The perfect match: How human skills and artificial intelligence can work together

- Published in Thought Leadership

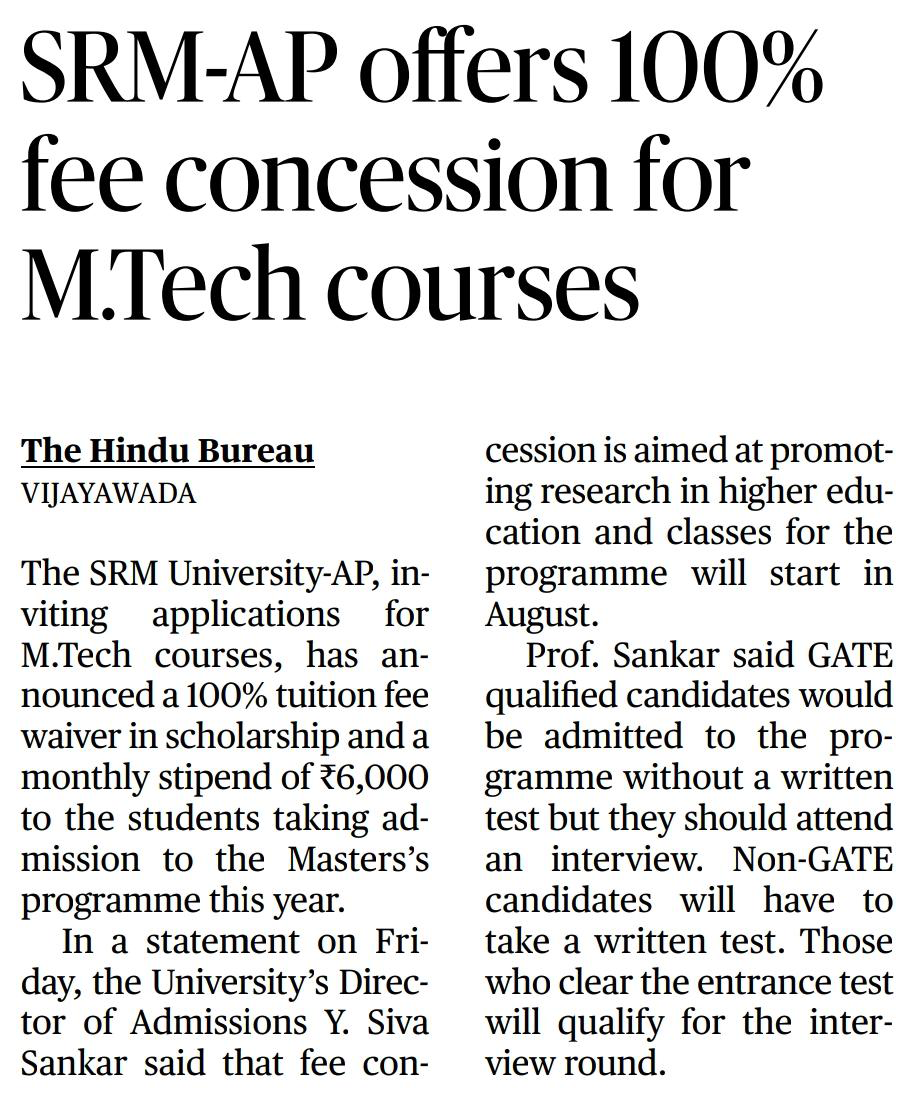

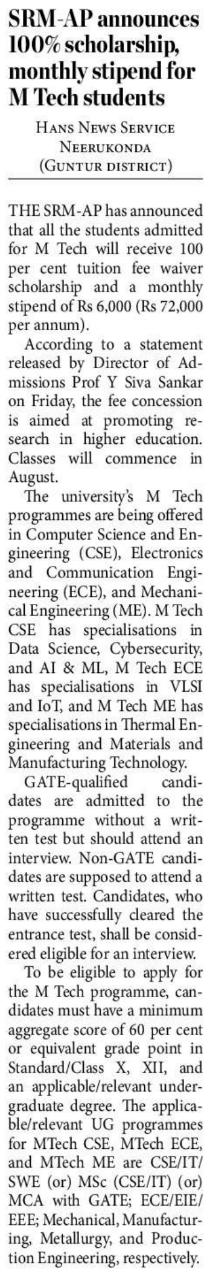

SRM University- AP invites applications for MTech Admission with a 100% Tuition Fee Waiver Scholarship and a Monthly Stipend

