Recent News

- Chemistry Student Secures Prestigious HEST Scholarship March 25, 2025

Department of Chemistry is proud to announce that Mr M V R Akshay Sampath, 3rd year BSc. Chemistry student has been selected for the HEST Scholarship, India’s largest Higher Education Scholarship Test powered by WeMakeScholars, an organisation funded and supported by the Ministry of Electronics & Information Technology (MeitY), Govt. of India under the ‘Digital India’ campaign. Through this scholarship, Mr Sampath is eligible for scholarship funding of ₹3 lakhs, which can be utilized towards tuition fees, academic expenses, or travel costs for higher education.

Along with academics, Akshay is working in the functional nanomaterials laboratory under the supervision of Dr Sabyasachi Chakrabortty and in computational chemistry research under the supervision of Dr Baswanth V S Oruganti, Chanakya University, Bangalore. This opportunity significantly supports his aspirations for higher education and research in the branches of bio-photonics and material science in the top research-intensive universities globally in countries like Germany, UK, Ireland, and the USA.

Continue reading → - Synthesising Flexible Solid-state Electrolytes for Electronic Devices January 29, 2025

Dr Chinmoy Das, Assistant Professor from the Department of Chemistry, and scholars Mr Sushant Wakekar and Mr Sasikumar K have published their invention titled “Li-based solid-state electrolyte and a method for its preparation” in the Indian Patent Office (Patent application No. 202441083351). The invention illustrates how to synthesise inexpensive Li(I) ion-based solid-state electrolytes that are feasible for fabricating flexible electronic devices. The team worked on inexpensive and readily available starting materials that provide self-supported and flexible solid-state electrolytes to advance LIB applications.

Abstract

In our invention, we described a rapid and robust synthetic methodology to prepare novel flexible solid-state electrolytes (SSEs) suitable for the fabrication of eco-friendly lithium-ion batteries (LIBs). The mechanically flexible film has been synthesized upon in situ incorporation of Li(I) ion into two inexpensive biocompatible polysaccharide matrices through mixing. We achieved Li(I) ion-based superionic conductivity at room temperature which is feasible for the fabrication of flexible electronics in modern age society.

Practical Implementation/Social Implications of the Research

This invention can be implemented in various industries, such as electric vehicles (EVs), wearable and flexible electronics, and aerospace and aviation.

The team is extending their research towards the fabrication of cheaper sodium (Na+), potassium (K+)-ion based solid-state electrolytes with superionic conductivity and implementing them in designing the biodegradable sodium-ion / potassium ion batteries (NIBs / KIBs).

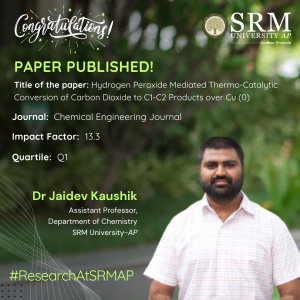

Continue reading → - Dr Kaushik’s Research on Hydrogen Peroxide Mediated Thermo-Catalytic Conversion of Carbon Dioxide December 26, 2024

Dr Jaidev Kaushik, Assistant Professor from the Department of Chemistry, has introduced an innovative method for converting CO₂ emissions into valuable products like acetic acid, offering a sustainable solution to combat climate change. His groundbreaking research has been published in the Chemical Engineering Journal under the title, Hydrogen Peroxide Mediated Thermo-Catalytic Conversion of Carbon Dioxide to C1-C2 Products over Cu(0).

Dr Jaidev Kaushik, Assistant Professor from the Department of Chemistry, has introduced an innovative method for converting CO₂ emissions into valuable products like acetic acid, offering a sustainable solution to combat climate change. His groundbreaking research has been published in the Chemical Engineering Journal under the title, Hydrogen Peroxide Mediated Thermo-Catalytic Conversion of Carbon Dioxide to C1-C2 Products over Cu(0).A Brief Abstract:

The global challenge concerning CO2 conversion to valuable products is anticipated to play a critical role towards net zero carbon emissions. Thermal CO2 reduction is advantageous in terms of higher conversion rates, selectivity, and already-established industrial thermal instruments for scalability. However, the method is energy-intensive, a hindrance to sustainably practical adoption. Herein, we present a comprehensive study of H2O2-mediated thermal CO2 conversion in the presence of dendritic zerovalent copper (d-ZCu) in a batch-type reactor, yielding C1 and C2 carbon products, with acetic acid (AcOH) as the major product (achieving an optimized yield of approximately 0.98 M and a selectivity of around 97% at near-ambient conditions of 25-150°C and 1-15 bar), along with trace amounts of methanol and ethanol, and carbon monoxide (CO) as a gaseous product. The reaction parameters, including temperature, time, pressure, and concentrations, were optimized to gain better insight into the reaction. To further explore the feasibility of the process, experiments were conducted in a continuous flow-packed bed reactor using similar parameters as those in the batch reactor, where CO was identified as the primary product of CO2 reduction. For advanced real-life applicability, the as-emitted exhaust gases from diesel and petrol engines, as sources of anthropogenic CO2, were utilized to establish the practical applicability of the proposed method.

