Cost-effective shield against Coronavirus

Dr. Panchagunula Jayaprakash designs an improved alternative to regular masks

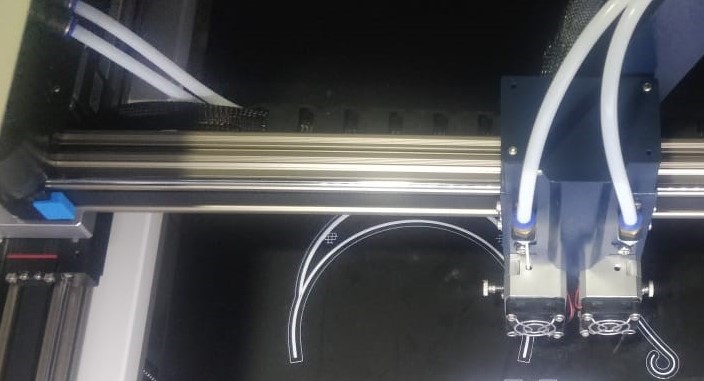

Dr. Panchagunula Jayaprakash, Assistant Professor, Department of Mechanical Engineering, has designed a FACE SHIELD embedded with 3D printing technology. During this pandemic that has led to an unprecedented global crisis, this face protection devised to protect users from the Novel Coronavirus, is made available at the minimum rate of Rs. 20 each. The major drawback of the commercially available Face Shields for engineering applications is its heavy weight which causes discomfort if worn for a longer period of time. This face mask that uses 3D printing technology alleviates the limitations of the regular masks currently used by doctors, policemen, and journalists.

Head mounted Face Sheild

Head mounted Face Sheild

“With the advent of Covid-19, and due to the shortage of personal protective equipment, the health workers such as Doctors, Sanitary staff and Police are also getting infected. As they are the backbone of the society, I thought of designing a light weight Face Shield using 3D Printing (3DP) or Additive Manufacturing technique. The rudimentary advantages of 3D printing technology is the design flexibility and less lead time to manufacturing. “, explains Dr. Jayaprakash.

Creation of CAD model

Creation of CAD model

3D Printing

3D Printing

The regular masks barely cover the nose and mouth, whereas the Face Shield will be able to protect the eyes, mouth, nose, and ears so that one cannot get infected by the virus. Some of the medical and police personnel who use the regular masks suffer from facial irritation, making the Face Shield a comfortable and more effective alternative for all government officials on Covid-19 duty.

Physical component

Physical component

Dr. Jayapraksh further says, “While manufacturing the Face Shield, 3D printing technology is used for designing a headband, upon which a 100 micron thick transparent plastic sheet is attached to ensure superior protection against the virus. It prevents air, dust, and liquids that are contaminated to come in contact with people. Also, there are no probable side effects on using the mask. If the government approves of its marketing, the face mask can be distributed among the public to prevent the widespread of Novel Coronavirus.”

OHP sheet assembly

OHP sheet assembly

The management of SRM AP, Andhra Pradesh applauds Dr. Jayaprakash on designing the mask after relentlessly working on it for several days. Prof. Narayana Rao, Pro Vice-Chancellor of the University, has written to Adimulapu Suresh, Minister of Education, Andhra Pradesh, and Alla Kalikrishna Srinivas, Deputy Chief Minister of Andhra Pradesh, Minister for Health, Family Welfare and Medical Education, Andhra Pradesh, highlighting the importance of the facial cover and the many ways it can be regarded as a boon to the society as a whole. He said that the Face Shield would be beneficial to millions of students who would be attending regular classes once the educational institutions reopen.

- Published in Mechanical Engineering NEWS, News, Research News

Undergraduate students design e-bike for sustainable environment

Advancing the celebration, Prof D Narayana Rao, Pro Vice-Chancellor, SRM AP took the virtual podium to comment “Science and Technology is the driving force for the economic development of India. We need to encourage young scholars by providing a vibrant and conducive research environment. Expanding the frontiers of knowledge by triggering interest among students must be the priority of the institutions. Also, focus should be on translational research with societal applications through collaborative research to make our nation a global leader.”

