Recent News

- Dr Dwivedy and Dr Nagasai Upgrade CMT Technology July 25, 2024

Dr Maheshwar Dwivedy, Associate Dean of Practice School, and Associate Professor, at the Department of Mechanical Engineering, SRM University-AP in collaboration with his post-doctoral scholar, Dr B Prasanna Nagasai, have joined forces to combine artificial intelligence with Cold Metal Transfer (CMT) Technology. Their research paper, “Cold Metal Transfer Technology – A Review of Recent Research Developments,” featured in the Q1 journal, Results in Engineering promises to make a significant impact on automobile, aerospace, oil and gas manufacturing industries, and that’s not all the research will also generate employment opportunities, and empower engineers to deliver enhanced services.

Abstract:

Cold Metal Transfer (CMT) technology has emerged as a promising welding technique, offering numerous advantages such as reduced heat input, minimal spatter, and enhanced control over the welding process. This paper provides a comprehensive review of recent research developments in CMT technology, focusing on its history, variants, recent advancements, and future perspectives. Initially, the paper traces the historical development of CMT welding, highlighting its evolution and the introduction of various CMT variants with distinct characteristics and applications. Recent studies have focused on optimising CMT process parameters to improve weld quality and productivity, leading to advancements in parameter control, arc stability, and wire-feeding mechanisms. Additionally, research has explored the microstructural evolution and mechanical properties of CMT-welded joints for both similar and dissimilar metals, providing insights into material compatibility, joint design, and performance under various conditions. Specific applications such as Laser-CMT hybrid welding, CMT cladding, CMT wire arc additive manufacturing, and CMT welding for repair across various materials are examined, demonstrating the versatility of CMT technology. This review also addresses the challenges and methodologies for defect reduction in CMT welding, along with recommendations for best practices. Furthermore, the paper discusses the integration of artificial intelligence in CMT welding, exploring opportunities for enhanced weld quality, economic, and social implications, and future research directions.

Practical and Social Implications:

The practical implementation of this research on Cold Metal Transfer (CMT) technology can significantly impact various industries, such as automotive, aerospace, oil and gas, and manufacturing. By optimising CMT welding parameters and integrating advanced features like arc length control and waveform modulation, industries can achieve higher weld quality, reduce defects, and enhance productivity. This can lead to more reliable and efficient manufacturing processes, resulting in cost savings and improved product performance. Social implications associated with this research include the potential for increased job opportunities and skill development in the welding and manufacturing sectors. As industries adopt advanced CMT technology, there will be a growing demand for skilled workers trained in these techniques. Additionally, improved welding quality and reduced defects can lead to safer and more durable products, enhancing overall public safety and satisfaction. The integration of artificial intelligence in CMT welding also opens up new avenues for innovation and technological advancements, fostering a culture of continuous improvement and progress in the manufacturing industry.

Collaborations:

Dr V Balasubramanian,

Professor & Director,

Centre for Materials Joining & Research (CEMAJOR)

Annamalai University, Annamalai Nagar-608002, Tamilnadu.Dr P Snehalatha,

Associate Professor & Head

Department of Mechanical Engineering,

Sri Padmavathi Mahila Visvavidyalam, Tirupati, Andhra Pradesh-517502, India.Future Research Plans:

The upcoming work will concentrate on creating Functionally Graded Materials (FGMs) through Wire-Arc Additive Manufacturing (WAAM) by merging nickel and stainless steel. The goal of this research is to leverage the distinct properties of each metal to develop components suited for specialised high-performance applications. The primary challenges involve optimizing the interfaces between materials, refining the deposition processes, and ensuring strong structural integrity throughout the manufacturing process.

The link to the article: https://doi.org/10.1016/j.rineng.2024.102423

Continue reading → - Exploring Wire Arc Additive Manufacturing June 26, 2024

Wire Arc Additive Manufacturing (WAAM) is revolutionizing how we make metal components, especially when it comes to materials like 304L austenitic stainless steel—a popular choice in industries such as aerospace, automotive, and healthcare due to its durability and corrosion resistance. The research paper titled “Microstructural Characteristics and Properties of Wire Arc Additive Manufactured 304L Austenitic Stainless Steel Cylindrical Components by Different Arc Welding Processes” published by Dr Maheswar Dwivedy, Associate Professor, Department of Mechanical Engineering and his post-doctoral scholar Dr B Prasanna Nagasai explores this innovative manufacturing method in detail, focusing on how different welding techniques affect the end product.

