Verification Engineer

6. Verification Engineer

Verification Engineers are responsible for verifying and validating electronic hardware and software design functionality. They ensure that the design meets the specified requirements, is robust, and meets the required quality standards. Verification engineers work closely with other engineers, including design, validation, and manufacturing engineers, to ensure that the product meets the required standards and is ready for release.

The job role of a Verification Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing verification plans and test benches for electronic hardware and software designs

- Collaborating with design and validation engineers to ensure that the product meets the specified requirements and standards

- Creating and reviewing design verification documentation, including test plans, test cases, and test coverage reports

- Designing and implementing functional and non-functional tests for the product

- Developing and implementing fault models and stress tests for the product

- Troubleshooting and resolving verification-related issues to ensure successful product release

Some of the skills required for a Verification Engineer include:

- Strong understanding of verification methodologies, processes, and standards

- Proficiency in verification tools and software for electronic hardware and software designs such as SystemVerilog, UVM, and Verilog

- Familiarity with manufacturing processes and their impact on verification

- Experience in designing and implementing verification plans and test benches for electronic hardware and software designs

Steps to master the skillset required for Verification

- Learn the basics of digital electronics: Before you dive into VLSI verification, you need to have a solid foundation in digital electronics. You should be familiar with Boolean algebra, logic gates, and digital circuits.

- Familiarize yourself with VLSI design: It is essential to understand the design process of VLSI circuits. You should learn about the different types of design methodologies, design flows, and tools used in VLSI design.

- Study verification methodologies: Verification methodologies provide a systematic approach to verifying a design’s functionality. You should learn about various verification methodologies such as UVM (Universal Verification Methodology), OVM (Open Verification Methodology), and VMM (Verification Methodology Manual).

- Practice coding: VLSI verification requires coding skills. You should learn programming languages such as SystemVerilog and C++.

- Get hands-on experience: VLSI verification requires practical experience. You can get hands-on experience by working on projects, internships, or online courses.

Best websites to learn Verification

- Verification Academy: Verification Academy is a comprehensive online resource for learning VLSI verification. It offers free online courses, webinars, and technical papers on verification methodologies, tools, and techniques.

- VLSI Encyclopedia: VLSI Encyclopedia is an online resource for learning VLSI design and verification. It provides a wealth of information on topics such as digital design, verification, analog design, and testing.

- ChipVerify: ChipVerify is a website that offers free online courses on SystemVerilog, UVM, and VLSI verification. It also provides a platform for users to practice coding and learn through practical examples.

- Udemy: Udemy is an online learning platform that offers several courses on VLSI verification. These courses cover topics such as SystemVerilog, UVM, and verification methodologies.

- Coursera: Coursera is another online learning platform that offers courses on VLSI verification. These courses are developed by leading universities and cover topics such as digital circuits, VLSI design, and verification.

- YouTube: YouTube has several channels that offer tutorials and lectures on VLSI verification. Some popular channels include VerificationGentleman, Doulos, and Synopsys

Websites where we can practice Verification

- EDA Playground: EDA Playground is a free online platform that allows you to practice coding and simulation of digital circuits. You can use EDA Playground to practice coding in SystemVerilog and run simulations using various simulators.

- ChipVerify: ChipVerify offers a free online platform for practising coding and simulation of digital circuits. You can practice coding in SystemVerilog and run simulations using UVM-based testbenches.

- VLSI Encyclopedia: VLSI Encyclopedia offers a free online platform for practising coding and simulation of digital circuits. You can use the platform to practice coding in Verilog, VHDL, and SystemVerilog.

- Questa Verification Community: Questa Verification Community is a free online community for practising VLSI verification. You can use the community to access resources, tutorials, and webinars on verification methodologies and tools.

- Synopsys VCS Community Edition: Synopsys VCS Community Edition is a free simulator that you can use to practice VLSI verification. You can use the simulator to run simulations on your Verilog or SystemVerilog code.

Best books to refer to

- SystemVerilog for Verification: A Guide to Learning the Testbench Language Features, Third Edition, by Chris Spear and Greg Tumbush: This book provides a comprehensive introduction to SystemVerilog and its use in verification. It covers topics such as classes, constrained-random testing, and functional coverage.

- UVM: A Guide to the Universal Verification Methodology, Second Edition, by Ray Salemi: This book provides a comprehensive introduction to the Universal Verification Methodology (UVM) and its use in verification. It covers topics such as UVM classes, transactions, and sequences.