- Published in Newsroom

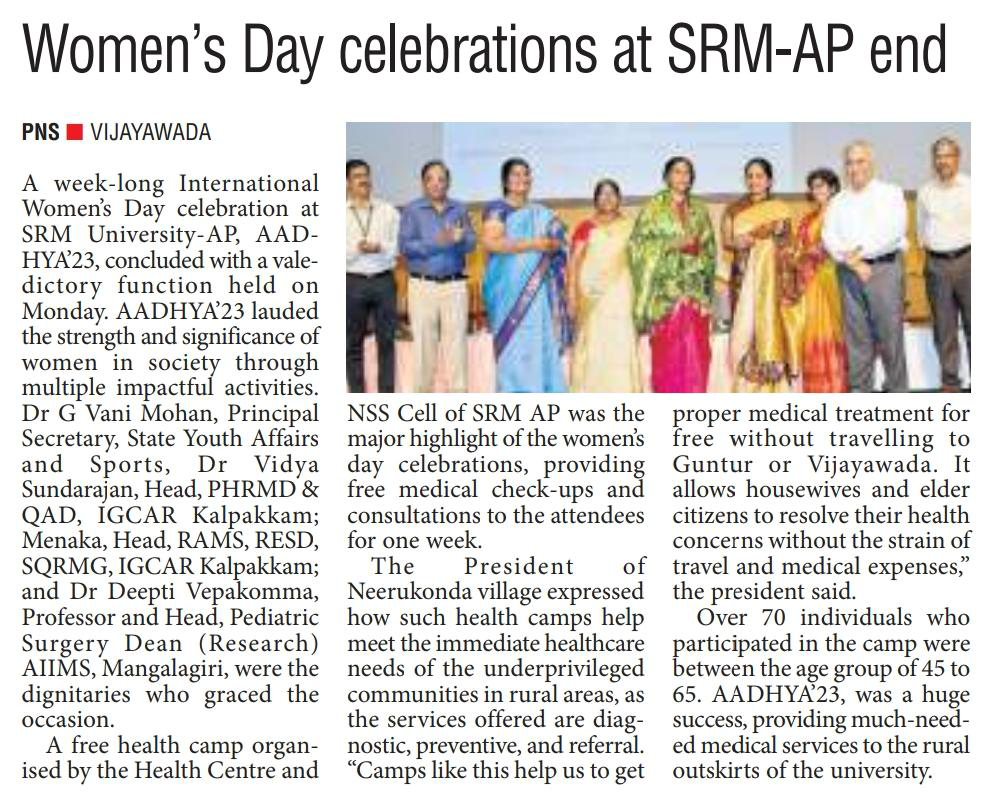

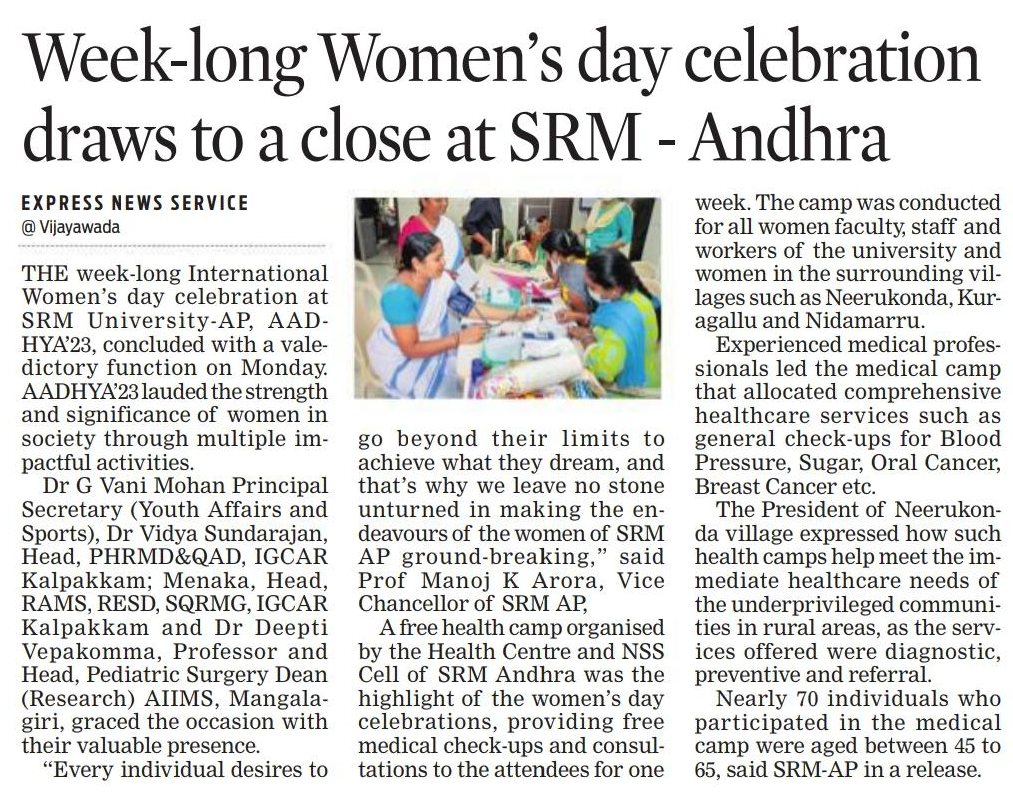

Meeting the Immediate Healthcare Needs of the Underprivileged: SRM University-AP Wraps the Week-long Free Health Camp