Overall, this research indicates that WAAM, with its different welding techniques, can produce 304L stainless steel cylinders that potentially outperform those made by conventional forging, both in terms of material efficiency and mechanical properties. Such findings are significant as they point towards more sustainable and cost-effective manufacturing methods that do not sacrifice quality.

Abstract

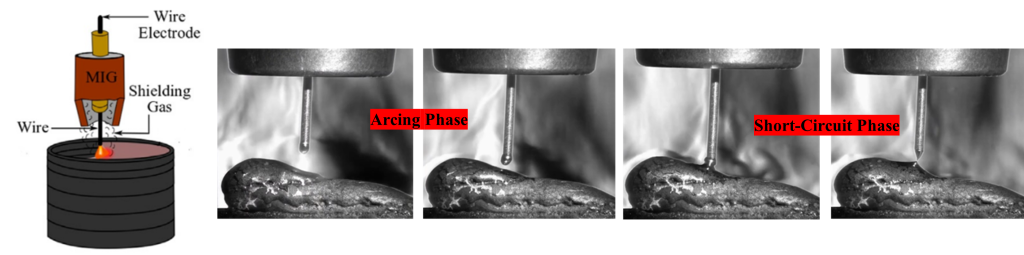

Wire arc additive manufacturing (WAAM) is an advanced additive manufacturing (AM) technology that offers low cost and high deposition rates, making it suitable for building large metal parts for structural engineering applications. However, various welding procedures result in differing heat inputs and repetitive heating treatments throughout the deposition process, which can affect the microstructural and mechanical characteristics of the parts. In the current study, cylindrical parts made of 304L austenitic stainless steel (ASS) were manufactured using the WAAM technique, employing both gas metal arc welding (GMAW) and cold metal transfer (CMT) processes. This study explores the correlation between WAAM techniques and their effects on the bead geometry, microstructure and mechanical properties. The paper presents detailed analyses of the microstructure using techniques such as optical microscopy, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD). The research findings suggest that the choice of arc welding process significantly affects the grain size, phase distribution, and defect formation within the 304L stainless steel, thereby influencing the mechanical properties and overall performance of the manufactured components. The WAAM-processed 304L ASS cylinders showed better performance compared to those manufactured using traditional industrial forging standards, indicating that WAAM-processed 304L ASS cylinders are suitable for industrial applications. This comprehensive evaluation provides insights into optimising welding processes for enhanced quality and performance of stainless steel cylindrical parts.

Highlights of the research

- Controlling heterogeneous microstructures in WAAM-processed 304L stainless steel is challenging.

- GMAW vs. CMT impacts on 304L ASS microstructure analysed.

- The upward growth of coarse austenite/ferrite morphologies is controlled by the wire retraction mechanism.

- CMT produced finer dendrites and more ferrite morphologies.

- WAAM 304L ASS components outperformed the wrought 304L ASS and forged 304L ASS.

Practical implementation/Social implications of the research

The practical implementation of Wire Arc Additive Manufacturing (WAAM) for 304L austenitic stainless steel could revolutionise multiple industries, including aerospace, automotive, medical devices, maritime, and energy, by allowing the production of complex, custom, and durable components with greater efficiency and reduced material waste. This shift not only promises economic benefits like cost reduction and job creation in advanced manufacturing sectors but also carries significant environmental advantages by minimising waste and the carbon footprint associated with traditional manufacturing processes. Furthermore, the technology enhances supply chain resilience by enabling local, on-demand production, which could be crucial during global disruptions. Socially, WAAM could increase access to customised medical aids in low-income regions, fostering greater equality. The adoption of WAAM thus holds the potential to impact manufacturing practices profoundly, driving innovation, sustainability, and inclusivity across various sectors.

Collaborations

Dr V Balasubramanian, Professor & Director, Centre for Materials Joining & Research (CEMAJOR), Annamalai University, Tamilnadu.