- Verification Methodology Manual for SystemVerilog, by Janick Bergeron, Eduard Cerny, Alan Hunter, and Andy Nightingale: This book provides a detailed description of the Verification Methodology Manual (VMM) for SystemVerilog. It covers topics such as testbenches, sequences, and scoreboards.

- Practical UVM, by Ray Salemi: This book provides a practical introduction to the Universal Verification Methodology (UVM) and its use in verification. It covers topics such as UVM testbenches, sequences, and coverage.

- Verification Methodology Cookbook, by Janick Bergeron: This book provides a practical guide to verification methodology. It covers topics such as verification planning, testbenches, and coverage.

- Digital Design and Verification with Verilog and SystemVerilog, by Frank Vahid and Roman Lysecky: This book provides a comprehensive introduction to digital design and verification using Verilog and SystemVerilog. It covers topics such as combinational and sequential logic, simulation, and synthesis.

Overall, Verification Engineers play a critical role in ensuring the quality of electronic hardware and software designs, ensuring that products meet the required standards and are ready for release.

- Published in Engineering

Front End Design Engineer

7. Front End Design Engineer

A Front End Design Engineer is responsible for developing and implementing electronic circuits and systems, from conception to final product release. They work closely with other engineers, including Verification, Physical Design, and Test Engineers, to ensure the design meets the specified requirements and standards.

The job roles of a Front End Design Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Designing and developing electronic circuits and systems, including microprocessors, memory chips, and integrated circuits, using languages such as Verilog and VHDL

- Collaborating with Verification Engineers to ensure that the design meets the specified requirements and standards

- Creating and reviewing design documentation, including specifications, block diagrams, and schematics

- Optimizing the design for timing, power, noise, and thermal characteristics

- Conducting design simulations and analysis to validate the design

- Providing guidance and support to the Physical Design Engineers to ensure that the design can be manufactured efficiently

Some of the skills required for a Front End Design Engineer include:

- Strong understanding of electronic design methodologies, processes, and standards

- Proficiency in design languages such as Verilog and VHDL

- Familiarity with design tools such as Cadence, Synopsys, and Mentor Graphics

- Experience in designing and developing electronic circuits and systems

Overall, a Front End Design Engineer ensures that electronic circuits and systems are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards.

- Published in Engineering

CAD Engineer

8. CAD Engineer

A CAD Design Engineer in the VLSI (Very Large Scale Integration) industry is responsible for designing and testing electronic circuits and systems using CAD software. They work closely with other engineers, including Physical Design, Verification, and Circuit Design Engineers, to ensure the design meets the specified requirements and standards.

The job roles of a CAD Design Engineer in the VLSI industry can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing CAD tools and methodologies for electronic circuit and system design

- Collaborating with Physical Design Engineers to ensure that the design is optimised for timing, power, and area

- Creating and reviewing design documentation, including specifications, block diagrams, and schematics

- Conducting design simulations and analysis to validate the design

- Providing guidance and support to the Circuit Design Engineers to ensure that the design meets the specified requirements and standards

- Staying up-to-date with new technologies, materials, and design tools to continually improve design processes and product quality.

Some of the skills required for a CAD Design Engineer in the VLSI industry include:

- Strong understanding of electronic design methodologies, processes, and standards

- Proficiency in CAD software for electronic circuit and system design, such as Cadence, Synopsys, and Mentor Graphics

- Familiarity with semiconductor manufacturing processes and their impact on design

- Experience in designing and developing electronic circuits and systems using CAD software

Overall, a CAD Design Engineer in the VLSI industry plays a critical role in ensuring that electronic circuits and systems are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards.

- Published in Engineering

Analog Design Engineer

9. Analog Design Engineer

An Analog Design Engineer is responsible for designing and testing analog circuits and systems, including amplifiers, filters, and data converters. They work closely with other engineers, including Digital Design, Verification, and Layout Engineers, to ensure that the analog circuits and systems meet the specified requirements and standards.

The job roles of an Analog Design Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing analog circuit and system design methodologies and processes

- Collaborating with Digital Design Engineers to ensure that the analog and digital circuits and systems are integrated properly

- Designing and testing analog circuits and systems, including amplifiers, filters, and data converters

- Conducting design simulations and analysis to validate the design

- Developing and reviewing design documentation, including specifications, block diagrams, and schematics

- Providing guidance and support to Layout Engineers to ensure that the design is optimised for area and manufacturability

- Staying up-to-date with new technologies, materials, and design tools to continually improve design processes and product quality.

