High-entropy alloys (HEAs) are gaining research significance in recent times as they propose novel alloy designs and concepts demonstrating better performance. HEAs constitute multiple principal elements in varying concentrations and combinations to produce new materials with excellent physical properties and superior performance at extreme temperature conditions. Recent studies have brought out a few high-entropy alloys possessing exceptional properties, even capable of challenging the existing theories and models for conventional alloys. However only very little has been explored within this multidimensional space leaving limitless possibilities to be explored and materialized.

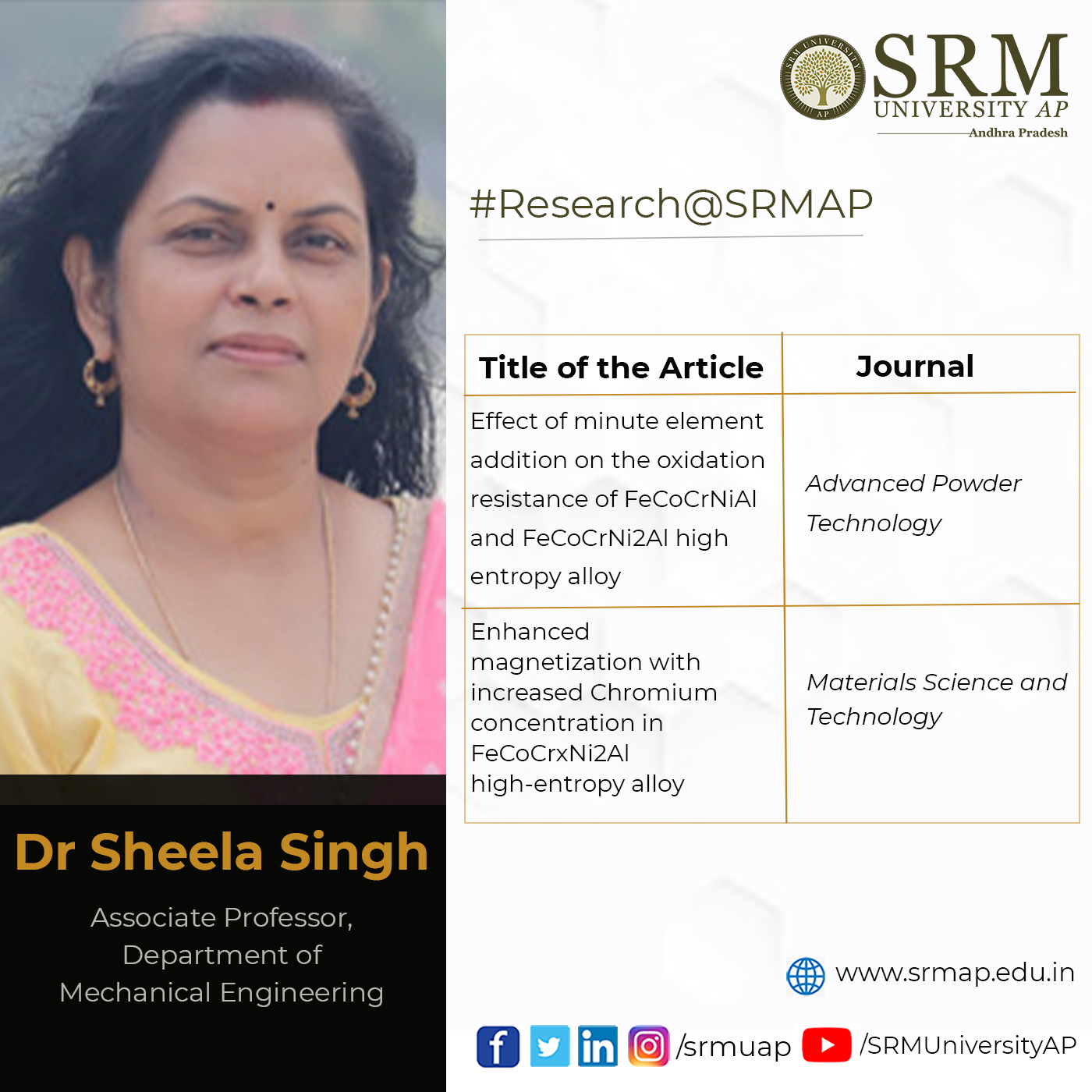

Dr Sheela Singh, from the Department of Mechanical Engineering, has been conducting rigorous research in this domain and she has published research articles proposing novel ideas to tweak the properties of HEAs. In one of the articles co-authored by Dr Sheela, “Effect of minute element addition on the oxidation resistance of FeCoCrNiAl and FeCoCrNi2Al high entropy alloy”, published in the journal Advanced Powder Technology, she investigates the effect of Ti0.1 and Ti0.1Si0.1 addition on the high-temperature isothermal oxidation behaviour of dense FeCoCrNiAl and FeCoCrNi2Al high entropy alloys.

Mechanical properties such as hardness & young’s modulus, thermal properties such as melting temperature, specific heat capacity and coefficient of thermal expansion (CTE) were investigated by Nano hardness tester (NHT), differential scanning calorimetry (DSC) and dilatometer, respectively. The phases present in the HEAs produced by hot vacuum pressing and after isothermal oxidation were characterized by X-ray diffraction, Scanning Electron Microscopy and Raman Spectroscopy.

The weight gain recorded after isothermal oxidation for 5,25,50 and 100 hours at 1050°C was found to be parabolic in nature. X-ray diffraction analysis (XRD), as well as Raman spectroscopy analysis of HEA’s oxidized at 1050°C for 100 hours, shows the formation of the Al2O3 phase. A homogeneous thin oxide scale without any discontinuity was observed throughout the cross-section. It has been confirmed that Ti & Si addition in minute amount (0.1 at. % each) improves the mechanical properties and oxidation resistance as well as reduces the waviness of the oxide scale.

Another article co-published by her, “Enhanced Magnetization with Increased Chromium Concentration in FeCoCrxNi2Al High-Entropy Alloy”, in Materials and Science Technology, reports the effect of increasing the concentration of antiferromagnetic element Cr in FeCoCrxNi2Al (x = 0.5, 1.5) High Entropy Alloy (HEA) on their magnetic properties. It was found that the structure and composition of different phases, and the likely degree of spinodal decomposition in the Cr-Fe rich BCC phase significantly affects the magnetic properties.

Interestingly, the sample with Cr concentration x=1.5 showed two times larger saturation magnetization as compared to x=0.5. Furthermore, the magnetization versus temperature response shows a multi-phase character and exhibits distinct behaviour in low temperature and high-temperature regimes in both samples. The obtained soft ferromagnetic behaviour of these HEAs is crucial for the development of a new class of HEA for various applications.

The considerable structural and functional potential, as well as the richness of design, make HEAs promising candidates for new applications prompting further studies in the field. There remains a vast compositional space that is yet to be discovered. New studies have to be initiated finding out effective ways to recognise regions within this space where high-entropy alloys with potentially interesting properties may be lurking. Dr Sheela’s research is a right step in this direction to pave the way for fruitful developments in the future.