The team comprises of undergraduate students – Mr Raviteja Reddy, Mr A Chaitanya, Mr P M Aditya, Mr K Praveen, K Yeshashwini, A Sravya, K Vasu, and G Priyanka along with faculty members – Dr Venkata N Nori, Associate Professor, and Dr Panchagnula Jayaprakash Sharma, Assistant Professor, Department of Mechanical Engineering. Aditya reveals, “We endured several challenges in various aspects of retrofitting the conventional petrol motorcycle. Also, designing a portable battery system, enhancing the performance of the Hub motor, Chassis improvements, etc. enriched our understanding of electric vehicles and manufacturing techniques.”

Conversion of IC engine bike to an e-bike is considered to be a potential business venture by the team. Sharing their forthcoming plans, Aditya informs, “We are working on additional designs and ideas to incorporate the best possible features to make the e-bike more reliable. We heartily thank Prof D Narayana Rao, Pro Vice-Chancellor, for his continuous support. Also, Dr Venkata Nori and Dr Jayaprakash propelled us to create a steadfast model by relentlessly helping us in improving our design to make our model more cost-effective.”

- Published in Mechanical Engineering NEWS, News, Research News

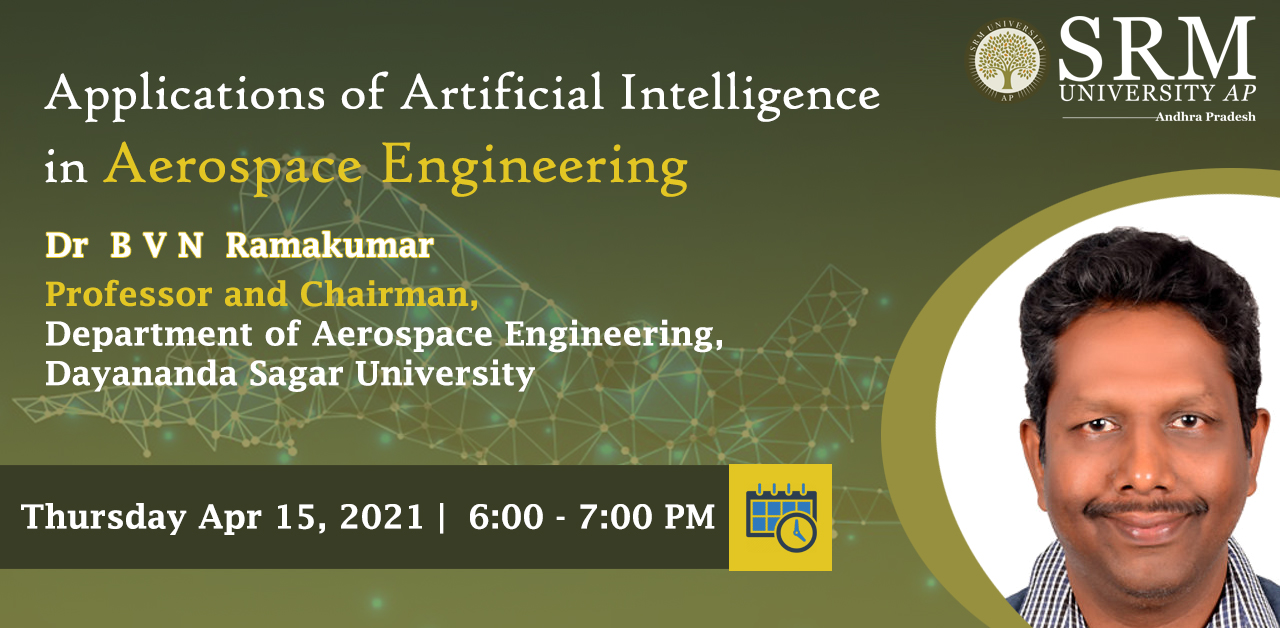

An Enthralling Webinar on “Applications of Artificial Intelligence in Aerospace Engineering”