Some of the skills required for an Analog Design Engineer include:

- Strong understanding of analog circuit and system design methodologies, processes, and standards

- Proficiency in simulation tools such as SPICE and MATLAB

- Experience in designing and developing analog circuits and systems, including amplifiers, filters, and data converters

- Familiarity with semiconductor manufacturing processes and their impact on design

Overall, an Analog Design Engineer plays a critical role in ensuring that analog circuits and systems are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards.

- Published in Engineering

Analog Layout Engineer

10. Analog Layout Engineer

An Analog Layout Engineer is responsible for designing and optimising the layout of analog circuits and systems. They work closely with other engineers, including Analog Design, Digital Design, and Verification Engineers, to ensure that the structure meets the specified requirements and standards.

The job roles of an Analog Layout Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing layout methodologies and processes for analog circuits and systems

- Collaborating with Analog and Digital Design Engineers to ensure that the layout is optimised for area and manufacturability while meeting the specified electrical requirements

- Designing and optimising the physical layout of analog circuits and systems, including floor planning, power routing, and signal routing

- Conducting layout verification and analysis to ensure that the design meets the specified requirements and standards

- Developing and reviewing layout documentation, including GDSII files, design rule checks, and layout-versus-schematic (LVS) reports

- Providing guidance and support to other engineers to ensure that the layout is optimised for area, performance, and manufacturability

Some of the skills required for an Analog Layout Engineer include:

- Strong understanding of analog circuit and system design methodologies, processes, and standards

- Proficiency in layout tools such as Virtuoso, Calibre, and Assura

- Experience in designing and optimising the physical layout of analog circuits and systems, including floor planning, power routing, and signal routing

- Familiarity with semiconductor manufacturing processes and their impact on layout design

Overall, an Analog Layout Engineer is critical in ensuring that analog circuits and systems are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards.

- Published in Engineering

RF Design Engineer

11. RF Design Engineer

An RF (Radio Frequency) Design Engineer is responsible for designing and testing components and systems operating at radio frequencies, typically between 3 kHz and 300 GHz. They work closely with other engineers, including Analog Design, Digital Design, and Layout Engineers, to ensure that the RF components and systems meet the specified requirements and standards.

The job roles of an RF Design Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Designing and testing RF components and systems, including amplifiers, filters, mixers, and oscillators

- Conducting RF simulations and analysis to validate the design

- Collaborating with Analog and Digital Design Engineers to ensure that the RF components and systems are integrated properly

- Developing and reviewing design documentation, including specifications, block diagrams, and schematics

- Providing guidance and support to Layout Engineers to ensure that the RF design is optimised for area and manufacturability

Some of the skills required for an RF Design Engineer include:

- Strong understanding of RF circuit and system design methodologies, processes, and standards

- Proficiency in simulation tools such as ADS, HFSS, and CST

- Experience in designing and developing RF components and systems, including amplifiers, filters, mixers, and oscillators

- Familiarity with RF semiconductor manufacturing processes and their impact on design

- Knowledge of electromagnetic theory and transmission line theory

Overall, an RF Design Engineer is critical in ensuring that RF components and systems are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards.

- Published in Engineering

Product Engineer

12. Product Engineer

A VLSI (Very Large Scale Integration) Product Engineer manages the life cycle of VLSI products, from design to release and maintenance. They work closely with other engineers, including Design, Layout, Test, and Quality Engineers, to ensure that the VLSI products meet the specified requirements and standards.

The job roles of a VLSI Product Engineer can vary depending on the specific industry and company they work for, but generally, their duties include:

- Developing and implementing product strategies, including market analysis, product positioning, and pricing

- Collaborating with Design, Layout, Test, and Quality Engineers to ensure that the VLSI products meet the specified requirements and standards

- Managing the product life cycle, from design to release and maintenance

- Conducting product validation and analysis to ensure that the product meets the specified requirements and standards

- Developing and reviewing product documentation, including data sheets, application notes, and user manuals

- Providing guidance and support to other engineers to ensure that the product is optimised for performance, manufacturability, and quality

- Staying up to date with new technologies, market trends, and customer requirements to continually improve product quality and competitiveness.