In the future, the research team plan to focus on developing Functionally Graded Materials (FGMs) of nickel and stainless steel using Wire Arc Additive Manufacturing (WAAM). This research will aim to leverage the unique properties of each metal to create components with tailored functional performance for demanding applications. Key challenges will include optimising material interfaces, controlling deposition processes, and ensuring structural integrity.

Continue reading → - Teacher-Student Duo Collaborate to Achieve Scientific Excellence June 25, 2024

The Department of Mechanical Engineering at SRM University-AP is proud to present its research paper titled, Study on Properties and Microstructure of Wire Arc Additive Manufactured 2209 Duplex Stainless Steel by Dr Maheshwar Dwivedy and post-doctoral researcher, Dr B Prasanna Nagasai. Below is a brief write-up on their research.

Abstract:

This study investigates the properties and microstructure of 2209 duplex stainless steel (DSS) components fabricated using the wire arc additive manufacturing (WAAM) technique, specifically employing the gas metal arc welding (GMAW) process. The research focuses on the mechanical properties and microstructural characteristics of the produced cylindrical components. Detailed examination revealed that the microstructure varied from the bottom (region ①) to the top (region ②) of the cylinders, with hardness measurements ranging from 301 HV0.5 to 327 HV0.5, and impact toughness values from 118J to 154J. The tensile properties exhibited anisotropic behavior, with ultimate tensile strength and yield strength ranging from 750 to 790 MPa and 566 to 594 MPa, respectively. The study highlights the significant influence of complex heat cycles and cooling rates on the primary phase balance, resulting in a 50/50 austenite/ferrite distribution. Additionally, σ-phase precipitation was observed at the ferrite grain boundaries. The observed increase in austenite content from region ① to region ② is attributed to reduced cooling rates and extended time for solid-state phase transformation. This research provides valuable insights into optimizing the WAAM process for enhanced performance of 2209 DSS components.

Citation Format:

Prasanna Nagasai, B, Maheshwar Dwivedy, Malarvizhi, S. et al. Study on Properties and Microstructure of Wire Arc Additive Manufactured 2209 Duplex Stainless Steel. Metallogr. Microstruct. Anal. (2024). https://doi.org/10.1007/s13632-024-01089-8

Practical implementation:

The practical implementation of this research on Wire Arc Additive Manufacturing (WAAM) for Duplex Stainless Steel (DSS) has significant implications for industries requiring high-strength, corrosion-resistant components, such as construction, marine, and chemical processing. By optimizing the WAAM process to produce DSS parts with balanced microstructures, manufacturers can create durable and efficient parts more cost-effectively and with less material waste than traditional methods. This advancement could lead to more sustainable manufacturing practices, reducing the environmental impact and operational costs associated with producing large metal components. Socially, the widespread adoption of this technology could drive innovation, create new job opportunities in advanced manufacturing, and contribute to the development of stronger, longer-lasting infrastructure and machinery, ultimately benefiting the economy and society at large.

Collaborations:

Dr V Balasubramanian,

Professor & Director,

Centre for Materials Joining & Research (CEMAJOR)

Annamalai University, Annamalai Nagar-608002, Tamilnadu.Dr P Snehalatha,

Associate Professor & Head

Department of Mechanical Engineering,

Sri Padmavathi Mahila Visvavidyalam, Tirupati, Andhra Pradesh-517502, India.Future Research Plans:

In our upcoming work, we will focus on developing Functionally Graded Materials (FGMs) using Wire Arc Additive Manufacturing (WAAM), combining nickel and stainless steel. This research aims to harness the unique properties of each metal to create components tailored for specialized applications requiring high performance. Key challenges include optimizing material interfaces, refining deposition processes, and ensuring robust structural integrity throughout production.

The link to the article– https://doi.org/10.1007/s13632-024-01089-8

Continue reading → - Dr Maheshwar Publishes Significant Research in Materials Letters June 19, 2024

In a remarkable achievement, Dr Maheshwar Dwivedy, Associate Professor in the Department of Mechanical Engineering, has made a significant contribution to the field of materials science with his latest publication. The paper, entitled “Understanding heterogeneity and anisotropy of duplex stainless steel elastic/plastic nature through property mapping technique,” has been published in the esteemed journal Materials Letters, which boasts an impact factor of 3.0.