On April 15, 2021, the Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, hosted a virtual lecture session with Dr B V N Ramakumar, Professor and HOD, Department of Aerospace Engineering, Dayananda Sagar University, Bangalore. Addressing the Webinar, Dr Lakshmi Sirisha Maganti and Dr Venkata Nori, Faculty, Department of Mechanical Engineering, handed over the podium to Dr Ramakumar. Initiating the discussion with a brief understanding of the background of Artificial Intelligence (AI), Dr Ramakumar described the AI Applications in Space, Civil and Defense industry. Apart from highlighting the overview and functionality of AI Applications in Aerospace Engineering, he outlined the challenges associated with it.

On April 15, 2021, the Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, hosted a virtual lecture session with Dr B V N Ramakumar, Professor and HOD, Department of Aerospace Engineering, Dayananda Sagar University, Bangalore. Addressing the Webinar, Dr Lakshmi Sirisha Maganti and Dr Venkata Nori, Faculty, Department of Mechanical Engineering, handed over the podium to Dr Ramakumar. Initiating the discussion with a brief understanding of the background of Artificial Intelligence (AI), Dr Ramakumar described the AI Applications in Space, Civil and Defense industry. Apart from highlighting the overview and functionality of AI Applications in Aerospace Engineering, he outlined the challenges associated with it.

Dr Ramakumar completed his bachelor’s from Ranchi University, and he pursued a master’s from Andhra University. Dr Ramakumar holds a Doctorate Degree from IIT Madras and has years of experience in research, academia and industry. Dr Ramakumar worked for Rolls Royce India Pvt Ltd and Honeywell Solutions Pvt Ltd. With contributions to the Auto Mechanics Industrial Sector, he also worked for the DMR Institute of Technology.

Dr Ramakumar was the visiting faculty at Manipal University. In terms of contribution to the field of engineering, he designed, developed, and analysed components for Boeing 777X, Airbus A350 and Honeywell HTF700 Engine Programme. Dr Ramakumar published papers in reputed National and International journals in addition to two patents to his credit.

Dr Ramakumar elucidated, “Artificial Intelligence is the broad sphere covering machine learning and deep learning as well. Moreover, a technique which mimics human behaviour”. Discussing the key players in the aviation industry, he explained the role of the mini-robots to capture the imagery clips of the inaccessible area in an aircraft. Implementation of the Artificial Reality techniques in the civil aviation industry is needed to reduce manual cost and time. AI applications manage the supply chain by gathering data as a part of the predictive measure. With the inclusion of automated tools, the civil aviation industry efficiently controls and optimises the security parameters.

During Dr Ramkumar’s proceeding, he added, “AI Application in aviation optimises the data related to flight scheduling, seat arrangement, cabin crew shift scheduling along with the management of the route mapping”. Starting from taking off to landing, AI Applications are being used widely in the aviation industry.

He further added that “Emerging as the dynamic technology, AI Applications marked their presence in the military intelligence too. Drones for military operations map the routes and record that in imagery forms to apprehend the nearby geographical location. The information stored in databases are sent and received without any manual meddling”.

Advancing to the next part of the discussion, Dr Ramakumar explained that “Speaking of the satellite link and communication, Robonauts are the new humanoid robots that would replicate the actual human beings by assisting in anything from gathering outer space information to exploring it”. Dr Ramakumar also propounds that “Productivity and Investment are few challenges amongst others that are common and would go hand in hand with the development of AI technology.” The discussion came to an end with an engaging Q&A session with the students followed by a Vote of Thanks by Dr Nori.

- Published in Departmental News, Mechanical Engineering NEWS, News, Webinars

SRM University-AP Student earns Erasmus Mundus Scholarship 2021

Since its inception, SRM University-AP, Andhra Pradesh, has retained its exalted heights of excellence and brilliance. Avid students over the years have brought laurels to the organisation with impressive research work, outstanding academic performance or Guinness World Record for spectacular artistry. Bismark Razak Haruna, a B. Tech Final Year Student at the Department of Mechanical Engineering, is deemed to be bestowed on the highly prestigious Erasmus Mundus scholarship. The globally acclaimed European Union-funded scholarship will help Bismark pursue the joint master’s degree programme in Decentralised Smart Energy Systems (DENSYS) in renowned universities of Europe.