Some of the skills required for a VLSI Product Engineer include:

- Strong understanding of VLSI design methodologies, processes, and standards

- Knowledge of semiconductor manufacturing processes and their impact on product design and development

- Experience in managing the life cycle of VLSI products, from design to release and maintenance

Overall, a VLSI Product Engineer plays a critical role in ensuring that VLSI products are designed and developed to meet the specified requirements and standards while adhering to safety and regulatory standards. They also manage the product life cycle to ensure that it meets customer needs and is competitive in the market.

- Published in Engineering

Semiconductor Product Manager

![]()

13. Semiconductor Product Manager

A Semiconductor Product Manager is responsible for managing the life cycle of semiconductor products, from concept to end-of-life. They work closely with other teams, including engineering, sales, marketing, and customer support, to ensure that semiconductor products meet market needs and are delivered on time and within budget.

The job roles of a Semiconductor Product Manager can vary depending on the specific industry and company they work for, but generally, their duties include:

- Conducting market research to understand customer needs and market trends

- Developing product strategies, including product positioning, pricing, and roadmaps

- Collaborating with engineering teams to define product specifications and requirements

- Managing the product life cycle, from concept to end-of-life

- Defining product launch plans and coordinating cross-functional teams to ensure successful product launches

- Managing product budgets, including product costs and pricing

- Providing training and support to sales and customer support teams to ensure successful product adoption and customer satisfaction

- Monitoring product performance and conducting product analysis to identify areas for improvement

- Working with supply chain and manufacturing teams to ensure product availability and quality

- Staying up to date with new technologies, market trends, and customer requirements to continually improve product quality and competitiveness.

Some of the skills required for a Semiconductor Product Manager include:

- Strong understanding of semiconductor technologies, markets, and business models

- Experience in managing the life cycle of semiconductor products, from concept to end-of-life

- Excellent project management skills, including budget management, risk management, and stakeholder management

- Good communication and collaboration skills to work effectively with cross-functional teams

- Analytical and strategic thinking skills to develop and implement effective product strategies

- Knowledge of supply chain and manufacturing processes and their impact on product design and development

- Familiarity with quality management systems and semiconductor design and manufacturing regulatory requirements.

Overall, a Semiconductor Product Manager is critical in ensuring that semiconductor products are designed and developed to meet market needs and delivered on time and within budget. They also manage the product life cycle to ensure that it meets customer needs and is competitive.

- Published in Engineering

Semiconductor Packaging Engineer

![]()

14. Semiconductor Packaging Engineer

A Semiconductor Packaging Engineer is responsible for designing and developing the packaging of semiconductor chips, which includes selecting the materials, creating the layout, and testing the final product.

Their job roles and skills required may vary depending on the specific industry and company they work for, but generally include:

- Developing packaging solutions for semiconductor chips, including designing the layout and selecting the materials to ensure optimal performance and reliability

- Collaborating with cross-functional teams, including design, process, and test engineering, to ensure the packaging meets the requirements of the chip design and manufacturing processes

- Conducting feasibility studies and simulations to determine the best packaging solution for each product and application

- Creating and managing packaging specifications, including environmental and reliability testing requirements, to ensure the packaging meets industry standards

- Overseeing the prototype and sample build process and conducting functional and reliability testing to validate the packaging design

- Identifying and resolving packaging-related issues and working with cross-functional teams to implement corrective actions

- Working with vendors to ensure that the packaging materials and processes meet quality standards and are cost-effective

- Developing and implementing process improvements to increase packaging efficiency and reduce costs

- Staying up to date with new packaging technologies and materials to continually improve packaging design and development processes.

Skills required for a Semiconductor Packaging Engineer include:

- Strong understanding of semiconductor chip design and manufacturing processes

- Experience in semiconductor packaging design and development

- Knowledge of packaging materials and processes, including their impact on chip performance and reliability

- Proficiency in simulation and design tools for semiconductor packaging design and development.

Overall, a Semiconductor Packaging Engineer is critical in ensuring that semiconductor chips are packaged optimally to meet performance and reliability requirements while minimising cost and environmental impact.

These are just a few examples of the many job roles in the semiconductor industry. Other functions include marketing, finance, supply chain management, and more. The initiative offers various opportunities for individuals with various skills and backgrounds, and it continues to be a dynamic and exciting field to work in.

