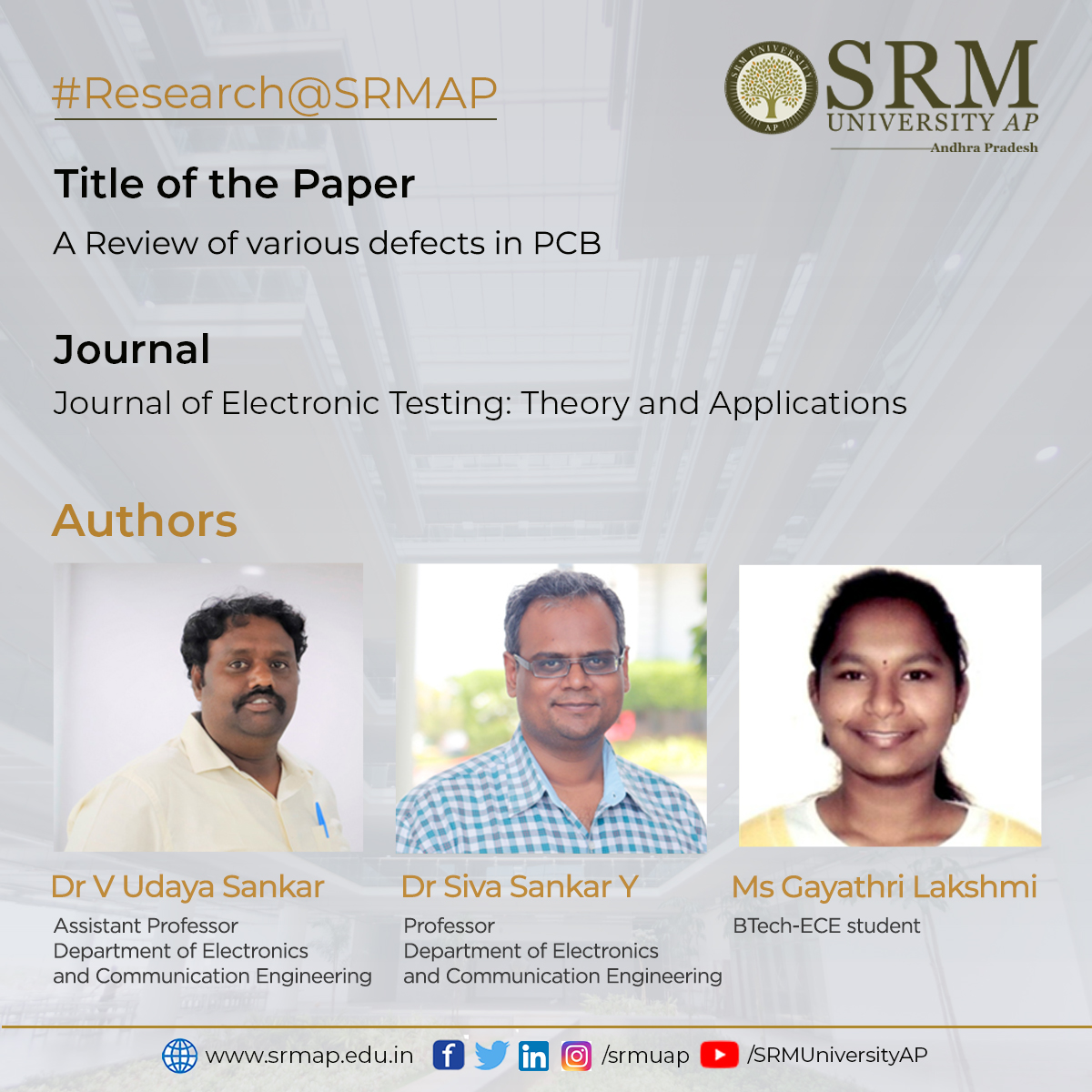

Research at the Department of Electronics and Communication Engineering is currently developing defect detection algorithms. Assistant Professor Dr V Udaya Sankar, Professor Dr Yellampalli Siva Sankar, and their BTech student Ms Gayathri Lakshmi have published a paper, A Review of various defects in PCB, in the Journal of Electronic Testing: Theory and Applications with an impact factor of 0.795.

Research at the Department of Electronics and Communication Engineering is currently developing defect detection algorithms. Assistant Professor Dr V Udaya Sankar, Professor Dr Yellampalli Siva Sankar, and their BTech student Ms Gayathri Lakshmi have published a paper, A Review of various defects in PCB, in the Journal of Electronic Testing: Theory and Applications with an impact factor of 0.795.

Abstract

Printed Circuit Boards (PCBs) are the building blocks for all electronic products. Fabrication of a PCB involves various mechanical and chemical processes. As obtaining accuracy in the mechanical and chemical processes is very difficult, various defects/faults are formed during PCBs fabrication. These fabrication defects lead to performance degradation of electronic products. This paper describes multiple defects present in PCBs under the Through-hole and SMD categories. To understand the frequency of occurrence and reason for defects in both manual and machine, PCB fabrication data was collected and analysed from April 2017 to July 2020 as a part of industry collaboration.

The research is a review done on the defects present in PCB. Researchers surveyed various papers on PCB defects and their detection. Based on the literature review and information obtained from Efftronics systems Pvt. Ltd, they classified the defects, gave a detailed explanation for each, and provided some analysis of their occurrences.

While doing the literature review, researchers observed that no paper mentioned all the defects that can occur in the case of PCB fabrication. For this reason, they came up with this paper which provides detailed information regarding the defects. Information is also obtained from the industry. Comparing the defects can help focus on the critical defects for future research on defect detection methodology.

The project is done in collaboration with Efftronics Systems Pvt. Ltd. Through the partnership, the company supported sharing images, insights information related to defects and involved in discussions. Also, the company allowed visiting their premises to understand more about PCB defects. Researchers look forward to creating a prototype that detects all the defects mentioned in this paper for a given PCB.