Since its inception, SRM University-AP, Andhra Pradesh, has retained its exalted heights of excellence and brilliance. Avid students over the years have brought laurels to the organisation with impressive research work, outstanding academic performance or Guinness World Record for spectacular artistry. Bismark Razak Haruna, a B. Tech Final Year Student at the Department of Mechanical Engineering, is deemed to be bestowed on the highly prestigious Erasmus Mundus scholarship. The globally acclaimed European Union-funded scholarship will help Bismark pursue the joint master’s degree programme in Decentralised Smart Energy Systems (DENSYS) in renowned universities of Europe.

Bismark sets an example by being the first Ghanaian to get into the DENSYS program. He expressed that as part of the mobility scheme of the programme, he would pursue the first year at the University of Lorraine, Nancy, France, and continue the final year at the Polytechnic University of Catalonia, Barcelona, Spain. The Erasmus Mundus Scholarship help students enrol into the world’s best universities for masters and doctoral programmes with substantial benefits. Bismark shared his thoughts, “I welcome the opportunity to play an important role in increased electrification in Sub-Saharan Africa through the integration of renewable energy sources for a low carbon society”.

Approximately 392 aspirants applied for the DENSYS program globally, and out of 23 students from 17 countries, Bismark secured his place. Erasmus Mundus Scholarship Programme covers the expenditure involving the tuition fee, insurance, participation in activities such as the lab courses, excursion, research projects, financial support for housing, feeding, transportation and installation fee as well.

While speaking of his success, Bismark expressed his gratitude towards the SRM University-AP for consistently providing him with golden opportunities and resources. “From conceptualising undergraduate research project to studying abroad at UC Berkeley, the University has been a constant support. A special thanks to my motivators and mentors- Dr Prakash Jadav, Dr Satya Pramod Jammy, Dr Sarfaraz Hussain Halkarni, Dr Ram Kuresh Thakur, Dr Srabani Basu, Ms Revathi Balakrishnan for grooming and guiding me throughout the journey. I convey my sincere thanks to my buddies as well for helping me out with the scholarship application”, Bismark added while being ready for exploring the next chapter of his life in the European Union.

- Published in Departmental News, Mechanical Engineering NEWS, News, Students Achievements

SRM University-AP & Titan Company Ltd collaborate to engineer novel gold alloys for contemporary jewellery

SRM University-AP inked an MOU with Titan Company Ltd (TATA group,) Bangalore, for the project “Developing novel gold alloys for contemporary Jewellery application”. Titan has sanctioned Rs. 29.6 lakhs for the execution of the project to Dr G S Vinod Kumar, Associate Professor in the Department of Mechanical Engineering and Principal Investigator of the project. Dr Vinod is well known for his research in precious metals such as gold and silver for making lightweight and high strength alloys that can be used in jewellery making.

SRM University-AP inked an MOU with Titan Company Ltd (TATA group,) Bangalore, for the project “Developing novel gold alloys for contemporary Jewellery application”. Titan has sanctioned Rs. 29.6 lakhs for the execution of the project to Dr G S Vinod Kumar, Associate Professor in the Department of Mechanical Engineering and Principal Investigator of the project. Dr Vinod is well known for his research in precious metals such as gold and silver for making lightweight and high strength alloys that can be used in jewellery making.

The jewellery division of Titan Company Ltd (TANISHQ) will jointly work on this project by supplying Gold for lab-scale experiments. The Industrial scaling up trials of the technology will be carried out at Titan’s jewellery manufacturing plant at Hosur, Tamil Nadu.

This is the fourth project sanctioned by Titan Company Ltd to Dr G S Vinod Kumar and the second project in Gold. The first project “Hardening of 22Karat and 24Karat gold for lightweight and high strength jewellery application” was successfully completed in 2018 by Dr Vinod and his team. A joint patent between SRM and Titan Company Ltd has been filed and the jewellery produced from hard 22Karat gold is currently available in Titan showrooms under the brand-TANISHQ.