Advantages of pursuing BTech in Electronics and Communication Engineering with Specialisation in VLSI & Embedded Systems at SRM University-AP

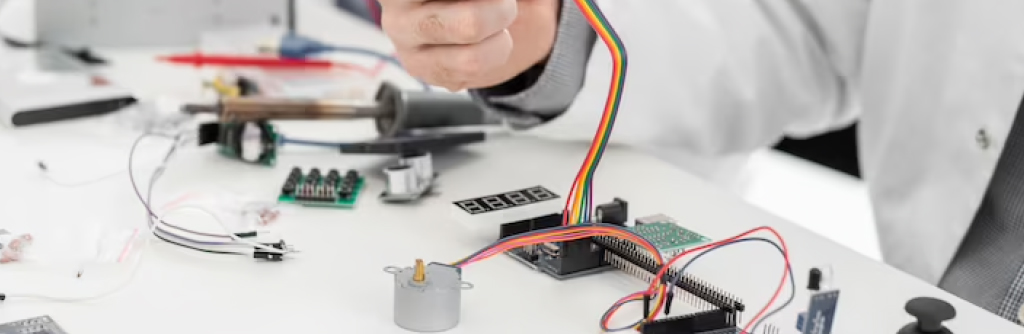

The curriculum is designed to equip students with the technical knowledge, analytical skills, and practical experience needed to develop an in-depth understanding of VLSI design and applications, which will help them to design and develop advanced electronic systems and devices. The curriculum covers various topics, including digital and analog electronic circuits, microprocessors, computer organization and architecture, digital signal processing, communication systems, and programming languages.

The curriculum also includes practical training in VLSI design using industry-standard tools and techniques. Students are trained to design and simulate VLSI circuits, layout and verification of the circuit, and test and debug procedures.

The curriculum is regularly updated to keep up with the latest technological advancements. This ensures that students are equipped with the latest knowledge and skills to succeed in their careers in the electronics and VLSI industry.

- Published in Engineering

Understand the Scientific Reactions Around You with a BSc in Chemistry

Have you always wanted to pursue a career in a specialised field? Are you considering getting an MTech degree?

If so, you’re not alone! Many people are looking to specialise in a particular field, and an MTech degree is one way to do it. This blog post will discuss what it takes to pursue an MTech degree and what to expect from this journey

Why an MTech Degree?

Benefits of Pursuing the Most Sought After Career Option

- Knowledge and Expertise in Technical Subjects

An MTech degree offers an in-depth study of a specific technical subject, allowing you to become an expert in your field. By doing MTech, you not only get knowledge about a particular area but also develop strong communication, problem-solving and analytical skills. You become eligible to work in industry and research fields that require technical expertise.

- Successful Career Prospects

With an MTech degree, one can expect better job prospects and salary packages than with other degrees. It also provides the opportunity to learn highly advanced technologies and equip yourself for a successful career in technology-based organisations. With an MTech degree, one can increase job marketability and become more attractive to potential employers.

- Gateway to Higher Studies and Research

An MTech degree opens the door to further studies or research and may lead to better job opportunities. It is an excellent way for those interested in technology to gain knowledge and better understand the field.

- Specialisations in Your Area of Interest

Aside from this, MTech can also allow students to specialise in a particular area or branch of technology and gain expertise. Moreover, it also opens the door to further research opportunities and postgraduate studies.

- Stay Ahead of the Curve

Studying MTech can be highly beneficial for those looking to advance their career or pursue academic goals in the technology field. With an MTech degree, you can stay up to date with the latest technologies and gain valuable knowledge that will benefit your career and personal life. You can stay ahead of the curve and keep up with the rapidly changing technology industry.

Are you looking for a promising MTech Programme?

The Large Umbrella of MTech Programmes

An MTech degree offers a specialised and advanced education that can give graduates an edge in the job market.

- Materials and Manufacturing MTech Programmes

Materials and Manufacturing MTech programmes provide a deep understanding of Materials Science, Materials Engineering, and Manufacturing processes, which can be applied to a wide range of industries.

Graduates with a Materials and Manufacturing MTech degree can access rewarding and well-paying positions in areas such as,

-

- Aerospace engineering

- Automotive engineering

- Biomedical engineering

– that require expertise in materials and manufacturing technology.

The practical knowledge gained from Materials and Manufacturing MTech studies can help develop new materials for use in production pipelines or create innovative manufacturing processes that streamline production times whilst improving quality control, making the Materials and Manufacturing MTech degree beneficial to the individual graduate and employers alike.