The Pioneer

The Hans India

The News Indian Express

Praja Sakthi

Surya

Vartha

Andhra Jyoti

Andhra Patrika

Andhra Prabha

Eenadu

- Published in Newsroom

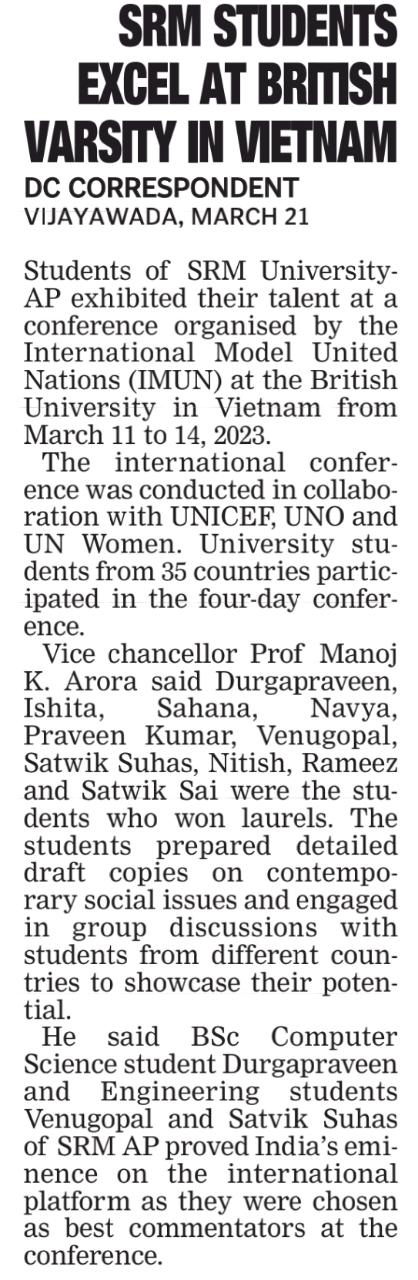

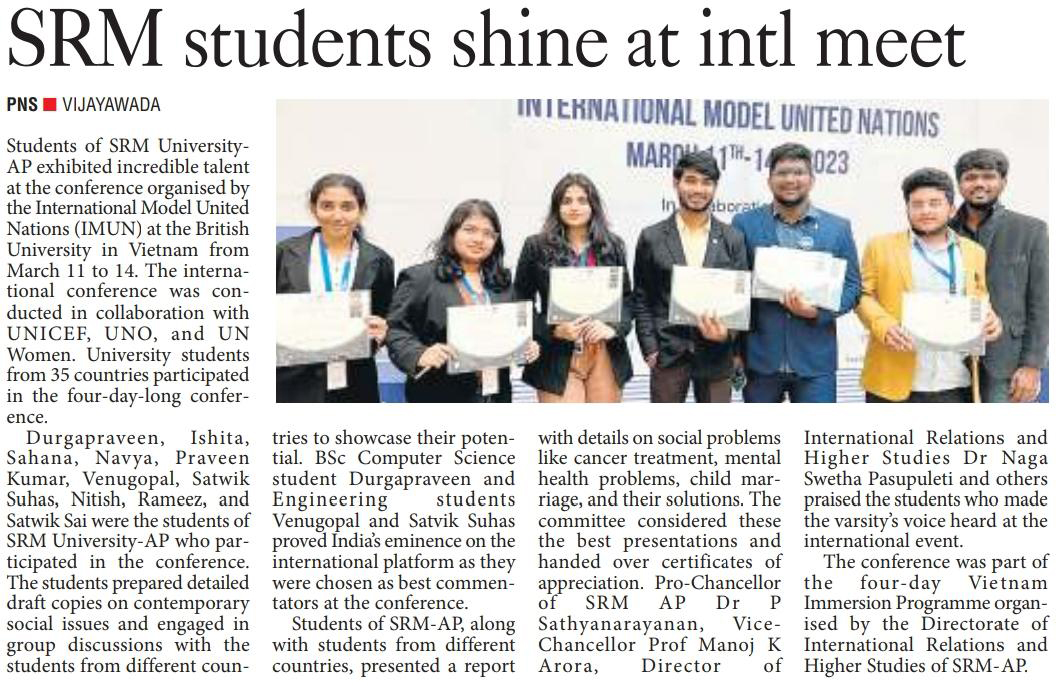

International Conference at the British University in Vietnam: Students of SRM University Get IMUN Appreciation for Being the ‘Best Commentators’

