News, ENVS News, News, Research News

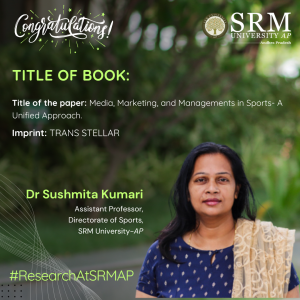

Dr Sushmita on Media, Marketing, and Management in Sports

Dr Sushmita Kumari, Assistant Director of Sports, has authored a book titled “Media, Marketing, and Management in Sports: A Unified Approach.” Her publication presents a thorough examination of the pivotal roles that media relations, marketing strategies, and public relations play within the sports industry. Aimed at both students and professionals, the book delivers valuable perspectives on fan engagement, sponsorship dynamics, and effective crisis management. Through the use of real-world examples, Dr Sushmita highlights the transformative influence of digital media and the necessity for global adaptability in sports communication, making it an indispensable resource for anyone aspiring to succeed in the field of Sports.

Dr Sushmita Kumari, Assistant Director of Sports, has authored a book titled “Media, Marketing, and Management in Sports: A Unified Approach.” Her publication presents a thorough examination of the pivotal roles that media relations, marketing strategies, and public relations play within the sports industry. Aimed at both students and professionals, the book delivers valuable perspectives on fan engagement, sponsorship dynamics, and effective crisis management. Through the use of real-world examples, Dr Sushmita highlights the transformative influence of digital media and the necessity for global adaptability in sports communication, making it an indispensable resource for anyone aspiring to succeed in the field of Sports.

Abstract:

The book, provides a comprehensive exploration of sports communication and management. It highlights the significance of media relations, marketing strategies, and public relations in shaping the success and image of sports entities. By integrating real-world examples, it delves into the interplay of traditional and digital platforms, showcasing their role in fan engagement, sponsorships, and crisis management. The content equips readers with the knowledge and skills necessary to navigate the evolving landscape of sports media and branding.

Target Audience:

The book is designed for students and professionals in sports management, communication, and media industries. It caters to academics, sports enthusiasts, PR practitioners, and industry leaders who seek to enhance their expertise in sports branding, marketing, and public relations.

Collaboration Details:

Acknowledgments highlight the contributions of mentors, colleagues, students, and industry experts, emphasizing the book’s foundation in academic and practical insights. It also includes case studies and experiences from media professionals, enhancing its relevance and applicability.

Social or Practical Implications:

- Digital Transformation: The book addresses the transformative power of social and digital media in fan interaction and brand promotion.

- Crisis Management: It provides strategies for managing crises in sports, ensuring sustained reputation and stakeholder trust.

- Global Engagement: It emphasizes the importance of adapting to globalization and cultural sensitivities in sports communication.

- Sponsorship Dynamics: Insights into sponsorship management underline its role in generating revenue and aligning brand values.

- Published in News, Research News, Sports News

Revolutionising Cardiac Health Monitoring with Cutting-edge Innovation

The research team consisting of Dr Manjula R, Assistant Professor from the Department of Computer Science and Engineering and her students, Mr Adi Vishnu Avula, Mr Abdul Jawad Khan, Mr Chiranjeevi Thota and Ms Kavyanjali Munipalle has published their patent titled “System For Determining And Predicting Scattering Coefficients Of Myocardium Tissue In Near-Infrared-Band For In-Vivo Communications” in the Indian Patent Office with the Application no: 202441090535.

Their research harnesses the power of machine learning and near-infrared (NIR) technology to analyse myocardium tissue with unmatched precision. By predicting scattering coefficients using advanced models like Gradient Boosting and Artificial Neural Networks (ANN), this breakthrough enables non-invasive diagnostics, early detection of heart conditions, and enhanced medical imaging. From 6G-enabled smart hospitals to regenerative medicine, this technology is set to transform healthcare.

With this groundbreaking invention, Dr Manjula and her research team pave the way for the future of connected, intelligent cardiac care!

- Published in CSE NEWS, Departmental News, News, Research News

A Critical Review in Understanding Equity and Social Justice in Mathematics Education

Dr Jayasree Subramanian, Associate Professor from the Department of Mathematics, has recently published a book chapter titled “Strengthening Equity and Social Justice Research in Mathematics Education Through Critical Interrogations of White Supremacy and Settler Colonialism” in the Fourth International Handbook of Mathematics Education by Springer Publications.

Abstract

In this chapter, we contextualise a suggested approach to strengthening equity and social justice research in mathematics education by inserting the mathematics education enterprise into two world events of 2020: the global COVID-19 pandemic and the global resurgence of the Black Lives Matter movement. Our intent in doing so is to underscore how white colonialism is forever present everywhere in structures and institutions around the globe, including those of the mathematics education enterprise. The logic of both white supremacy and settler colonialism are described next and then combined into a compounding scheme of colonising white supremacist logic. To illustrate that colonizing white supremacist logic is not a manifestation of only the West, a discussion of the conflicts and contradictions of white supremacy and Brahminical supremacy in the mathematics education enterprise of postcolonial India is offered. Brief summaries of the five chapters in the “Equity and Social Justice” section of this Handbook are then provided; we highlight how the chapter authors interrogated colonialising white supremacist logic within their respective chapters and point toward additional opportunities. In concluding the chapter, we feature recent USA-based mathematics education research to illustrate different possibilities when equity and social justice research is strengthened through critical interrogations of white supremacy and settler colonialism.

About the Book

The Fourth International Handbook discusses developments not recognised or dealt with entirely in the first three Springer Mathematics Education handbooks and tackles controversial issues in the field. After starting with a provocative introductory chapter which asks whether controversy is a healthy feature of international mathematics education, the four following sections cover: (a) mathematics education in Asia; (b) the roles of theory in research and practice; (c) equity and social justice; and (d) curriculum and change. These themes are taken up in 28 chapters by 60 authoritative authors from all continents. The four sections are structured based on past, present, and future aspects.

Like the first three mathematics education handbooks, this handbook provides a valuable resource for teachers, practitioners and researchers, education policymakers, mathematicians, and graduate and undergraduate students.

Co-authors of the Book Chapter

1. David W. Stinson, College of Education and Human Development, Georgia State University, Atlanta, GA, USA (Lead Coauthor)

2. Cathery Yeh, Center for Asian American Studies, University of Texas, Austin, TX, USA (Fellow coauthor)

- Published in Departmental News, Math News, News, Research News