Closed-cell metal foams are crucial to heavy industry machinery as they primarily function as impact-absorbing materials. Stabilizing closed-cell metal foams is a pivotal element in the process of manufacturing closed-cell metal foams. On this note, Prof GS Vinod Kumar from The Department of Mechanical Engineering has published a paper entitled Production, stability, and properties of in-situ Al–5ZrB2 composite foams in the journal Materials Science and Engineering: A with an impact factor of 6.044.

Abstract

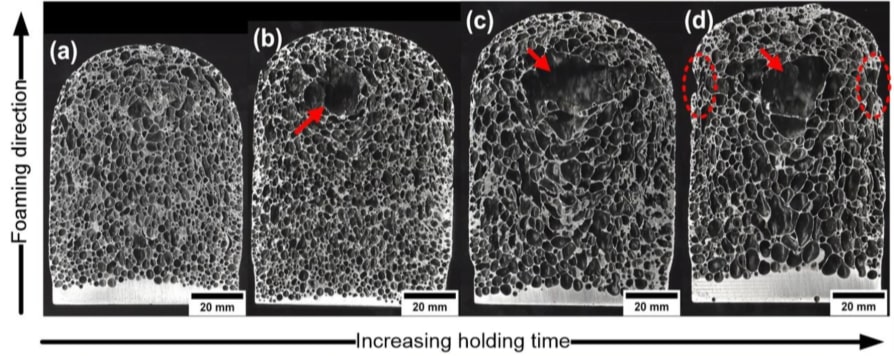

Stabilization is an essential requirement to produce closed-cell metal foams. In the melt route of foaming, usually ceramic particles are used as foam stabilizers. For the first time, the present study introduces ZrB2 particles as foam stabilizers. We demonstrate the foaming of in-situ based Al composite containing submicron ZrB2 particles. The effect of foaming temperature and holding time on the structural and mechanical properties of the foams was studied. The composites and foams were characterized using XRD, SEM/EDS, and optical scanning techniques. The mechanical properties of the foams were determined by subjecting the foams to a quasi-static compression test. Submicron ZrB2 particles present in the cell wall and at the gas-solid interface promoted foam stability. All the foams exhibited a good cellular structure with high expansion. Among the foams, the foams prepared at 680 ºC with a holding time of 120 s exhibited the smallest cell size and the best mechanical properties. The structural and mechanical properties of the Al–5ZrB2 foams were found to be comparable to conventional foams.

Novel in-situ ZrB2 particles were produced to form Al-5ZrB2 composites. ZrB2 particles present in the melt tend to stabilize the H2 gas bubbles produced from the decomposition of TiH2. The macrostructure was best observed when foamed at 680 ºC and held for 120 sec. Because of its finer pores ( ̴ 3mm ), excellent compressive strength and energy absorption capacity was exhibited comparable to conventional Al foams.

The paper observes a wide-range of possibilities for the application of in-situ Al–5ZrB2 composite foams to modify bullet proof vests, car body parts, sound and heat proof walls in theatres, naval ship bodies, etc.

Prof Vinod Kumar also discusses the future application of this technique in use of metallic powders as blending agent for effective dispersion of blowing agent in the melt and in the field of compressive and energy absorption studies for Al composite foams.