- Published in Mechanical Engineering NEWS, News, Research News

Dr Satya Pramod Jammy receives a grant to research missiles and space vehicles

Dr Satya Pramod Jammy, Associate Professor, Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, has received a total outlay of Rs. 38,61, 264/- from Department of Science and Technology (DST) Science and Engineering Research Board, Government of India, to work on the project titled “Wall effects in Shock wave boundary layer interactions”. Using the grant, state-of-the-art HPC computational facilities based on the exciting General Purpose Graphic Processing Units (GPGPU’s) will be set up to perform missiles and space vehicle research at SRM University AP. Understanding the fundamental physics of how these vehicles behave in challenging atmospheres will contribute a lot to the design of current and future space vehicles re-entering from space into earth and mars atmospheres. The project aims to develop methods that can capture high-resolution images (like a DSLR camera) of these flows using minimal computational resources.

Dr Satya Pramod Jammy, Associate Professor, Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, has received a total outlay of Rs. 38,61, 264/- from Department of Science and Technology (DST) Science and Engineering Research Board, Government of India, to work on the project titled “Wall effects in Shock wave boundary layer interactions”. Using the grant, state-of-the-art HPC computational facilities based on the exciting General Purpose Graphic Processing Units (GPGPU’s) will be set up to perform missiles and space vehicle research at SRM University AP. Understanding the fundamental physics of how these vehicles behave in challenging atmospheres will contribute a lot to the design of current and future space vehicles re-entering from space into earth and mars atmospheres. The project aims to develop methods that can capture high-resolution images (like a DSLR camera) of these flows using minimal computational resources.

Dr Jammy is an expert in multi-scale modelling of turbulent flows at high Mach numbers. He is also the lead developer of OpenSBLI, a free and open-source software (FOSS) distributed to the community for free. Dr Jammy and his group will focus on unravelling the concepts like engine unstart in SCRAMJETS, design of better aerodynamic control surfaces for re-entry.

- Published in Mechanical Engineering NEWS, News, Research News

P Mohan Aditya granted copyright for biodegradable Face Shield design

When the Covid-19 outbreak crippled the world, P Mohan Aditya, a 3rd-year Mechanical Engineering student from SRM University-AP, made an initiative of developing the highly useful face shield made from bio-degradable substances. He named it “Facial Shield 2.0”, as it was an improved version of the ordinary face shields. The innovative features added to it helped him to earn the copyright to his credit. On May 16, 2020, Aditya filed an application on the face shield design under the IPR (Intellectual Property Rights) with Indian Patent Office, located in Kolkata, India. In 2021, a copyright was granted for the” Face Shield for Humans” with a Design Application Number of 329364 – 001.

When the Covid-19 outbreak crippled the world, P Mohan Aditya, a 3rd-year Mechanical Engineering student from SRM University-AP, made an initiative of developing the highly useful face shield made from bio-degradable substances. He named it “Facial Shield 2.0”, as it was an improved version of the ordinary face shields. The innovative features added to it helped him to earn the copyright to his credit. On May 16, 2020, Aditya filed an application on the face shield design under the IPR (Intellectual Property Rights) with Indian Patent Office, located in Kolkata, India. In 2021, a copyright was granted for the” Face Shield for Humans” with a Design Application Number of 329364 – 001.

The face shield 2.0 serves as the outer defence to the mucous membranes (nose, eyes, and mouth) and comes with a transparent visor made of a thin layer of 175-micron reusable plastic and a highly durable headband made of 3-ply corrugated cardboard. The cardboard’s bursting strength is 16kg/sq.cm, which is quite durable yet lightweight. Due to the use of biodegradable materials, the price of a face shield is at an affordable cost of INR 15. The face shield 2.0, made with firm elastic, is adjustable and suitable for all head sizes for comfortable wear without hurting the head.