Deccan Chronicle

The Hindu

The Pioneer

News India Express

The Hans India

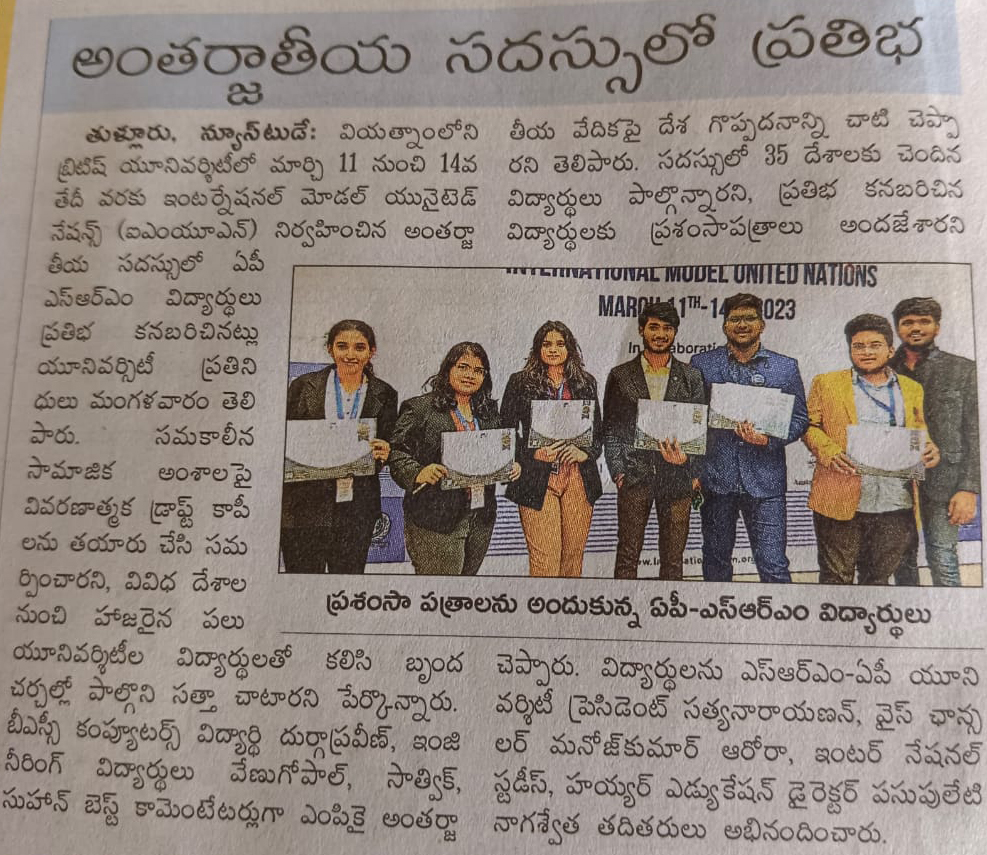

Eenadu

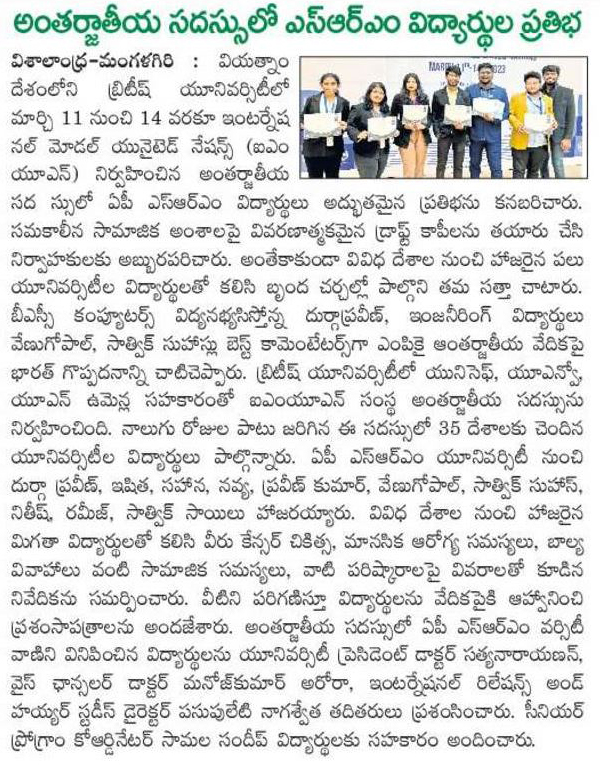

Visalandhra

Vartha

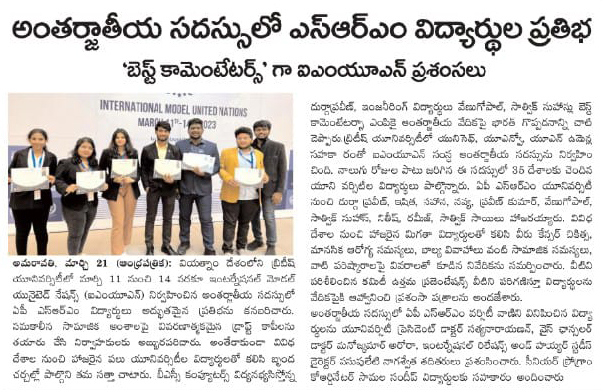

Surya

Andhra Patrika

- Published in Newsroom

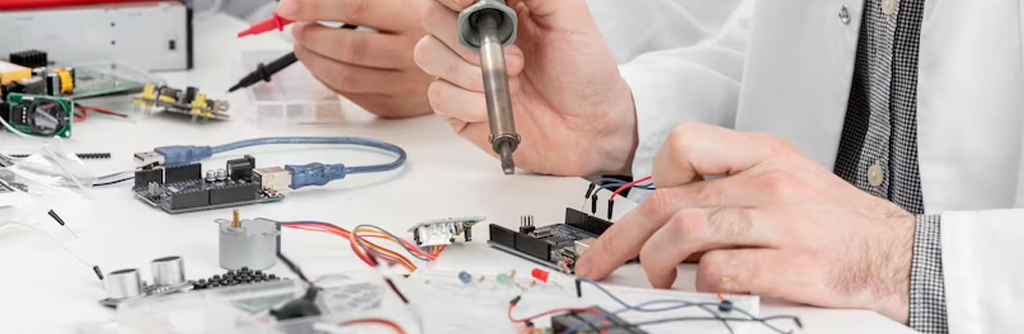

The Rise of Semiconductor Industry in India: Job Prospects for Engineers and Innovators

By Prof Y Siva Sankar

Professor of Practice, Department of Electronics and Communication Engineering

The time is right to hop onto the semiconductor bandwagon in India as the semiconductor industry in India is still in its early stages and poised for huge growth compared to some of the other major players in the global semiconductor market, such as the United States, South Korea, Japan, Taiwan, and China. The industry has been growing rapidly in recent years and is expected to play an increasingly important role in the global semiconductor ecosystem in the coming years.

According to a report by the India Electronics and Semiconductor Association (IESA), the Indian semiconductor industry was valued at approximately $36 billion in 2020. This includes the sales of integrated circuits (ICs), diodes, transistors, and other semiconductor products. The industry is expected to grow at a compound annual growth rate (CAGR) of around 22% between 2020 and 2025, reaching a value of $84 billion by 2025.

According to a report by Research and Markets, the global semiconductor market was valued at $464.1 billion in 2020 and is expected to reach $804.3 billion by 2026, growing at a CAGR of 9.3% between 2021 and 2026. The report highlights that the Asia-Pacific region, which includes India, is the largest market for semiconductors, accounting for over 50% of the global market share.