In a remarkable achievement, Dr Maheshwar Dwivedy, Associate Professor in the Department of Mechanical Engineering, has made a significant contribution to the field of materials science with his latest publication. The paper, entitled “Understanding heterogeneity and anisotropy of duplex stainless steel elastic/plastic nature through property mapping technique,” has been published in the esteemed journal Materials Letters, which boasts an impact factor of 3.0.Dr Dwivedy’s research provides insightful analysis of the complex behaviours of duplex stainless steel, a material known for its high strength and corrosion resistance. By employing a property mapping technique, the study reveals the intrinsic heterogeneity and anisotropy of the material’s elastic and plastic properties. This groundbreaking work not only advances the understanding of duplex stainless steels but also opens up new possibilities for their application in various industries.

The publication of this paper in a journal with a significant impact factor is a testament to the quality and importance of the research conducted by Dr Dwivedy and his team. It underscores SRM University – AP’s commitment to fostering cutting-edge research and innovation.Abstract

Accelerated property mapping, an advanced indentation technique, was used to describe the nanomechanical behaviour of duplex stainless steel (DSS) surfaces prior to and post-heat treatments. Heterogeneity in deformation responses and relative elastic and/or plastic nature of DSS was assessed on longitudinal and transverse directions through load-displacement curves, property maps, histograms of hardness (H), modulus (E) and indentation works. Empirical ratios such as H/E, (H/E)1/2, H3/E2 and plasticity index were employed to understand the anisotropy across the directions. It is crucial that for structural designing, heterogeneity and anisotropy of mechanical behaviour need to be accounted for improved property–optimisation.Explanation of the Research in Layperson’s Terms

Duplex stainless steel (DSS), a unique category of steel, contains almost equal amounts of ferrite and austenite phases within its microstructure. These are employed in applications like boilers, pressure vessels, heat exchangers, etc., as they offer superior strength, ductility, toughness, and corrosion resistance properties compared to other steels. Mechanical characteristics of DSS are significantly influenced by manufacturing protocols including heat treatments. It is believed that anisotropy and heterogeneity in mechanical behaviour can be driven by microstructures post-material processing.

A comprehensive understanding of DSS material behaviour at the macroscopic scale is not feasible without knowledge of its features and their properties locally. Although the mechanical properties of DSS have been widely explored from a macroscopic perspective as well as innovative nano-scale property mapping techniques, the number of studies addressing anisotropy seen through small-scale characterization is rather restricted. In general, the preliminary assessment of the mechanical behaviour commonly done through hardness (H) and modulus (E) properties. For estimating the elasticity and/or plasticity of material or any surface, different empirical ratios were adopted namely H/E, H3/E2 and (H/E)1/2.

Practical Implementation or the Social Implications Associated

Continue reading →

• This study demonstrates the notable differences in mechanical properties in longitudinal and transverse directions along with heterogeneity before and after heat treatments.

• It is felt crucial that for structural designing, heterogeneity and anisotropy of mechanical behaviour need to be accounted for improved property-optimisation. - Patent Granted for Research in Developing Tarnish Resistant Silver Alloys May 7, 2024

Yet another groundbreaking achievement for the researchers at SRM University-AP! Prof. Ranjit Thapa, Dean-Research and Professor, Department of Physics, Prof. G S Vinod Kumar, Professor and Head, Department of Mechanical Engineering and Ms Harsha K, PhD scholar, continue to make their mark in the university’s excellent research legacy by having their patent “Tarnish Resistant Silver Composition and a Process for its Preparation” being granted by the Indian Patent Office. This innovative research team has used density functional theory to explain the tarnishing of silver. Their work also focuses on finding alloying elements that protect silver.