Shri Adimulapu Suresh, Hon’ble Minister of Education, Andhra Pradesh and Sri Nandigama Suresh, Hon’ble MP, appreciated the student’s efforts in the Secretariat’s premises. Aditya received high accolades from the guests present on his first successful invention. They also distributed face shields among state police officers, paramedics and other frontline workers deployed in the containment areas.

In a conversation with P Mohan Aditya, he says, “With an increasing environmental degradation, we should move to the eco-friendly alternatives to develop products/services. Therefore, I thought to develop face shields from reusable plastic and cardboard, which are easily degradable. After discovering a shortage in the supply of Personal Protective Equipment (PPE) globally, the idea struck my mind. Immediately I started researching on developing a piece of standard equipment to combat the Covid-19 pandemic. I am thankful to Mr Ravi, the attorney at SRM-AP, who supported me throughout the tough times by answering all doubts amidst challenging circumstances.”

Aditya’s invention turned out to be a successful project both for the University and the public. The leadership team of SRM University-AP – Dr P Sathyanarayanan, President, Prof V S Rao, Vice-Chancellor, and Prof D Narayana Rao, Pro-Vice-Chancellor expressed their happiness on Aditya’s success by congratulating him on developing the face shield and making use of eco-friendly technology.

Aditya’s invention turned out to be a successful project both for the University and the public. The leadership team of SRM University-AP – Dr P Sathyanarayanan, President, Prof V S Rao, Vice-Chancellor, and Prof D Narayana Rao, Pro-Vice-Chancellor expressed their happiness on Aditya’s success by congratulating him on developing the face shield and making use of eco-friendly technology.

Using the CAD software, Aditya designed the transparent visor of the face shield and fabricated the remaining headband with the CNC machine. The CAD model was used as the input to the CNC machine, Following the design, the CNC machine analysed and cut the cardboard and transparent sheet accordingly.

P Mohan Aditya’s another innovative design on “building block for bed” was applied for a copyright on 09-08-2020. The building block for bed is again an innovative work of making beds using reusable materials for COVID 19 patients. He and his team also successfully created an electric bicycle using a 24V 250Watt DC motor powered by a 12V and 12Ah battery as a team assignment. Aditya desires to be a successful engineer and creator of such inventions for the betterment of society.

- Published in Mechanical Engineering NEWS, News, Research News, Students Achievements

SRM University-AP collaborates with the American Society of Mechanical Engineers (ASME)

The Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, introduces the globally recognised American Society of Mechanical Engineers (ASME) membership programmes to its students.

The Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, introduces the globally recognised American Society of Mechanical Engineers (ASME) membership programmes to its students.

The American Society of Mechanical Engineers (ASME) is a non-profit establishment formed for the global engineers’ community that promotes collaboration, knowledge sharing, career enhancement, and skill development. ASME Student Chapter helps university engineering students develop their professional identity and provides essential engagement opportunities by offering access to a wide range of activities and resources such as membership, competitions, scholarships, student sections and much more.

The engineering curriculum is not restricted to the theoretical aspects but involves practical applications. The collaboration with ASME will help students of our university to find engineering-related job articles, online journals, webinars, and workshops on a single platform. Students will be exposed to niche career paths and opportunities across industries where they can apply their mechanical engineering education to address critical issues facing the globe. Students can get in touch with experienced professionals all around the world through the ASME mentoring programme and seek careers or any other type of guidance.

SRM University-AP collaborates with global organisations to promote international exposure of students. In collaboration with ASME, the Department of Mechanical Engineering will be organising webinars and workshops by eminent faculties of the institute, where they will share their experiences and knowledge with the participants. The programme aims to create extraordinary learning experiences for the students to carry out many activities under this umbrella and fulfil the expectations of ASME.

Dr Prakash Jadav, Associate Professor in the Department of Mechanical Engineering, will be acting as faculty adviser for this chapter which is headed by Tushar Sahu.