Explanation in Layperson’s Terms:

In our work, we found a way to convert CO2, a gas that contributes to climate change, into useful products. We used hydrogen peroxide and a special type of copper catalyst (zerovalent and dendritic shaped) to change CO2 into things like acetic acid (used in vinegar), methanol, ethanol, and carbon monoxide. The main product we made was acetic acid, and the process worked well at lower temperatures and pressures, which means it used less energy. To see if this could be useful in real life, we tested it with CO2 coming from car exhaust, including diesel and petrol engines, and found that it could help reduce pollution. This shows that our method could be a practical way to reduce CO2 emissions from everyday sources.

Practical Implementation and Social Implications:

The practical implementation of our research offers a promising solution for reducing CO2 emissions by converting this harmful gas into valuable products like acetic acid, methanol, ethanol, and carbon monoxide. We used hydrogen peroxide and a dendritic zerovalent copper to operate our method at lower temperatures and pressures, making it more energy-efficient than traditional CO₂ reduction techniques. The implementation of this approach may not only help industries reduce their carbon footprint but also provide economic value by synthesizing widely used products. A key social benefit is its potential to capture and convert CO2 emissions from everyday sources, such as car exhaust, demonstrating how this method can help reduce pollution in urban environments. Overall, this technology supports the global effort to achieve net-zero carbon emissions, offering a practical and scalable solution for industries and everyday applications alike.

Collaborations:

Dr Sumit Kumar Sonkar (MNIT Jaipur, India)

Future Research Plans:

- The adsorption/photodegradation-assisted quick and efficient removal of next generation advanced pollutants such as microplastic, pesticides, pharmaceutical waste, etc. by hydrophobic carbon aerogel and their doped and functionalized versions.

- Utilizing waste derived heterogeneous catalysts in organic transformation reactions.

- Selective sensing of toxic metal ions/biomarkers/biomolecules using fluorescent nanomaterials.

- Upcycling of carbonates/CO2 via photo/thermal assisted reactions to get C1 and C2 hydrocarbons (green fuel).

The link to the article

https://www.sciencedirect.com/science/article/abs/pii/S1385894724082779

Continue reading → - Inspiring Future Chemists at ChemZeal 3 December 3, 2024

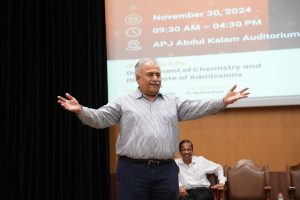

On November 30, 2024, the Department of Chemistry, in collaboration with the Directorate of Admissions, hosted ChemZeal 3, a flagship event that showcased the ever-expanding scope of chemistry in today’s world. The event was graced by prominent personalities, including the Chief Guest, Prof. Vijayamohanan Pillai, Dean of Research & Development at IISER Tirupati, and Dr Veerababu, Director of Cathode, GODI India Pvt. Ltd., Hyderabad, who served as the resource person.

On November 30, 2024, the Department of Chemistry, in collaboration with the Directorate of Admissions, hosted ChemZeal 3, a flagship event that showcased the ever-expanding scope of chemistry in today’s world. The event was graced by prominent personalities, including the Chief Guest, Prof. Vijayamohanan Pillai, Dean of Research & Development at IISER Tirupati, and Dr Veerababu, Director of Cathode, GODI India Pvt. Ltd., Hyderabad, who served as the resource person.The event began with a welcome address by the convener, Dr Satheesh Ellipilli, who provided an insightful overview of the programme and reflected on the immense success of the previous editions, ChemZeal 1 and 2. He expressed excitement about the growth of the event and its contribution to advancing the knowledge and application of chemistry in various fields.

Following the welcome, the Head of the Department of Chemistry delivered an inspiring speech, offering a comprehensive overview of the department. Dr Pardha Saradhi Maram, Associate Professor and Head highlighted the department’s commitment to academic excellence, research innovation, and fostering an environment where students can explore the transformative power of chemistry.

One of the major highlights of the event was the launch of the “Post a Q” portal by Vice Chancellor, Prof. Manoj K Arora. The portal aims to provide a platform for students and researchers to ask questions and seek solutions in the realm of chemistry. During the launch, Prof. Arora remarked, “Chemistry is such a wonderful science that, no matter what you think of, you will find chemistry in it.” This statement underscored the far-reaching impact of chemistry on everyday life and innovation.

The keynote address by the Chief Guest, Prof. Vijayamohanan Pillai, focused on generating and storing clean energy. He discussed the pivotal role that chemistry plays in developing sustainable solutions for energy storage and generation, from battery technologies to renewable energy sources. Prof. Pillai’s talk resonated with the audience, particularly in the context of the growing need for clean energy in the face of global environmental challenges.

The resource person, Dr Veerababu, shared valuable insights into cathode materials and their applications in the energy sector. His expertise in battery technology and his role at GODI India added depth to the discussions, providing students and faculty with a practical perspective on the industry’s current advancements.

ChemZeal 3 successfully fostered a spirit of collaboration and intellectual curiosity, highlighting the dynamic nature of chemistry and its potential to address some of the world’s most pressing issues. The event concluded with a vote of thanks, acknowledging the contributions of all the speakers, participants, and organisers who made the day a resounding success.

Continue reading →