All Management Events

- Budget 2024 Boosts Entrepreneurship: Tarun Scheme Expansion and Fiscal Discipline July 26, 2024

Dainik Savera

Continue reading →

- Dr Sachchidanand July 26, 2024

- Dimpal Janu July 26, 2024

- 2024 Budget: A Tour de Force Igniting Indian MSME’s Economic Renaissance July 26, 2024

Deccan Business

Continue reading →

1Money Mania

Republic News India

Wow Entrepreneur

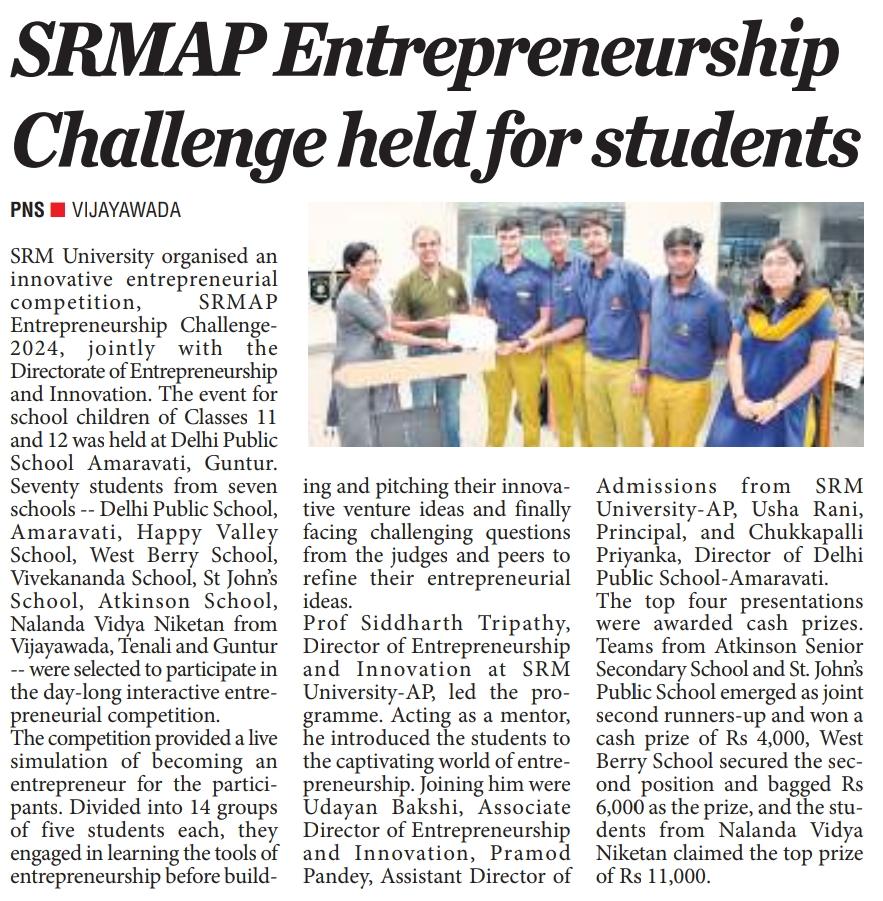

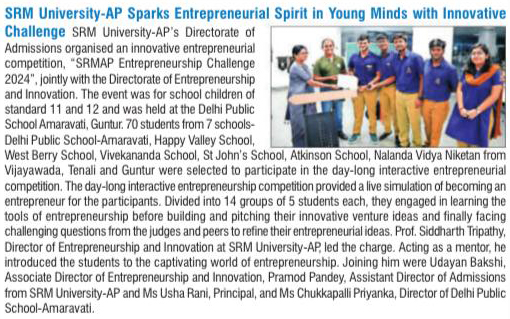

- SRM University-AP Sparks Entrepreneurial Spirit in Young Minds with Innovative Challenge July 25, 2024

- A review of Union of Budget 2024 towards “Energy Sector” July 25, 2024

The Hans India

Continue reading →

Republic News India

The Indian Bulletin

RD Times

Republic News India

- Dr Dwivedy and Dr Nagasai Upgrade CMT Technology July 25, 2024

Dr Maheshwar Dwivedy, Associate Dean of Practice School, and Associate Professor, at the Department of Mechanical Engineering, SRM University-AP in collaboration with his post-doctoral scholar, Dr B Prasanna Nagasai, have joined forces to combine artificial intelligence with Cold Metal Transfer (CMT) Technology. Their research paper, “Cold Metal Transfer Technology – A Review of Recent Research Developments,” featured in the Q1 journal, Results in Engineering promises to make a significant impact on automobile, aerospace, oil and gas manufacturing industries, and that’s not all the research will also generate employment opportunities, and empower engineers to deliver enhanced services.