Abstract

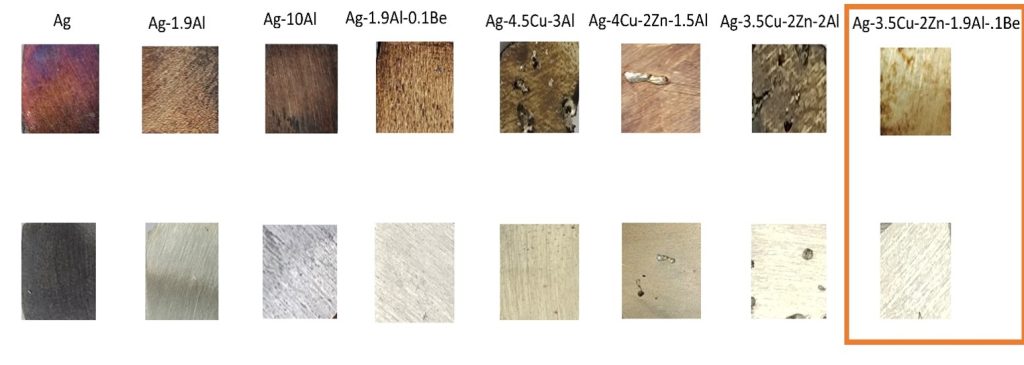

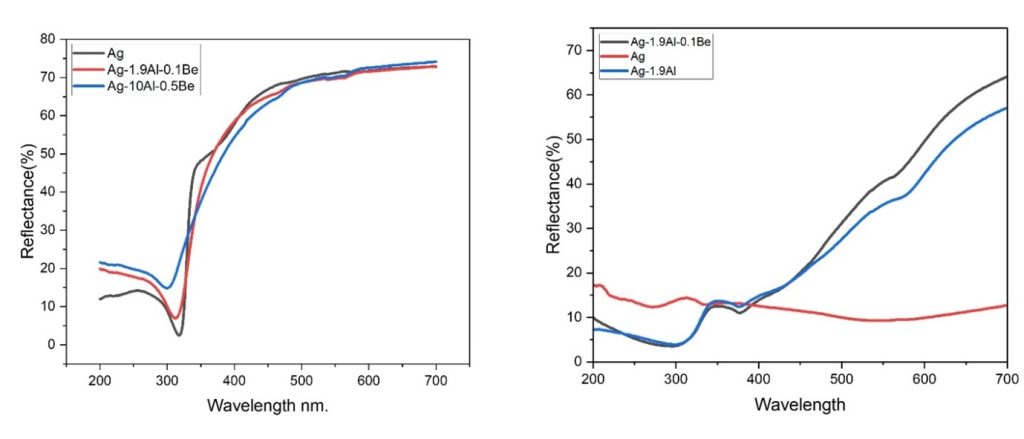

The research is on the development of tarnish-resistant silver alloys from an experimental and computational perspective. With time, silver atoms on the surface of the metal undergo sulphidation and form Ag2S molecules. These particles will accumulate to form a layer whose thickness goes beyond 10nm, and then the human eye will start to find a discolouration on the surface of silver, which is tarnish. The stain colour changes from light yellow to dark brown. This reduces the lustre of silver and makes them aesthetically non-pleasing. The silver jewellery and articles manufacturing industry suffers from this tarnishing as it leads to the loss of material and money and ruins intricate designs made of silver. The research study attempts the problem by alloying silver with appropriate elements, which are computationally checked and verified. The team works with alloying elements such as Cu, Zn, Ge, Ti, Zr, Mg, Al, and Be. Along with tarnish resistance, the proposed alloys maintain high reflectance, good hardness, and excellent workability when spinning.

Figure.1 The images of different silver alloys after accelerated tarnish test in as-cast condition (first row) and after undergoing passivation heat treatment at 450°C for 1 hour in the presence of oxygen (second row).

Practical implementation/social implications of the research

- Stainless silver is in demand as customers want their precious metal articles to be kept for a longer time as heirlooms. So, the product that we could develop out of our composition will be making more demand for silver.

- It can increase the market potential of silver.

- It can lead to more innovations in the jewellery industry.

Collaborations

- Waman Hari Pethe

- Ashlyn Chemmannur

- TITAN

The team would continue to work on the scope of research to develop more tarnish-resistant compositions, improve the tensile strength, scratch resistance, surface hardness, and workability of silver alloys and find novel elements which can add to desirable properties of silver.

Continue reading →

Figure.2 Reflectance of alloys (a) before tarnish test (b) after tarnish test