India’s semiconductor industry is expected to benefit from the global growth in demand for semiconductors, driven by the increasing adoption of technologies such as 5G, artificial intelligence, and the Internet of Things (IoT) in various industries. In addition, India is a major consumer of semiconductor products, but most of these products are imported. The Indian government has recognized the potential of the semiconductor industry and has taken several steps to promote its growth in the country.

Some of the key initiatives are:

- Make in India: The Make in India initiative, launched in 2014, aims to promote India as a global manufacturing hub by providing various incentives and reducing the regulatory burden on businesses. The initiative aims to increase the share of manufacturing in India’s GDP from 16% to 25% by 2025.

- National Policy on Electronics: The National Policy on Electronics (NPE) was launched in 2019 to promote the domestic manufacturing of electronic products and increase the value added in the electronics sector. The policy aims to create a conducive environment for the industry and attract foreign investment in the sector.

- Electronics Development Fund: The Electronics Development Fund (EDF) was set up in 2012 to financially support domestic companies involved in electronics design and manufacturing. The fund provides seed capital, venture capital, and debt financing to eligible companies.

- Modified Special Incentive Package Scheme: The Modified Special Incentive Package Scheme (M-SIPS) was launched in 2012 to provide capital subsidies to domestic companies to set up new electronics manufacturing units or expand existing ones. The scheme also includes reimbursement of central and state taxes and duties.

- Electronic Manufacturing Clusters: The government has set up Electronic Manufacturing Clusters (EMCs) across the country to provide world-class infrastructure and facilities to domestic and foreign companies for electronics manufacturing. The EMCs offer various incentives to eligible companies, such as tax exemptions, subsidies, and reimbursements.