Abstract:

Cold Metal Transfer (CMT) technology has emerged as a promising welding technique, offering numerous advantages such as reduced heat input, minimal spatter, and enhanced control over the welding process. This paper provides a comprehensive review of recent research developments in CMT technology, focusing on its history, variants, recent advancements, and future perspectives. Initially, the paper traces the historical development of CMT welding, highlighting its evolution and the introduction of various CMT variants with distinct characteristics and applications. Recent studies have focused on optimising CMT process parameters to improve weld quality and productivity, leading to advancements in parameter control, arc stability, and wire-feeding mechanisms. Additionally, research has explored the microstructural evolution and mechanical properties of CMT-welded joints for both similar and dissimilar metals, providing insights into material compatibility, joint design, and performance under various conditions. Specific applications such as Laser-CMT hybrid welding, CMT cladding, CMT wire arc additive manufacturing, and CMT welding for repair across various materials are examined, demonstrating the versatility of CMT technology. This review also addresses the challenges and methodologies for defect reduction in CMT welding, along with recommendations for best practices. Furthermore, the paper discusses the integration of artificial intelligence in CMT welding, exploring opportunities for enhanced weld quality, economic, and social implications, and future research directions.

Practical and Social Implications:

The practical implementation of this research on Cold Metal Transfer (CMT) technology can significantly impact various industries, such as automotive, aerospace, oil and gas, and manufacturing. By optimising CMT welding parameters and integrating advanced features like arc length control and waveform modulation, industries can achieve higher weld quality, reduce defects, and enhance productivity. This can lead to more reliable and efficient manufacturing processes, resulting in cost savings and improved product performance. Social implications associated with this research include the potential for increased job opportunities and skill development in the welding and manufacturing sectors. As industries adopt advanced CMT technology, there will be a growing demand for skilled workers trained in these techniques. Additionally, improved welding quality and reduced defects can lead to safer and more durable products, enhancing overall public safety and satisfaction. The integration of artificial intelligence in CMT welding also opens up new avenues for innovation and technological advancements, fostering a culture of continuous improvement and progress in the manufacturing industry.

Collaborations:

Dr V Balasubramanian,

Professor & Director,

Centre for Materials Joining & Research (CEMAJOR)

Annamalai University, Annamalai Nagar-608002, Tamilnadu.Dr P Snehalatha,

Associate Professor & Head

Department of Mechanical Engineering,

Sri Padmavathi Mahila Visvavidyalam, Tirupati, Andhra Pradesh-517502, India.Future Research Plans:

The upcoming work will concentrate on creating Functionally Graded Materials (FGMs) through Wire-Arc Additive Manufacturing (WAAM) by merging nickel and stainless steel. The goal of this research is to leverage the distinct properties of each metal to develop components suited for specialised high-performance applications. The primary challenges involve optimizing the interfaces between materials, refining the deposition processes, and ensuring strong structural integrity throughout the manufacturing process.

The link to the article: https://doi.org/10.1016/j.rineng.2024.102423

Continue reading → - “Nano Jatha”: A Pathway to Nanoscience and Technology July 25, 2024

As part of the 13th edition of the Bengaluru India Nano 2024, heralded by Bharat Ratna recipient and renowned chemist Prof. C N R Rao, SRM University-AP hosted “Nano Jatha“, an intensive science outreach programme, catering to educate undergraduate graduates on the emerging trends of nanotechnology, on July 20, 2024. The Nano Jatha programme organised, aimed to raise awareness on nanoscience and technology through technical presentations by expert scientists and a distinctive live experiment demonstration of nano kits focused on showcasing nanoscience ideas.

The event featured two expert talks by eminent dignitaries. Prof. B L V Prasad, Director-Centre for Nano and Soft Matter Sciences (CeNS), Department of Science and Technology, Govt. of India, also serving as the Nodal Officer for organising Nano Jatha events, delivered a session on the introduction to nanoscience and technology. “Nanoscience and technology are often foretold as the technology of the future. This multidimensional technology will revolutionise our understanding of every natural phenomenon and every aspect of human life,” remarked Prof. Prasad in his session.

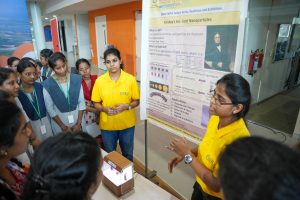

Prof. C P Rao, Senior Professor at the Department of Chemistry, presented the second expert talk on the applications of nanomaterials. The session delved into the properties of covalent molecules and its assemblage leading to cutting-edge technology. The programme also featured an exhibition were experiments on Gold nanoparticle; Galvanization reaction between metals; Piezoelectric pavement for futuristic applications; Humidity sensors for real-world applications and many more were displayed.

Prof. C V Tomy, Dean-School of Engineering & Sciences and Dr Pardha Saradhi Maram, Head-Department of Chemistry, emphasised that the Nano Jatha exemplified the university’s commitment to hands-on learning in science, specifically nanotechnology.They commented that the Department of Chemistry is dedicated to fostering scientific knowledge and igniting passion for chemistry among students and educators alike and will continue to organise events like Nano Jatha, conferences, workshops, and Faculty Development Programmes to achieve the same.

Over 300 students from 7 regional colleges in Andhra Pradesh participated in the programme, displaying their zeal in the discussions and nano kit demonstrations. The event was well executed benefitting the student community significantly in understanding various emerging fields in science and technology.

Continue reading → - Dr Jaidev Kaushik July 24, 2024

- Dr Jyotibhusan Padhi July 24, 2024