- Surplus Opportunities to Work on Research Projects

Pursuing an MTech degree provides opportunities to work on research projects, which can create networking opportunities and help you hone your skills.

For example, Thermal MTech students get to explore the fascinating field of Thermal engineering, such as Thermal design and Thermal analysis.

They also get to work on projects related to,

-

- Thermal energy management

- Thermal systems design

- Thermal control systems.

- The Bright Side of Thermal Engineering

Working on research projects in Thermal engineering can also give students an edge in the industry as it enhances their understanding of Thermal principles and technologies.

Valuable industry experience and essential connections in the Thermal engineering field through their research work.

All these advantages make pursuing an MTech degree worthwhile for those interested in Thermal engineering.

MTech provides invaluable insight into the latest breakthroughs and technologies in your field, helping you stay ahead of the curve.

Studying for an MTech can provide immense advantages for those in the technological field, particularly IoT technologies. Not only does it offer the opportunity to gain higher qualifications and broaden skills, but it can also provide invaluable insight into the latest IoT breakthroughs and technologies, helping students stay ahead of the curve.

- The Perks of an MTech in VLSI

An MTech in VLSI will allow you to develop advanced knowledge and skills, making a VLSI engineer highly sought after in many industries. As a VLSI engineer, you can work with hardware design, device fabrication, circuit design and debugging, amongst other skills, which will give you a competitive edge over other job applicants.

- Possibilities of the Internet of Things (IoT)

IoT (Internet of Things) related coursework provides students with comprehensive technical and practical insight into IoT systems development. Technical topics like IoT architecture, IoT standards and IoT security are taught in detail, enabling those who complete the program to gain specialised knowledge in the IoT domain.

Furthermore, the programme also typically offers a research-based thesis which enables students to apply their IOT skills to real-world problems. In this way, MTech programmes provide an excellent opportunity for students to understand IoT systems and technologies deeply.

What to Expect From an MTech Degree?

-

- Opportunity to develop their professional skills through hands-on projects and internships

- Opportunity to become experts in Data Science and its associated technologies.

- Data Science is a rapidly evolving field, and an MTech will provide the guidance needed to stay current and be at the forefront of Data Science development.

- Provides students with the ability to gain a deeper understanding of Data Science and its applications, which can help them get better jobs or progress their careers.

Where Will You Be After graduation?

Upon graduation, MTech graduates are highly sought after in the job market, with many top companies offering competitive salaries for those with an MTech degree.

Furthermore, an MTech degree is a tremendous advantage as Thermal graduates are highly sought after in the job market.

Thermal graduates have specialised knowledge, making them more attractive to companies and often offered competitive salaries.

An MTech degree provides Thermal graduates with unique skills and qualifications that make them stand out in the job market and ensure they have a competitive advantage over other applicants.

Making the Most of Your MTech Degree; Yes That’s What Makes the difference!

With an MTech degree, you can pursue a plethora of career options.

What are the Most Coveted Career Options After MTech?

-

-

- Engineering

- Research and development

- Data science

- Materials and Manufacturing

-

- The Scope of Materials and Manufacturing

Materials and Manufacturing are two areas often explored in an MTech course.

-

-

- Provide you with knowledge of materials used in industries and hands-on experience working with them.

- Access to other related fields, such as chemical engineering and robotics.

- Enable you to develop expertise in manufacturing processes, including production planning, cost control and product design.

- On completing the degree, you can embark on a career as a Materials and Manufacturing Engineer with high growth prospects.

- Exclusive job opportunities in the government sector.

-

- The Future of MTech in VLSI

MTech in VLSI empowers students to get VLSI-related roles in the government and even industries like Aerospace, Medical electronics, Automotive industry, etc.

VLSI has become a popular technology due to its versatility in processing large amounts of data without lags. With the proper knowledge and specialised skillset gained through the course, you will be able to face the challenges of a competitive job market more confidently.

What is Stopping You From Grabbing That MTech Degree!

Pursuing an MTech degree can be a rewarding experience. It is an opportunity to gain the skills and knowledge needed to pursue specialised careers in your field of study.

With a vast range of opportunities that come with gaining an MTech degree, it is worth considering if you’re looking for specialised training and education.

With hard work and dedication, you can find great success in your chosen career after completing your MTech degree!

You are just a click away from pursuing your dream MTech Degree!

- Published in Admissions, Blog