- Published in Collaborations, Departmental News, Mechanical Engineering NEWS, News

Mechanical Engineering graduate admitted into Northeastern University, Boston

Lankalapalli Pavan Sai from the undergraduate department of Mechanical Engineering at SRM University-AP, Andhra Pradesh, has secured an astounding admission to Northeastern University (NEU), Boston for his higher education. The Master’s in Engineering Management programme that he has enrolled in meets F-1 international student status requirements and is purely designed for the Core background (i.e. Mechanical, Electrical, and Civil Engineering) students. Pavan Sai had also qualified to work with the global L&T Technology Services company through the campus placement at SRM University-AP.

Lankalapalli Pavan Sai from the undergraduate department of Mechanical Engineering at SRM University-AP, Andhra Pradesh, has secured an astounding admission to Northeastern University (NEU), Boston for his higher education. The Master’s in Engineering Management programme that he has enrolled in meets F-1 international student status requirements and is purely designed for the Core background (i.e. Mechanical, Electrical, and Civil Engineering) students. Pavan Sai had also qualified to work with the global L&T Technology Services company through the campus placement at SRM University-AP.

According to Pavan Sai, NEU lies in the heart of Boston city which is one of the major hubs for startups and the University is known for its CO-OP program that gives hands-on experience in theoretical, quantitative, and analytical skills and tools. His decision to study abroad happened rather late though he qualified IELTS on time and has been preparing for GRE.

When he applied to NEU just two days before the deadline, the faculty and staff at SRM University-AP extended their full assistance to go by the application. “I cannot forget the assiduous support and mentorship of my Professors Dr Satya Pramod Jammy and Dr Venkata Nori from the Department of Mechanical Engineering”, says Pavan Sai. “I also want to thank SRM University-AP for helping me and providing me with opportunities”, he adds.

- Published in Mechanical Engineering NEWS, News, Students Achievements

Undergraduates bring off one more patent to SRM University-AP

Young researchers from Mechanical Engineering- S.K Hassan, M.Vijaya Bhargava, Jithin Peram, and Meghana Bonthu- have added one more laurel to SRM University-AP by inventing something novel! Under the supervision of faculty from the Department of Mechanical Engineering, the quartet have published a patent A Comprehensive Disinfection System during Pandemic for Personal Items and Protective Equipment(PPE) to Safeguard People.

Young researchers from Mechanical Engineering- S.K Hassan, M.Vijaya Bhargava, Jithin Peram, and Meghana Bonthu- have added one more laurel to SRM University-AP by inventing something novel! Under the supervision of faculty from the Department of Mechanical Engineering, the quartet have published a patent A Comprehensive Disinfection System during Pandemic for Personal Items and Protective Equipment(PPE) to Safeguard People.

The current Covid-19 pandemic has led to an enormous demand for gadgets/objects for personal protection. To prevent the spread of the virus which proliferates also through surface transmission, it is important to disinfect objects of common use. One of the ways suggested is to use a UV-C disinfecting box that is efficient and effective in deactivating the COVID-19 virus. The novelty of the product prototype is the use of a UVC transparent material (fused silica quartz glass tubes). This not only physically supports the objects to be disinfected but also improves the effectiveness of disinfection. The aluminium foil which the students have used, a UV reflecting material, was used as the inner lining of the box for effective utilization of the UVC light emitted by the UVC lamps. Care has been taken to prevent leakage of UVC radiation out of the system. COVID-19 virus can be inactivated in 5 minutes by UVC irradiation in this disinfection box.

This novel product can help in efficiently sanitizing normal household items such as mobile phones, keys, purses, grocery and also PPE kits (masks, gloves, visors etc.). This product is not only affordable but also makes disinfection faster. Moreover, the operational process is simple – open the door, place the objects, turn it on and then retrieve them sanitised within minutes.

“We are looking forward to taking up this UV Box to the next stage of implementation with a more compact and more efficient mechanism”, says the proud team behind the invention. “We are ready to undertake new projects and with the help and support from Dr Venkat Nori and other faculty members”, they added.

Link to patent document: https://ipindia.gov.in/writereaddata/Portal/IPOJournal/1_4971_1/Part-1.pdf

- Published in Departmental News, Mechanical Engineering NEWS, News, Students Achievements