Another significant step taken by the government is establishing a semiconductor wafer fab manufacturing facility in India. In 2020, the government announced the setting up of a Rs 6,900-crore ($941 million) semiconductor wafer fab manufacturing facility in Prayagraj, Uttar Pradesh. This facility is expected to boost the country’s semiconductor manufacturing capabilities and reduce its deep import dependence furthermore; several leading semiconductor companies have established their research and development (R&D) centres in India, taking advantage of the country’s vast talent pool and cost-effective workforce. These R&D centres are involved in developing cutting-edge semiconductor technologies and designing chips for various applications. These companies include Intel, Qualcomm, Samsung, Texas Instruments, and Broadcom.

- Published in Engineering

Opportunities and Career Paths in the Semiconductor Industry

According to a report by the India Semiconductor Association, the semiconductor industry in India is expected to create 1.75-2 million direct and indirect jobs by 2025. The report also stated that the industry had created 400,000 direct and indirect employment as of 2018.

The report highlighted that the demand for skilled professionals in the semiconductor industry is expected to increase across various job roles and functions, including research and development, design, manufacturing, testing, quality control, and sales and marketing.

In terms of salaries, the semiconductor industry in India offers competitive remuneration packages to skilled professionals. The average salary for a design engineer in the semiconductor industry in India is around INR 9-10 lakhs per annum, while the salary for a project manager can range from INR 15-25 lakhs per annum. Salaries for senior-level positions, such as director or vice president, can range from INR 50-100 lakhs per annum.

![]()

The semiconductor industry in India also offers good career growth opportunities, with skilled professionals able to progress to senior-level positions within a few years. The industry sector provides opportunities for professionals to work on cutting-edge technologies and contribute to developing innovative products.

The semiconductor industry is large and diverse, with many different job roles and career paths available. Some of the most common job roles in the semiconductor industry include the following:

1. Semiconductor Process Engineer:

A Semiconductor Process Engineer is responsible for designing and developing processes for manufacturing semiconductor devices such as integrated circuits, microprocessors, and memory chips. They work closely with other engineers and technicians to optimize production processes and ensure that the final products meet quality and performance standards.

The job role of a Semiconductor Process Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and improving semiconductor manufacturing processes and equipment

- Conducting experiments and analyzing data to identify process improvements

- Designing and implementing process control systems to monitor and optimize production

- Troubleshooting and resolving process-related issues to minimize downtime and maintain production schedules

Some of the skills required for a Semiconductor Process Engineer include:

- Strong understanding of semiconductor manufacturing processes and equipment

- Proficiency in data analysis and statistical process control

- Familiarity with CAD tools, modeling software, and simulation techniques

- Experience in process development, optimization, and validation

Overall, a Semiconductor Process Engineer ensures the production processes are optimized for maximum efficiency and high-quality products.

- Published in Engineering

Semiconductor Design Engineer

![]()

2. Semiconductor Design Engineer

A Semiconductor Design Engineer is responsible for designing and developing semiconductor components and systems such as microprocessors, memory chips, and integrated circuits. They work closely with other engineers, including process engineers, to ensure their designs can be manufactured using existing or new production processes.

The job role of a Semiconductor Design Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing semiconductor design methodologies, processes, and standards

- Designing and testing semiconductor components and systems using CAD tools and simulation software

- Collaborating with cross-functional teams, including process engineers, testing engineers, and project managers, to ensure successful design and product development

- Conducting feasibility studies and analysing technical requirements to guide design decisions

- Ensuring that designs meet performance, power, and cost targets while adhering to quality and safety standards

- Preparing and reviewing design documentation, including schematics, layouts, and test plans

- Troubleshooting and resolving design-related issues to ensure successful product development and release

Some of the skills required for a Semiconductor Design Engineer include:

- Strong understanding of semiconductor design methodologies, processes, and standards

- Proficiency in CAD tools and simulation software for designing semiconductor components and systems

- Familiarity with semiconductor manufacturing processes and their impact on design

- Experience in designing and testing complex semiconductor systems

Overall, a Semiconductor Design Engineer ensures that semiconductor components and systems are designed to meet performance, cost, and quality targets while adhering to safety and regulatory standards.

- Published in Engineering

Semiconductor Test Engineer

3. Semiconductor Test Engineer

![]()

A Semiconductor Test Engineer is responsible for designing and developing testing processes and systems for semiconductor devices such as microprocessors, memory chips, and integrated circuits. They work closely with other engineers, including design and process engineers, to ensure the testing processes are optimized for the specific device.

The job role of a Semiconductor Test Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing test methodologies, processes, and standards for semiconductor devices

- Designing and developing test hardware and software for semiconductor testing systems

- Collaborating with cross-functional teams, including design, process, and packaging engineers, to ensure successful product testing

- Conducting feasibility studies and analysing technical requirements to guide testing process development

- Ensuring that testing processes meet performance, power, and cost targets while adhering to quality and safety standards

- Preparing and reviewing test documentation, including test plans and test reports

- Troubleshooting and resolving test-related issues to ensure successful product testing and release

Some of the skills required for a Semiconductor Test Engineer include:

- Strong understanding of semiconductor testing methodologies, processes, and standards

- Proficiency in testing hardware and software for semiconductor devices

- Familiarity with semiconductor manufacturing processes and their impact on testing

- Experience in designing and developing testing processes and systems for semiconductor devices

Overall, a Semiconductor Test Engineer ensures that semiconductor devices are tested and validated to meet performance, cost, and quality targets while adhering to safety and regulatory standards.

- Published in Engineering

Design for Testability (DFT) Engineer

4. Design for Testability (DFT) Engineer

A DFT (Design for Testability) Engineer is responsible for designing and implementing testability features in semiconductor devices such as microprocessors, memory chips, and integrated circuits. They work closely with other engineers, including design, test, and manufacturing engineers, to ensure the device can be efficiently tested during manufacturing.

The job role of a DFT Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing testability features in semiconductor device designs

- Collaborating with design and test engineers to ensure that the device can be efficiently tested during the manufacturing process

- Analysing and optimising design for testability, including scan chain insertion and boundary scan implementation

- Creating and reviewing test plans and test coverage reports

- Designing and implementing functional test vectors and test programs for the device

- Developing and implementing fault models for the device to improve test coverage

- Troubleshooting and resolving DFT-related issues to ensure successful manufacturing and product release

Some of the skills required for a DFT Engineer include:

- Strong understanding of DFT methodologies, processes, and standards

- Proficiency in DFT tools and software for semiconductor devices

- Familiarity with semiconductor manufacturing processes and their impact on DFT

- Experience in designing and implementing DFT features in semiconductor device designs

Overall, a DFT Engineer ensures that semiconductors are designed with the necessary testability features to improve manufacturing efficiency and product quality while adhering to safety and regulatory standards.

- Published in Engineering

Physical Design (PD) Engineer

5. Physical Design (PD) Engineer

A Physical Design Engineer is responsible for designing and implementing the physical layout of semiconductor devices such as microprocessors, memory chips, and integrated circuits. They work closely with other engineers, including design, verification, and manufacturing engineers, to ensure that the device is optimised for performance, power, and manufacturability.

The job role of a Physical Design Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Designing and implementing the physical layout of semiconductor devices using tools such as Cadence, Synopsys, and Mentor Graphics

- Collaborating with design, verification, and manufacturing engineers to optimise the device for performance, power, and manufacturability

- Analysing and optimising the device for timing, power, noise, and thermal characteristics

- Creating and reviewing design rules and design constraints

- Developing and implementing design methodologies and flow to improve design efficiency and quality

- Preparing and reviewing design documentation, including floor plans, power grid, and package designs

- Troubleshooting and resolving physical design-related issues to ensure successful manufacturing and product release.

Some of the skills required for a Physical Design Engineer include:

- Strong understanding of physical design methodologies, processes, and standards

- Proficiency in physical design tools and software such as Cadence, Synopsys, and Mentor Graphics

- Familiarity with semiconductor manufacturing processes and their impact on physical design

- Experience in designing and implementing physical layouts of semiconductor devices

Overall, a Physical Design Engineer ensures that semiconductor devices are optimised for performance, power, and manufacturability while adhering to safety and regulatory standards.

- Published in Engineering